An upfront combination of both cost savings and reduced environmental impact are now possible as a result of Kraton Polymers' continued investment in polymer innovation, says the company. "The new polymers enable a reduction in the bound pavement thickness by allowing the use of highly polymer modified bitumen (PMB) base course binders without excessive viscosities or incompatibility problems. The step change improvements in binder strength, flexibility and toughness result in a dramatic improvement in asph

February 28, 2012

Read time: 3 mins

An upfront combination of both cost savings and reduced environmental impact are now possible as a result of 715 Kraton Polymers' continued investment in polymer innovation, says the company.

"The new polymers enable a reduction in the bound pavement thickness by allowing the use of highly polymer modified bitumen (PMB) base course binders without excessive viscosities or incompatibility problems. The step change improvements in binder strength, flexibility and toughness result in a dramatic improvement in asphalt fatigue resistance, even in hard binders, making the thickness reduction possible," says Kraton Polymers.

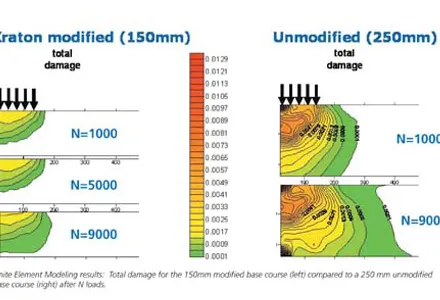

Thickness reductions of 40% were evaluated in a Finite Element Model by the well-respected Road Research Laboratory of the Delft University of Technology in the Netherlands, comparing an unmodified pavement with the new highly modified solution. Even with reduced thickness, the resulting damage in the heavily modified solution was significantly lower (see figure. The model used is a dynamic finite element model for asphalt pavements. It utilises a sophisticated characterisation of the asphalt, based on a set of data measured on asphalt mix, which includes compressive and tensile testing verified by fatigue testing.

According to Kraton Polymers, the cost reductions from raw material outweigh the added cost of modification, hence a substantial upfront cost saving is expected, while also extending the pavement's lifetime. The substantial reduction in environmental impact, aggregate and bitumen far outweigh the small addition of these new polymers.

While reducing pavement thickness can result in construction cost reductions, additional cost savings and performance benefits can be realised where pavement thickness limitations exist. For example, adjustments for bridge or tunnel clearances, or the need to move sewers down, raise pedestrian pavements or modify guard rail heights when upgrading existing roads can be prevented.

To demonstrate the value in a real world setting, Kraton Polymers will have its solution tested at the independent and highly respected pavement testing facility: the National Center for Asphalt Technology (NCAT) associated with the University of Auburn in Alabama, USA, starting mid-2009.

The test sections on the oval track will be loaded with multiple manually driven heavy trucks over a two-year period for a total of 10 million equivalent single axle loads. Instrumentation will continuously generate results, allowing early feedback on the performance improvement relative to a typical standard solution.

"As just one application of highly modified binders, base course thickness reduction clearly demonstrates Kraton Polymers' commitment and continued investment in innovative polymer solutions to the paving industry," says the company.

This was taken from a fuller account (Taking the benefits of polymer modification to the base course) prepared by Kraton Polymers, which can be found at: %$Linker:External 0 0 0 oLinkInternal www.worldhighways.com World Highways false http://www.worldhighways.com/ false false %>

"The new polymers enable a reduction in the bound pavement thickness by allowing the use of highly polymer modified bitumen (PMB) base course binders without excessive viscosities or incompatibility problems. The step change improvements in binder strength, flexibility and toughness result in a dramatic improvement in asphalt fatigue resistance, even in hard binders, making the thickness reduction possible," says Kraton Polymers.

Thickness reductions of 40% were evaluated in a Finite Element Model by the well-respected Road Research Laboratory of the Delft University of Technology in the Netherlands, comparing an unmodified pavement with the new highly modified solution. Even with reduced thickness, the resulting damage in the heavily modified solution was significantly lower (see figure. The model used is a dynamic finite element model for asphalt pavements. It utilises a sophisticated characterisation of the asphalt, based on a set of data measured on asphalt mix, which includes compressive and tensile testing verified by fatigue testing.

According to Kraton Polymers, the cost reductions from raw material outweigh the added cost of modification, hence a substantial upfront cost saving is expected, while also extending the pavement's lifetime. The substantial reduction in environmental impact, aggregate and bitumen far outweigh the small addition of these new polymers.

While reducing pavement thickness can result in construction cost reductions, additional cost savings and performance benefits can be realised where pavement thickness limitations exist. For example, adjustments for bridge or tunnel clearances, or the need to move sewers down, raise pedestrian pavements or modify guard rail heights when upgrading existing roads can be prevented.

To demonstrate the value in a real world setting, Kraton Polymers will have its solution tested at the independent and highly respected pavement testing facility: the National Center for Asphalt Technology (NCAT) associated with the University of Auburn in Alabama, USA, starting mid-2009.

The test sections on the oval track will be loaded with multiple manually driven heavy trucks over a two-year period for a total of 10 million equivalent single axle loads. Instrumentation will continuously generate results, allowing early feedback on the performance improvement relative to a typical standard solution.

"As just one application of highly modified binders, base course thickness reduction clearly demonstrates Kraton Polymers' commitment and continued investment in innovative polymer solutions to the paving industry," says the company.

This was taken from a fuller account (Taking the benefits of polymer modification to the base course) prepared by Kraton Polymers, which can be found at: %$Linker: