The company reports that the first fine screening test panels are still in place and performing reliably. NCC Industry's Stone Materials division said that it has long chosen rubber screening media over wire mesh. The choice is crucial in Södra Sandby, where abrasive quartzite produces excessive wear on metal components. Yet despite its preference, the company said that it had struggled to find a long-term rubber solution for fine screening.

A turning point came when

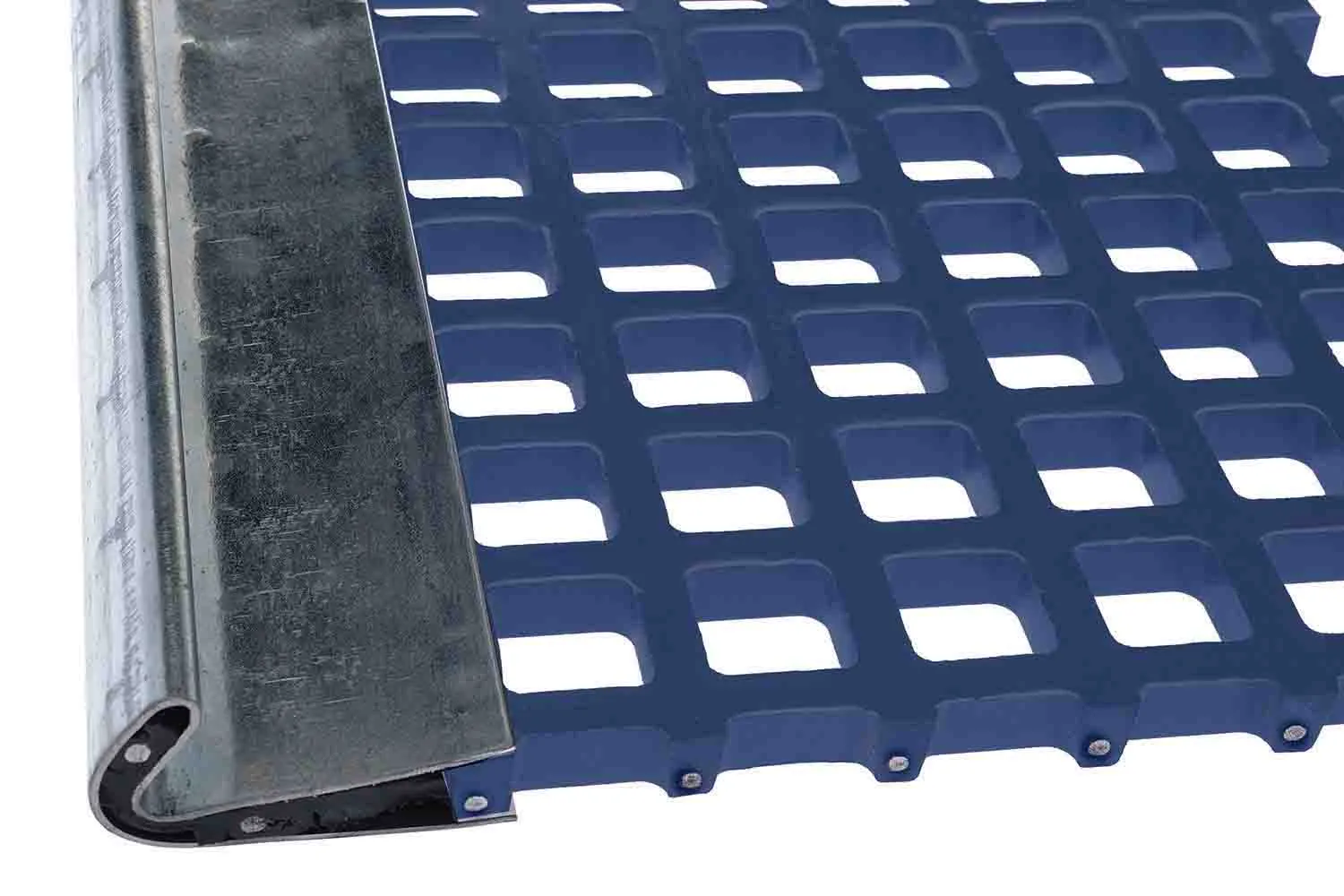

NCC Industry agreed to use the WX6500 on a Mogårdshammar FH C 2172/3 screen, which would receive a feed size of up to 32mm from a Svedala H6800 crusher. Five panels with 26mm holes were delivered as rolls and installed on the upper deck in summer 2016.

“The outer dimensions of this screen are big, but it’s a very tight fit inside,” said Klinte who is also a former service technician. “The WX6500 was thin and very easy to roll out, which makes a difference when there’s little space between the decks.”

Klinte also noted that the panels could be installed with a much higher tension than other rubber media, producing a drumskin-like fit that benefits the screening result. “The material is thin, but you can get a lot rougher with it,” he explained. “Media in standard materials with the same thickness can’t be installed with the same amount of tension.”

A year later

Klinte said that the real revelation, however, came the first time the test installation was inspected. “There was so little wear that you could still see the structural markings from the manufacturing process.” Around 285,000toness have been fed to the WX6500 panels since the start of the test. This far exceeds the 30,000tonnes that would have been achievable with wire mesh and “it’s still going strong”.

Combined with the ease of installation, this durability means further ways to extend the media life. When the panels at the feed end of the deck eventually begin to wear, they can be removed and reinstalled at the far end, where they take less of a beating.

“If you remove a wire mesh panel, you won’t be able to reuse it. It’s sharp, nasty and complicated to get off in one piece. Even if you could, it would be a struggle to get it tight again,” noted Klinte. “WX6500 is light, flexible and perfect to reuse on the screen.

NCC Industry said that Sandvik WX6500 provides highly accurate sizing, ensuring a finished product with the desired maximum dimension of 32mm. “The material is so thin that it really doesn’t plug, so we have no problems with the blinding and pegging that you get with thicker media,” Klinte says.

The problem-free sizing makes the media popular with operators, who also experience 50% less noise compared to wire mesh. “Our plant is indoors to contain the silica dust, so any improvement in noise levels makes a big difference,” he said.

Accuracy is Key

Sandvik’s newest screening media, the WX6500, sorts like steel but lasts like rubber, according to the manufacturer.

The WX6500 screening media has the same accuracy as wire mesh at 2–32mm separations. This means that this marks the first time that customers can choose a rubber media for fine screening.

It offers everything wire mesh media can, but with 10 times the product life and easy delivery as a lightweight roll, said Sandvik. The length and width of the screen deck are all that is needed for a perfect fit.

It takes half the time of mesh media to install and does the same job but with less blinding, less pegging, fewer inspections and a fraction of the media changes. With fewer changes there is far less screen downtime.

The thinness and flexibility of the material prevents the blinding and pegging associated with wire mesh meaning that the desired product comes out first time. Because Sandvik WX6500 blinds and pegs less often, there are fewer media inspections and less time spent on troubleshooting and replacements.

Screening duty: Intermediate and final

Max feed size: 20-70mm

Separation: 2-32mm

Application: Dry

Dewatering: No

Deck design: Cambered

Panel type: Tensioned

Material: Rubber

Aperture: Punched

Fastening: Cross- or length-tensioned