Designed for recycling applications, the Sandvik QA331 is a three-way split screener developed from the successful QA330. The machine offers greater screening capacity than its predecessor but retains the durable construction and suits applications in recycling and contracting.

February 15, 2012

Read time: 2 mins

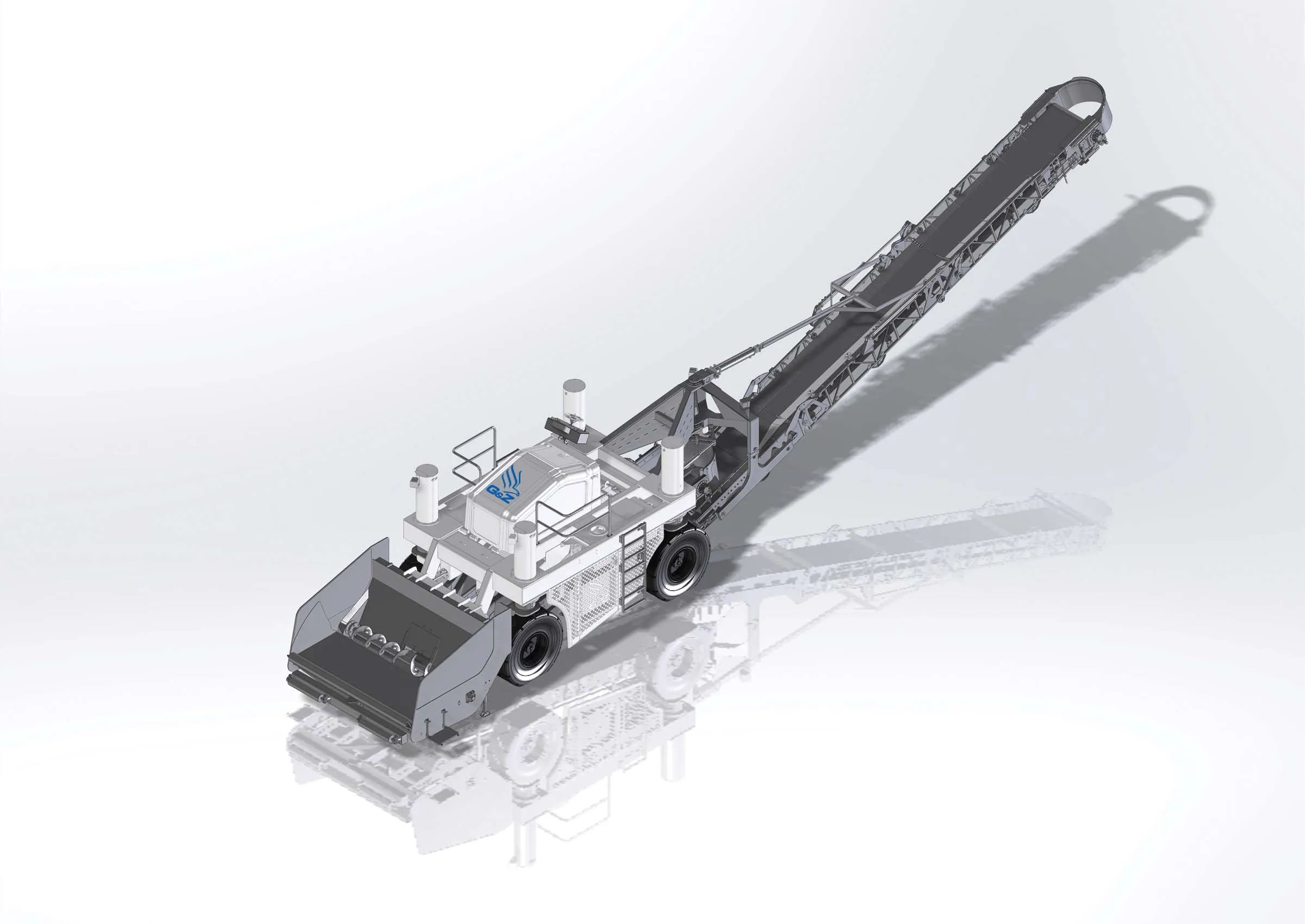

Designed for recycling applications, the 325 Sandvik QA331 is a three-way split screener developed from the successful QA330. The machine offers greater screening capacity than its predecessor but retains the durable construction and suits applications in recycling and contracting. Increased productivity and accurate screening are said to be key performance features. The 4.27m x 1.52m, two bearing screen box features an increased 6° screening angle built into its bottom deck. This feature, coupled with the larger screening surface area, and increased throw on the screen box, boosts operating efficiency and capacity. The machine has a 7m3 hopper and a radio controlled reject grid and can be used for working at the quarry face, inner city development or recycling centre. It has a heavy-duty chassis that ensures durability in tough operating conditions, while it has been designed to minimise fuel consumption and operating costs.

Other features of the QA331 include its novel folding access walkway fitted as standard around the screen box, which provides the operator with access for maintenance. The main conveyor has a 1.05m, heavy duty belt, runs on tracks that are 500mm wide to cope with varying ground conditions and the machine can be guided into position using a remote control box for ease of mobility.

Other features of the QA331 include its novel folding access walkway fitted as standard around the screen box, which provides the operator with access for maintenance. The main conveyor has a 1.05m, heavy duty belt, runs on tracks that are 500mm wide to cope with varying ground conditions and the machine can be guided into position using a remote control box for ease of mobility.