An Ammann asphalt plant has been used to supply material for a landmark project in China. The Ammann ABP 320 Universal Asphalt-Mixing Plant played an important role in carrying out preparation work for the high-profile BRICS Summit held recently in China

May 16, 2018

Read time: 4 mins

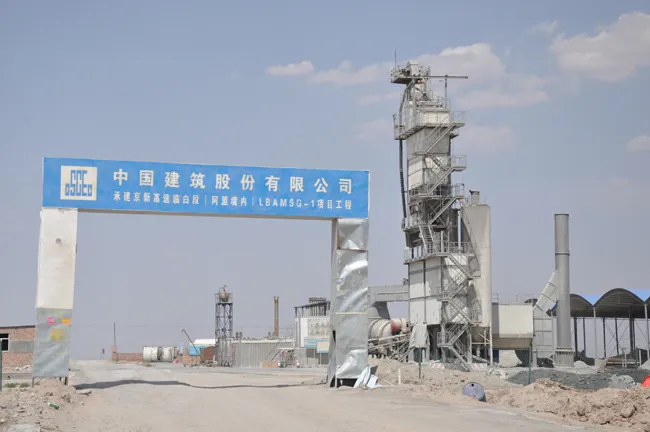

An Ammann asphalt plant has been used to supply material for a landmark project in China. The Ammann ABP 320 Universal Asphalt-Mixing Plant played an important role in carrying out preparation work for the high-profile BRICS Summit held recently in China.

BRICS’ core consists of China, Brazil, Russia, India and South Africa. The heads of the five nations attended, as did other delegates from those and additional countries. Discussion topics included trade, finance, business, agriculture, education, health, science and technology, culture, think tanks and friendship cities.

The recent event was held at Xiamen International Conference Centre in the Chinese port city of Xiamen. China’s president Xi Jinping chaired the summit. President Jacob Zuma of South Africa, president Michel Temer of Brazil, president Vladimir Putin of Russia and prime minister Narendra Modi of India also were present.

Infrastructure improvements were needed in Xiamen given the scope of the event. More than 40km of new roadway and 12km of bike paths were built over a three-month period leading up to the event. The municipality of Xiamen handled the paving, and the6791 Ammann ABP 320 Universal Asphalt-Mixing Plant provided the mix.

The Ammann ABP Universal gained the approval of the US Energy Information Administration (EIA) and is the only asphalt plant in Xiamen to do so. The EIA is an impartial energy information centre. It collects, analyses, and disseminates information to promote sound policymaking. But local asphalt plants developed by other manufacturers could not meet the EIA requirements and had to discontinue operation. Meanwhile the Ammann ABP Universal plant continued to operate due to its environmental features.

“This is the most environmentally friendly plant in China,” Yan Xin, supervisor of Xiamen Municipal Engineering Company, said of the Universal plant. “This is a highly green asphalt plant,” Yan said. “It is equipped with a cold feeder dust collection system and smoke treatment system. There is a dust collection system for hot mix storage silos, a smoke-handling system for bitumen tanks, a heavy-oil smoke-handling system, and so on. “They are all encapsulated inside a big housing,” he added.

A high volume of production was essential too. Paving could only be completed at night, so production time was limited. Yet the plant still had to mix 300,000tonnes in three months.

The timeframe made reliability crucial – as did the lack of other working plants. “If this plant broke down, there was no alternative plant available. Then the BRICS project could not be completed,” Yan said. “But the plant finished the job very well.”

The Ammann ABP Universal Asphalt-Mixing Plant meets the world's strictest requirements for emissions and offers a production output of 240-320tonnes/hour, depending on the material type. The firm says that the unit is a highly versatile mix maker and offers a wide range of equipment and components that enables customisation. A key feature is the plant’s ability to utilise recyclables. The package includes cold feeders, drying drum and filter enclosed to create the appearance of a commercial building. This fully-enclosed design is crucial as it offers reduced sound and dust levels.

There is a growing need for low emission asphalt plants in China, as in many other countries. Chinese regulations on the emissions of industrial equipment such as asphalt plants have been toughened considerably in recent years. These tougher rules have been introduced in a bid to lower pollution levels in urban areas in China as many of its major cities suffer from serious air pollution at present. Both the capital Beijing and the commercial centre Shanghai as well as several of the key industrial cities in China have high levels of atmospheric pollution.

In addition, the Chinese authorities are also keen now to increase levels of recycling in the country. Rules were introduced in recent years on the reuse of asphalt, allowing RAP to be utilised. Asphalt plant manufacturers supplying the Chinese market are seeing a steady increase in interest in equipment capable of using recycled material as a result.

BRICS’ core consists of China, Brazil, Russia, India and South Africa. The heads of the five nations attended, as did other delegates from those and additional countries. Discussion topics included trade, finance, business, agriculture, education, health, science and technology, culture, think tanks and friendship cities.

The recent event was held at Xiamen International Conference Centre in the Chinese port city of Xiamen. China’s president Xi Jinping chaired the summit. President Jacob Zuma of South Africa, president Michel Temer of Brazil, president Vladimir Putin of Russia and prime minister Narendra Modi of India also were present.

Infrastructure improvements were needed in Xiamen given the scope of the event. More than 40km of new roadway and 12km of bike paths were built over a three-month period leading up to the event. The municipality of Xiamen handled the paving, and the

The Ammann ABP Universal gained the approval of the US Energy Information Administration (EIA) and is the only asphalt plant in Xiamen to do so. The EIA is an impartial energy information centre. It collects, analyses, and disseminates information to promote sound policymaking. But local asphalt plants developed by other manufacturers could not meet the EIA requirements and had to discontinue operation. Meanwhile the Ammann ABP Universal plant continued to operate due to its environmental features.

“This is the most environmentally friendly plant in China,” Yan Xin, supervisor of Xiamen Municipal Engineering Company, said of the Universal plant. “This is a highly green asphalt plant,” Yan said. “It is equipped with a cold feeder dust collection system and smoke treatment system. There is a dust collection system for hot mix storage silos, a smoke-handling system for bitumen tanks, a heavy-oil smoke-handling system, and so on. “They are all encapsulated inside a big housing,” he added.

A high volume of production was essential too. Paving could only be completed at night, so production time was limited. Yet the plant still had to mix 300,000tonnes in three months.

The timeframe made reliability crucial – as did the lack of other working plants. “If this plant broke down, there was no alternative plant available. Then the BRICS project could not be completed,” Yan said. “But the plant finished the job very well.”

The Ammann ABP Universal Asphalt-Mixing Plant meets the world's strictest requirements for emissions and offers a production output of 240-320tonnes/hour, depending on the material type. The firm says that the unit is a highly versatile mix maker and offers a wide range of equipment and components that enables customisation. A key feature is the plant’s ability to utilise recyclables. The package includes cold feeders, drying drum and filter enclosed to create the appearance of a commercial building. This fully-enclosed design is crucial as it offers reduced sound and dust levels.

There is a growing need for low emission asphalt plants in China, as in many other countries. Chinese regulations on the emissions of industrial equipment such as asphalt plants have been toughened considerably in recent years. These tougher rules have been introduced in a bid to lower pollution levels in urban areas in China as many of its major cities suffer from serious air pollution at present. Both the capital Beijing and the commercial centre Shanghai as well as several of the key industrial cities in China have high levels of atmospheric pollution.

In addition, the Chinese authorities are also keen now to increase levels of recycling in the country. Rules were introduced in recent years on the reuse of asphalt, allowing RAP to be utilised. Asphalt plant manufacturers supplying the Chinese market are seeing a steady increase in interest in equipment capable of using recycled material as a result.