“The idea has been in my head for a long time,” said Albrecht. “If we were making bitumen for a purpose, rather than taking a residue, how would we re-engineer it? What would it be like if we were making the product for a specific purpose?”

Apart from the fact that Instant Asphalt does not rely on refineries for any of its ingredients, it could have other potential benefits. It is made up of two elements – a powder and a liquid – which are combined to form the bitumen or asphalt. This could make Instant Asphalt a good solution for remote locations which currently rely on asphalt drums of cold bitumen, said Albrecht.

“This would be a good substitute for drums, which require very intensive energy to reliquefy the bitumen,” said Albrecht. “Drums also tend to become an environmental nuisance. There are thousands and thousands of them, lying around.”

Bitumen is usually made from the residues that remain after crude oil has been processed. The components of these residues have changed over the years. Some refineries have been upgraded to produce more valuable products than bitumen, some are using lighter oils that produce less residue, and some have been closed down altogether because they don’t make money, which means that bitumen has to come from further afield.

Bitumen is usually made from the residues that remain after crude oil has been processed. The components of these residues have changed over the years. Some refineries have been upgraded to produce more valuable products than bitumen, some are using lighter oils that produce less residue, and some have been closed down altogether because they don’t make money, which means that bitumen has to come from further afield.

“What Instant Asphalt shows is that even if refineries are shutting down, we can still make bitumen; there are other ways of doing it,” said Albrecht. “We are not dependent on big oil companies.”

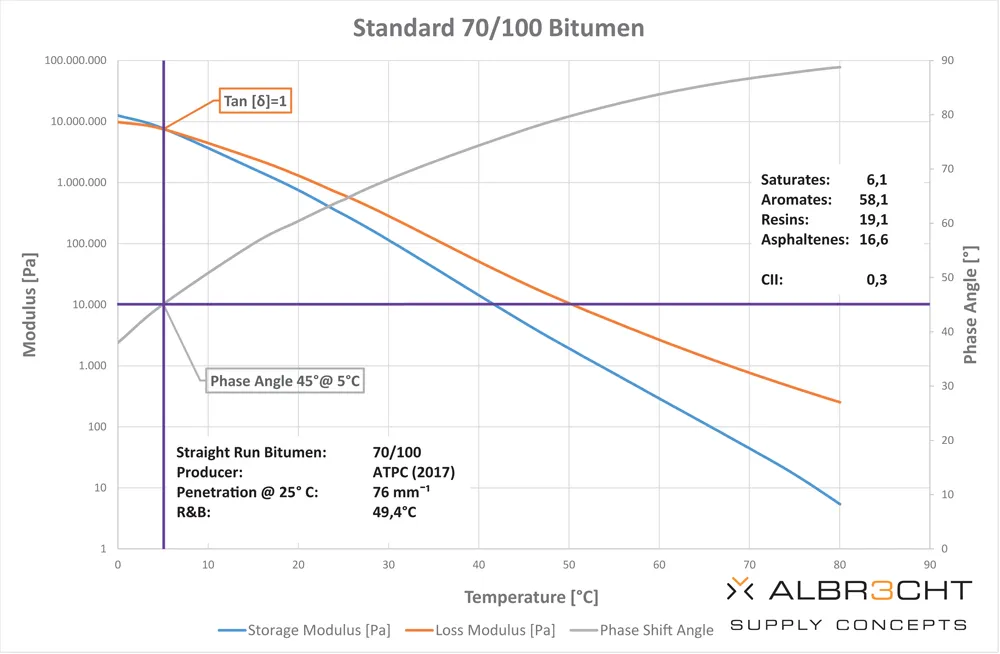

Albrecht Supply Concepts already works with customers to engineer bitumen in order to optimise its performance for various applications. For instance, it might source asphaltenes to help improve the useful temperature interval for pavements and resistance to rutting. A good source of asphaltenes, says Albrecht, is natural asphalt which can be mined from the ground in countries such as Iran, China, Colombia and the US.

“The key is finding the right source of asphaltenes,” said Albrecht. “The chemical composition is important. We need a very pure product with a low ash content.”

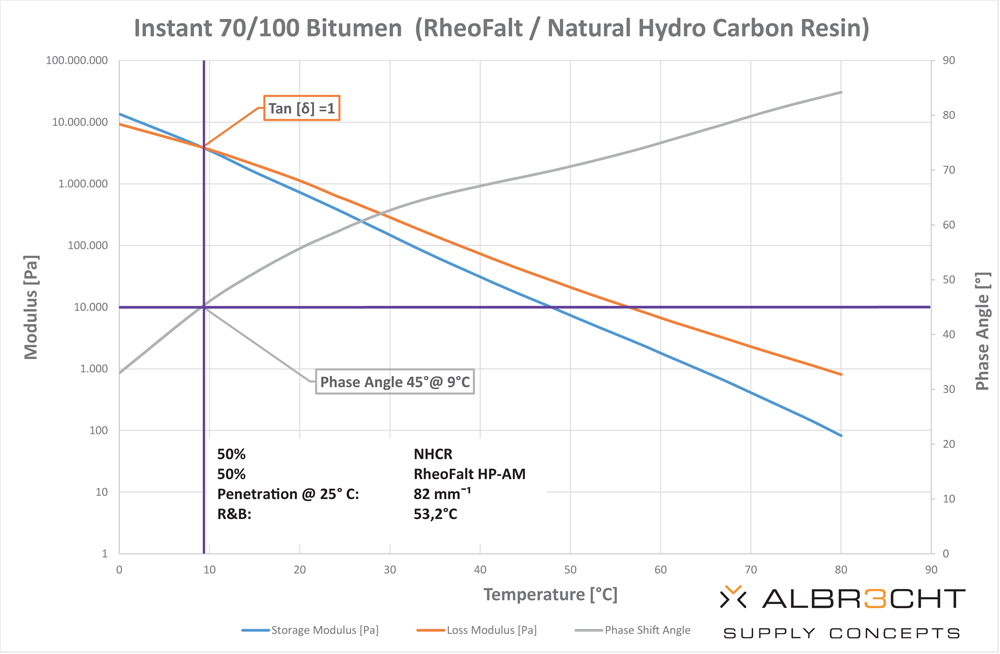

The liquid, maltene phase that goes into Instant Asphalt could come from a number of sources, including by-products from the mineral industry. But Albrecht was interested in finding a natural product and so linked up with Rheophalt which makes a product from the waste cashew nut shells, originally to be used as a rejuvenator.

There are two ways to combine the asphaltene-containing powder and the liquid maltene phase. The first is to mix and heat them to around 185°C for a couple of hours, varying the proportions depending on the grade of bitumen desired. The second way would be to add them straight to the mixer at the asphalt plant:

“We could add the asphaltenes onto the pugmill via the filler line, adding them to the hot stones, with the maltenes added through the bitumen line,” said Albrecht.

The next step in the development of Instant Asphalt will be to set up some live trials to do this. Albrecht is currently looking for partners with whom to run pilot mixing plant projects with.

As well as providing a convenient solution for remote locations, Instant Asphalt is also proving interesting to clients and countries that are pushing to lower the embodied carbon of their buildings and infrastructure. “Some potential customers in Scandinavian countries are very interested,” said Albrecht, who also sees future customers in cities which are looking to be carbon-neutral.

Instant Asphalt has much lower embodied carbon than its refinery-produced cousin. The asphaltene element has a similar carbon footprint to aggregates, lower than products from a refinery. And Instant Asphalt doesn’t have to be kept at high temperatures during transportation, reducing energy demands and lowering the risk of accidents – which almost always occur during transportation.

The toughest conversation to have about Instant Asphalt, said Albrecht, concerns the price:

“Because our system requires completely different and disruptive thinking, it’s difficult to get people off the price,” he said. “If you just compare material costs, Instant Asphalt looks expensive, say €1,500/tonne compared with €400 per tonne for standard asphalt. But if you add in the logistical costs, the heating costs, then the equation starts to look better. And if you go to remote places like Africa or an island, they are almost the same on a cost/tonne basis. Then you have the environmental benefits on top of that.”