Lintec’s HRC hot recycling system allows up to 60% RAP being used in each batch, providing significant environmental benefits as well as major cost savings. And since this plant was commissioned it has produced over 2 million tonnes of asphalt, with a high percentage of RAP use. After reaching this milestone, it has now finished supporting construction of the S244 regional expressway and other rehabilitation projects in China’s Anhui province. The plant installation commenced in February 2016 on a site in Lu’An city. The plant then began operations in June 2017, providing hot mix asphalt for the 23km Huoqiu Garden to Xuji interchange section of the S244. The plant produced approximately 150,000tonnes of mix for the 03 section of the highway, after which the project was completed in 2022.

Having concluded work on the expressway, the equipment has since been used to carry out asphalt pavement repair and maintenance projects on other expressways in Anhui province. Total production for the plant passed the 2 million tonne mark and continues to climb. The use of the HRC system in the plant has allowed the contractor to use an average of 40% RAP in the mix. The Lintec plant features a 320tonnes/hour capacity and paired with the HRC system, has allowed the efficient integration of RAP. According to Lintec, its HRC attachment can be retrofitted into any of the firm’s asphalt plants to allow the use of RAP from milling waste or road surface material excavated during repair works. This helps lower the transport and production costs of asphalt, while reducing the need for fresh bitumen and aggregates.

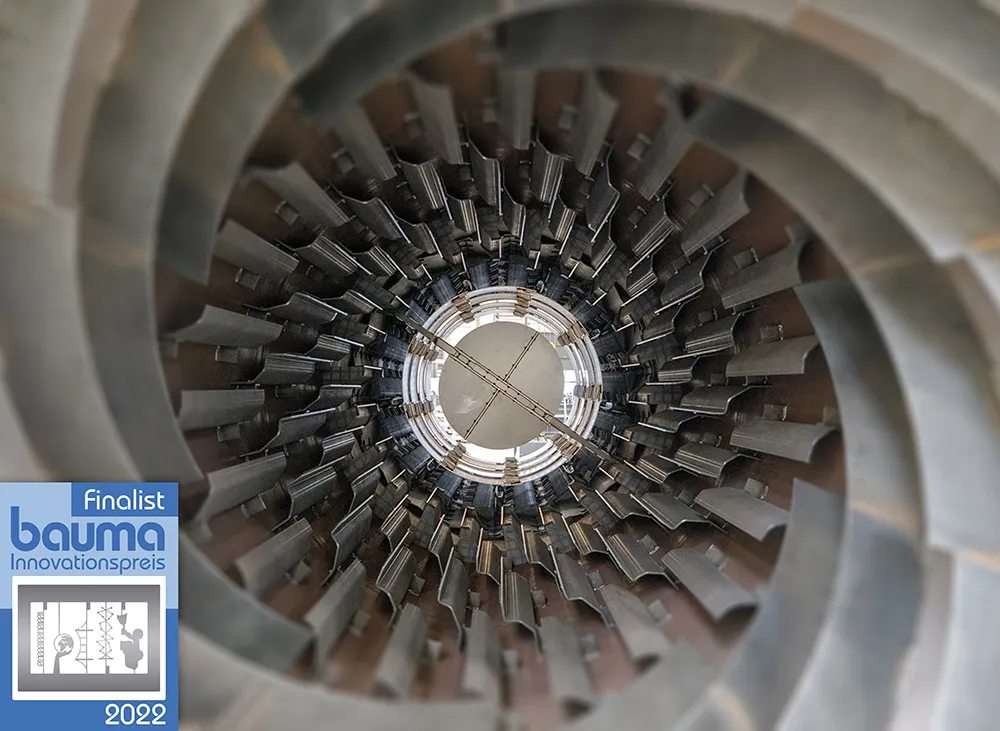

RAP materials are first pulverised in an asphalt recycling granulator and then processed and screened into the required sizes. They are then heated inside the HRC’s parallel drum and kept at the optimum temperature of 140-150°C before being fed into the RAP buffer silo before weighing. By being kept completely separate from the virgin aggregates until mixing begins, the desired amount of RAP can be chosen for each batch. The RAP then mixes with the separately weighed and screened virgin aggregates to produce a precisely controlled batch of hot mix asphalt. The hot recycling system offers several other environmental advantages besides reducing the need for quarrying raw materials.