FAE says that its dedicated soil stabiliser is now well-accepted and can work to depths down to 500mm. Because the unit is towed by large tractors, it is suitable for smaller and more compact sites where self-powered stabilisers would be difficult to use.

As the units are towed by large tractors, the company also distributes the machines through a number of tractor dealers, according to Giorgio Carera, chief executive of FAE in North America. “That’s the kind of distribution we use.”

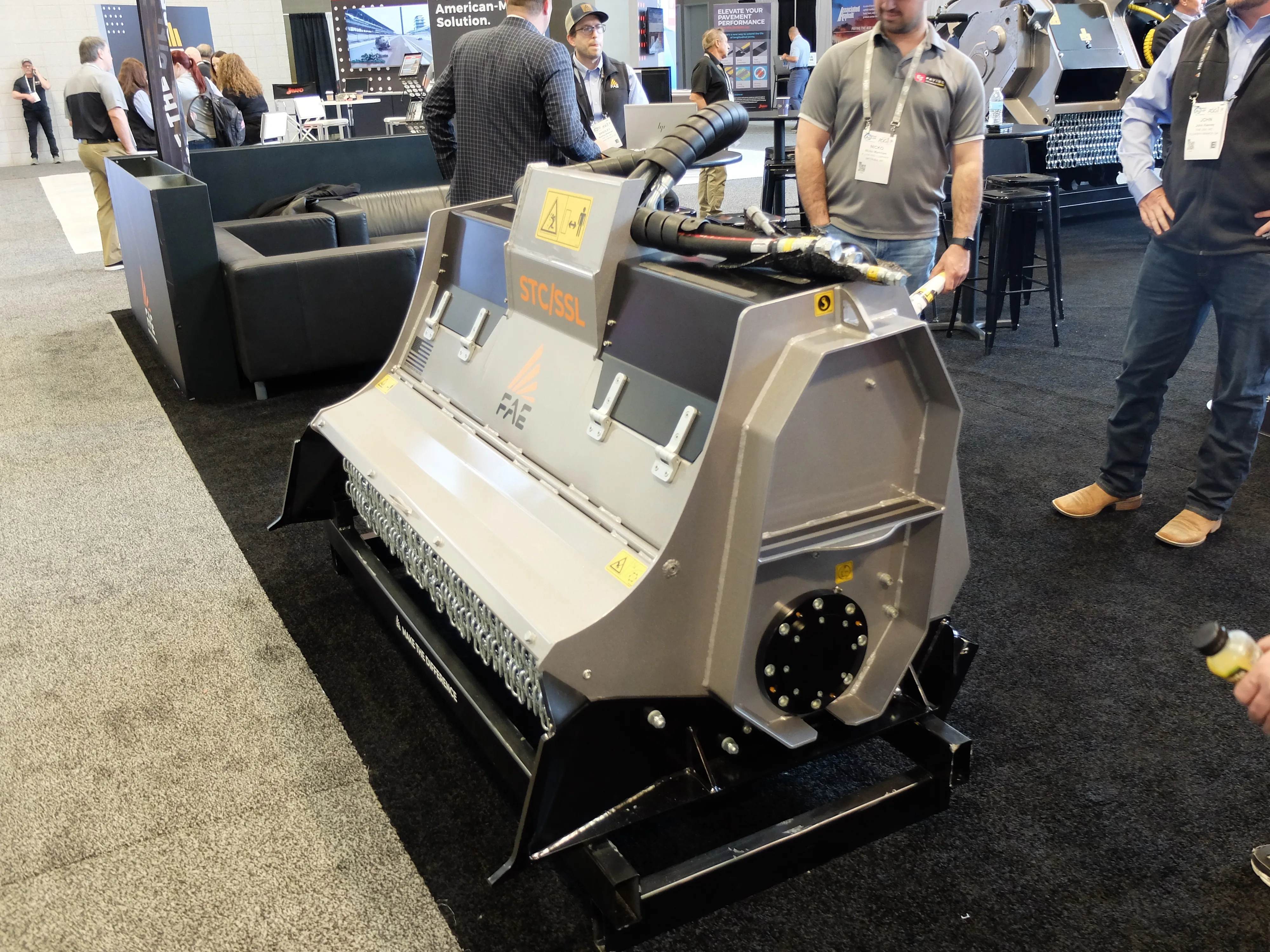

FAE also recently introduced a rock crusher for use with a skid steer loader. The unit has a hydraulic door at the rear to let material out once it has been processed while the rotor spins upwards towards the front. Material is thrown against a Hardox bar, with this action then breaking up the feed into smaller sizes.

Users can set the machine for producing different material sizes by adjusting the bar. Users can turn the Hardox bar around when it wears down, which doubles the working life of the component. The firm believes that this unit offers considerable potential and is the only one on the market, according to Carera.

The new CBA30 asphalt granulator from Simex offer a capacity of 0.8m³ while the more powerful new CBA40 unit offers a capacity of 1m³.

The asphalt granulator buckets are designed for the reduction of asphalt slabs or other aggregates on site. The units feature drums powered by hydrostatic drives, while interchangeable teeth allow a range of product grades to be handled.

The configuration of the rear-grille determines the size of output material and this is available in different setup. Users can set the units to deliver a quality RAP product to meet requirements. An automatic system also changes drum rotation direction in case of blocking, which helps to optimise productivity and reduce downtime.

Meanwhile, the latest crushing and screening plants from CAMS are designed to operate in hybrid mode (diesel/electric) or fully electric. The company says that this allows versatility as well as lowering energy consumption.

In addition, the company has developed technology to significantly reduce noise and dust generated by the mills during the processing stage.

The company now offers seven product ranges and 22 models, which can handle an array of product types and work in different applications, while delivering efficient processing of recycled materials.