Metso continues to broaden its crushing equipment range with the addition of the latest C-Series jaw crusher.

The C120 is said to offer reliability, crushing efficiency and versatility in both stationary and mobile applications. Described by Metso as safe and easy to use, the C120 is also said to be durable and user-friendly.

March 15, 2012

Read time: 2 mins

The C120 is said to offer reliability, crushing efficiency and versatility in both stationary and mobile applications. Described by Metso as safe and easy to use, the C120 is also said to be durable and user-friendly. Its rugged cast components boost wear life providing high crushing capacity and maximum uptime. The long and aggressively directed stroke and the fixed jaw die, longer than previously seen in this crusher size class, deliver good productivity. The C120 has a large feed opening of 1200 x 870mm coupled with an aggressive cavity cross section, securing a high performance and reduction ratio.

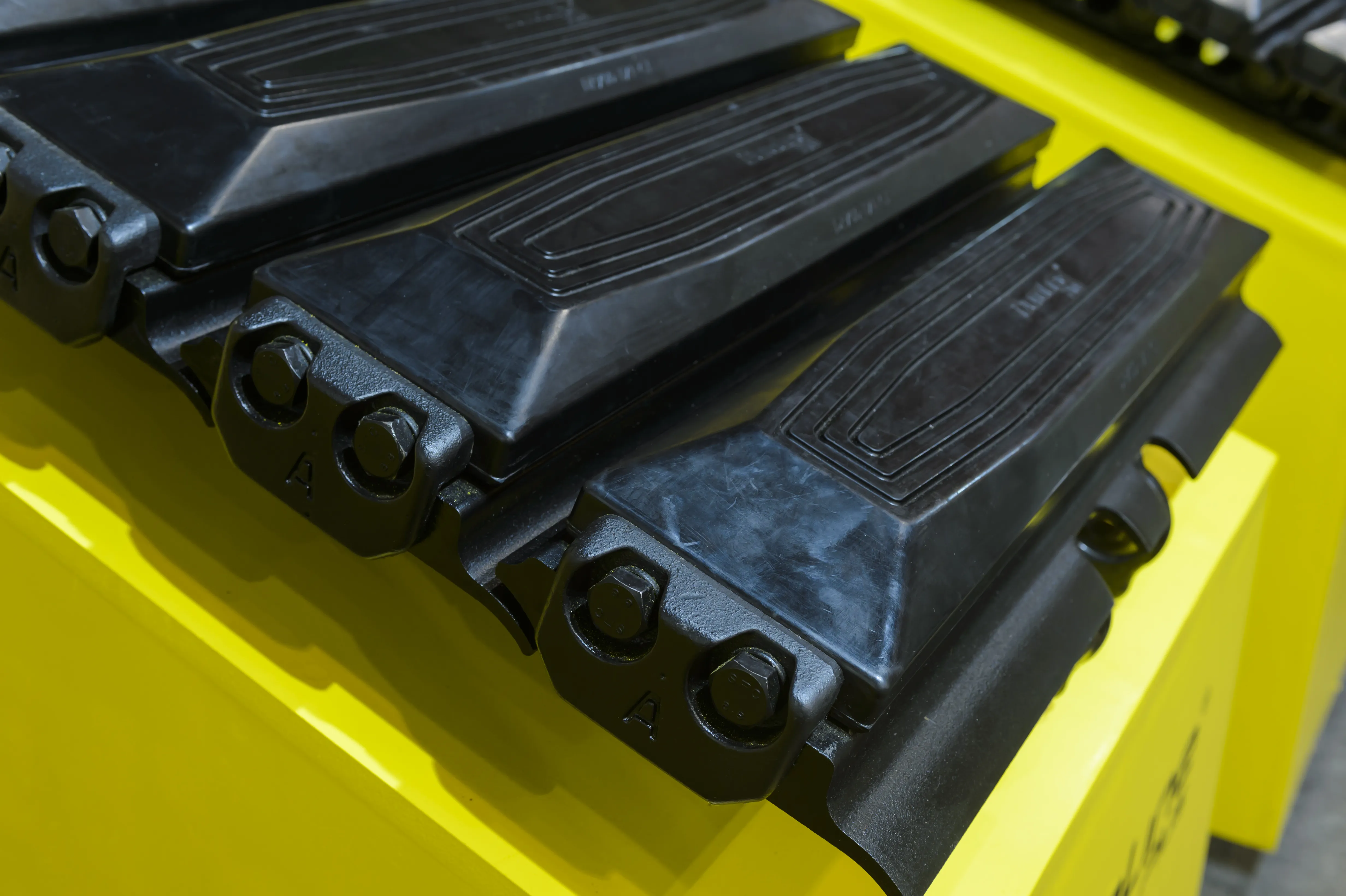

In terms of cavity volume and machine weight, the C120 sits between the existing Metso C116 and C125 models. The C120 is said to be easy to install with a compact design and rubber mounting pads underneath the crusher mounting brackets, while no separate horizontal supports are needed.

The crusher can be mounted in multiple ways to fit onto an existing or a new steel structure and also comes with an optional integrated motor bed and guards. Operators can select either a mechanical or hydraulic setting adjustment system, while for jaw dies, several cavity options are available. Either single- or two-piece jaw dies can be used with the C120.

The new C-Series machine also features optional composite flywheel guards that allow quick and safe access to all service points. The standard delivery includes lifting tools for jaw dies, cheek plates and toggle plate, boosting safety when changing wear parts. The Metso C120 weighs in at 26tonnes without options, has a nominal power of 160kW and closed side settings between 70–200mm.