Empty environmental commitments from governments, falling bitumen quality and the impact of the economic crisis - DenimoTech asked some of its global distributors about the challenges of today’s markets - Kristina Smith was there to listen in

Competition from Chinese manufacturers; highways abandoned half-built; the worst year for road building in the last 20 years. These are challenging times forLast month, Denimo Tech brought together five of its 14 distributors at its headquarters in Arslev, Denmark, to brief them on new product developments and to find out what is happening on the front line. Covering a diverse range of regions including South East Asia, North Africa, China, Western and Eastern Europe, these firms supply equipment, chemicals and technical know-how to asphalt suppliers and contractors.

Against the backdrop of the economic crisis, these firms are battling to open minds – and budgets – to the wider range of applications which are possible with bitumen emulsions. As a potential cold technology which could save energy – and the environment – bitumen emulsions should be gaining in popularity.

However, it seems that governments’ rhetoric on cutting carbon emissions has remained just that, with capital cost now the overriding concern. “In 1998 we had the Iberian Congress in Spain. Everybody came away from the conference thinking that we had lots of projects with green solutions on their way. Up until now, we never saw one,” said Hugo Guimarães, CEO of WeedsWest which is based in Portugal but also works in countries including Mozambique, Angola and Equatorial Guinea.

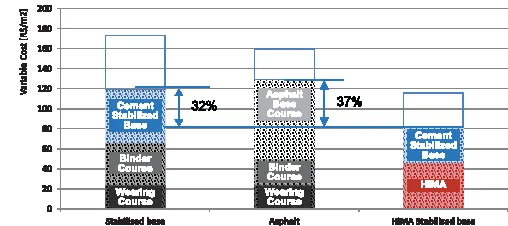

For contractors to consider new technologies, cash savings must be on the table, says Zoran Krusic, deputy managing director of

In Ukraine, Prologue has taken a proactive stance in the downturn, opening a laboratory and running training sessions in bitumen emulsion technology. “When conditions change and road enterprises start to think about buying something for emulsions, they will come to us,” said Anatoliy Baback, head of the firm’s technical department.

Michael Tan, managing director of

This process has already begun, said Tan, with one Korean firm looking at replacing 20% of bitumen with Carbon Black and a Chinese supplier working with Coal Tar Pitch.

“Eventually there will be a lack of bitumen,” agreed Krusic. “I think we should focus our efforts on technologies such as rejuvenating old binders to slow down consumption.”

In China, Nico Zhang Yi, vice-general manager of

Some European contractors are also buying Chinese kit, says Guimarães, but for most customers, reliability and after-sales care are more important considerations. “Sometimes, that’s worth more than money,” said Guimarães.

Around the table, people agreed on the difficulty of introducing new technologies. Several had accounts of new surfacing techniques beginning to gain ground, only to be stopped in their tracks at the first sign of failure.

“Governments won’t take the risk,” said Guimarães. “Until they are able to take the risk, we are not able to supply them with what they don’t want.”

“Cold recycling started very strongly in the Balkans,” said Krusic. “And microsurfacing also made a good start. But at the first failure, it stopped for a long time. Sometimes it feels like everybody is waiting for the mistakes, rather than supporting new technology.”

Tan explained the growth of microsurfacing in China, introduced in 1990 but stalled for a decade due to early teething problems.

Then in 2000

Tan’s conclusion is this: “If you want to do a demonstration trial project onsite for a new emulsion technology, you need to take control of the whole project from A to Z, including lab testing, mix design, emulsion production, onsite operation. Otherwise it will have a greater risk of failure, slowing down development of new techniques.”

Quality conscious FART chooses Massenza

Polish roads constructor and supplier

“Thanks to this new investment, FART can now produce PMB for its own sites increasing the quality of the final asphalt hot mixes,” said FART’s general manager Szczukiewicz Miroslaw. “Our aim is to start a new asphalt production utilising Polymer Modified Bitumen. This will enable us to better manage the PMB production operation ensuring the highest quality of the hot mix produced by FART”.

Founded in 1999, FART’s business is mainly focused on road and bridge construction, stone and asphalt mixes for the road industry, concretes and special mixes, and special industrial surfaces for parking, bus lanes and similar. With a head office located in Kielce, around 200km south of Warsaw, FART employs over 300 employees and owns two asphalt mixing plants.

Since its beginnings in 1999, FART has grown steadily over the years, with local awards and a Forbes Diamond award in 2012 recognising its impressive income growth.

The Massenza PMB plant was commissioned in the Spring, with FART reporting that its staff are very satisfied with the new equipment’s performance.