Work is being done in Engelhartszell in the Upper Austrian district of Schärding, not far from the German border.

Contractor Hemmelmair Frästechnik, from Linz, is making use of the W 100 CFi’s cutting-edge technology, in this case made from steel and carbide.

Wirtgen developed a special solution for the trenching method. A housing containing a narrow cutting wheel fitted with standard W6 picks is mounted behind the folded-in crawler track on the right. With a very large cutting diameter of 1,620mm, it can mill channels up to 600mm deep and 300mm wide. The rotary milling motion conveys the milled material upwards, where it is discharged via a baffle plate and chute.

The deep milling unit is controlled from the traditional control panel of the W 100 CFi.

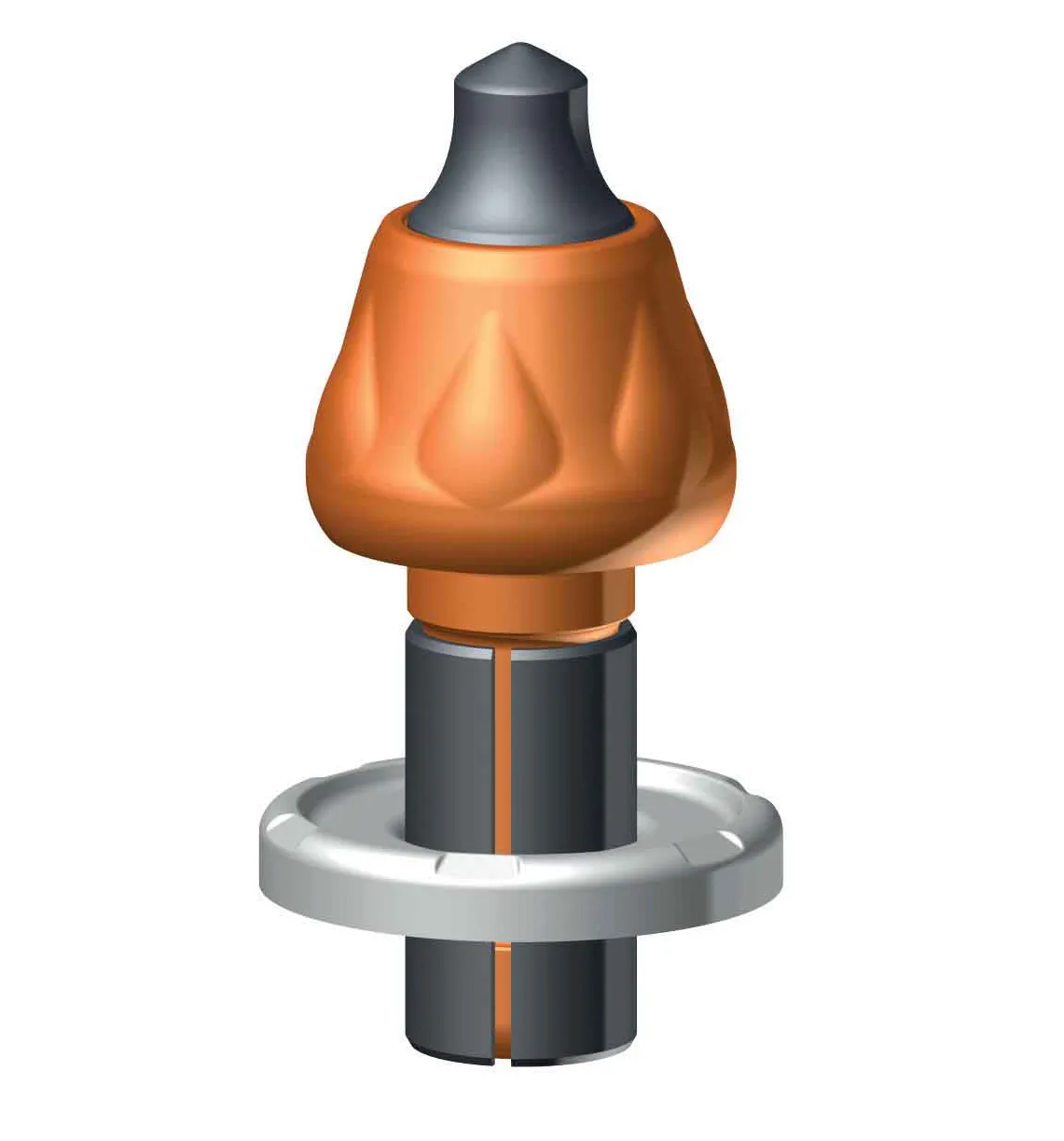

Wirtgen’s Flexible Cutter System has milling drums with a variety of tool spacings or working widths. The drum can be replaced in 30-90 minutes depending on the machine – converting the cold milling machine from a standard to a fine milling machine, for instance.

Removing ruts from a country road, preparing a carriageway for a thin overlay using a fine milling drum or removing coatings on asphalt or concrete surfaces with a micro fine milling drum – all of these tasks can be handled with the same cold milling machine. The range of FCS milling drums is large, opening up a vast array of applications for cold milling machines.