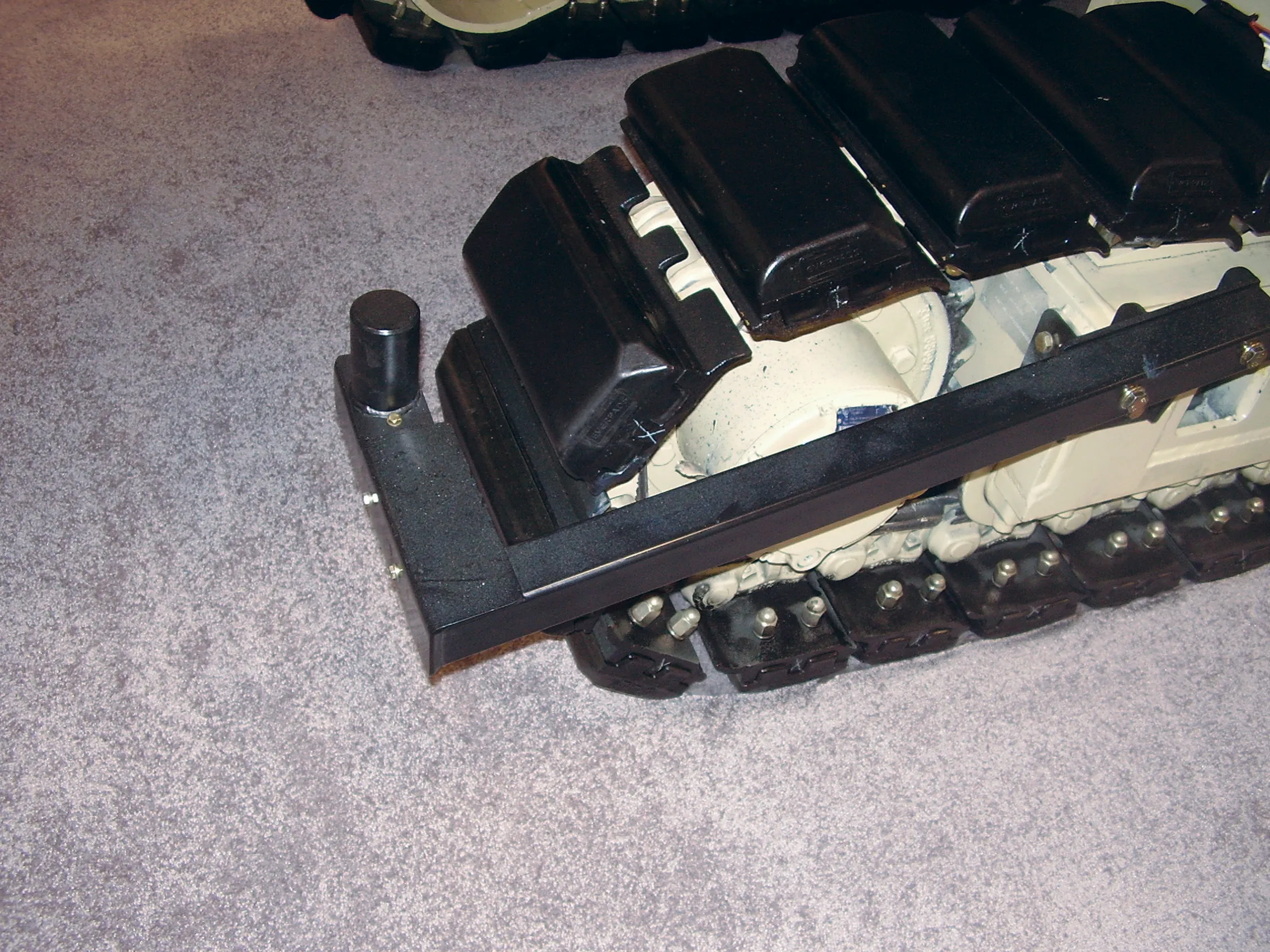

UK road maintenance contractor Jet Plant has now added another milling machine to its fleet, a Wirtgen W100F model. This is the 50th Wirtgen mill the firm has purchased in its 19 years of trading and the company currently runs 23 of these machines in its fleet, alongside its tipper trucks and road sweepers. The company also recently acquired milling specialist Tetlaw, based in Newton Abbot, Devon, extending the company's operations to cover the whole of the UK, making it a major player in the country. The f

July 19, 2012

Read time: 2 mins

RSSUK road maintenance contractor 6253 Jet Plant has now added another milling machine to its fleet, a 2395 Wirtgen W100F model. This is the 50th Wirtgen mill the firm has purchased in its 19 years of trading and the company currently runs 23 of these machines in its fleet, alongside its tipper trucks and road sweepers. The company also recently acquired milling specialist Tetlaw, based in Newton Abbot, Devon, extending the company's operations to cover the whole of the UK, making it a major player in the country.

The full line-up of cold milling machines includes two 350mm, six 500mm planers and three 2m units, while the company's latest addition brings the number of 1m tracked machines to five. The company also operates seven 1m wheeled planers, also Wirtgens.

"We get anything between 60% and 90% utilisation from the planer fleet, depending on the time of year," said Sean Witheford, Jet's managing director, "so it's important that the machines are reliable. We have that confidence. We don't tend to consider replacing our machines for four years or more, when they're still in excellent condition."

Sean took over running of the company seven years ago, from his father Stuart, while brothers Brian and Scott head up the group's Henson Plant Hire and Scott Tippers earthworks operations respectively. Jet Plant Hire is a family-run business, established in 1989, specialising in cold milling machinery and a range of associated ancillary equipment, such as sweepers and tippers.

The full line-up of cold milling machines includes two 350mm, six 500mm planers and three 2m units, while the company's latest addition brings the number of 1m tracked machines to five. The company also operates seven 1m wheeled planers, also Wirtgens.

"We get anything between 60% and 90% utilisation from the planer fleet, depending on the time of year," said Sean Witheford, Jet's managing director, "so it's important that the machines are reliable. We have that confidence. We don't tend to consider replacing our machines for four years or more, when they're still in excellent condition."

Sean took over running of the company seven years ago, from his father Stuart, while brothers Brian and Scott head up the group's Henson Plant Hire and Scott Tippers earthworks operations respectively. Jet Plant Hire is a family-run business, established in 1989, specialising in cold milling machinery and a range of associated ancillary equipment, such as sweepers and tippers.