A

Its old central street are, like many similarly picturesque towns, simply too narrow for a tracked planer. But the contractor

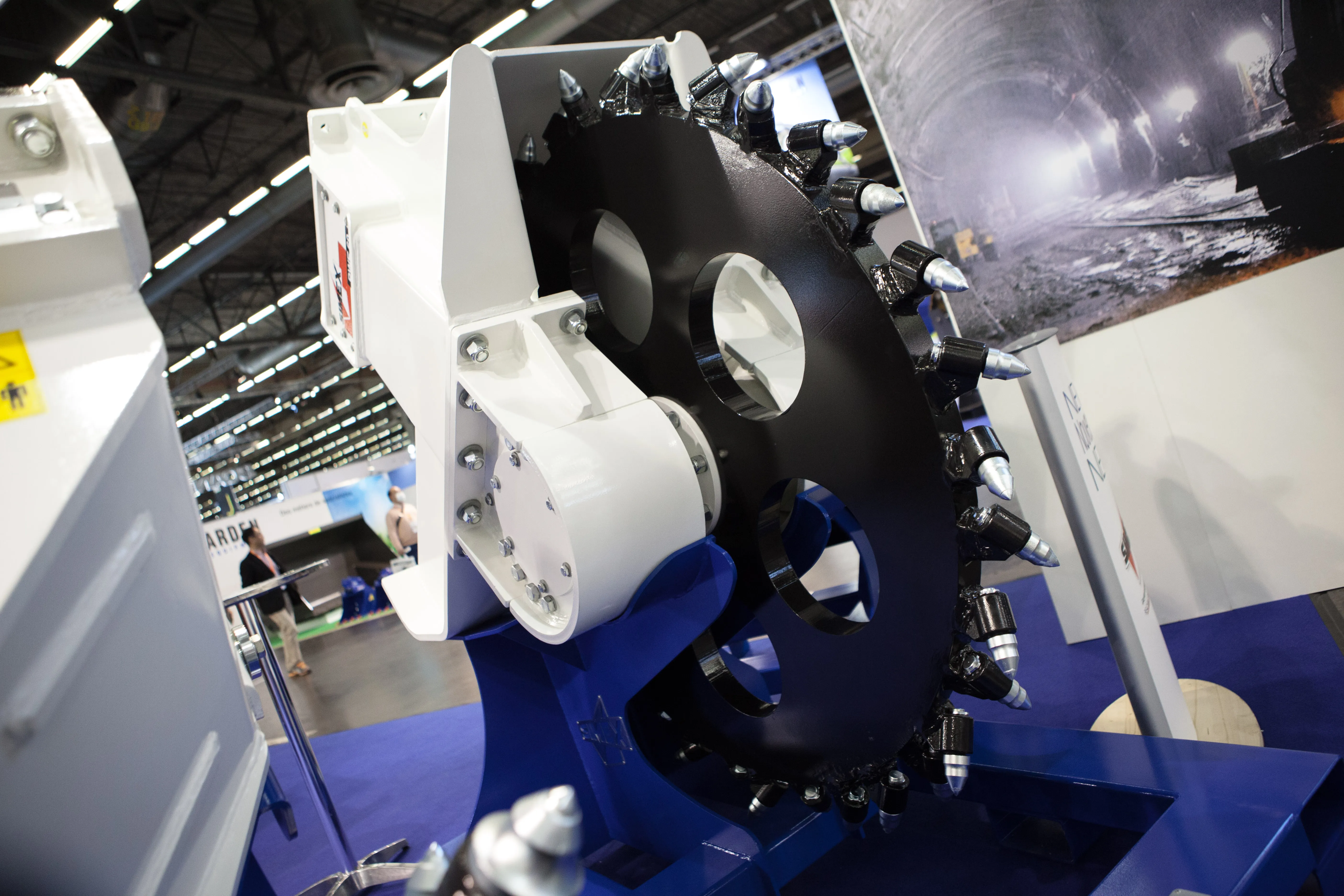

Among the many machines and attachments in the contractor's fleet is a Simex PL 5020 self-levelling planer, a milling machine that goes where larger machines can’t. The PL 5020 proved a great solution because it could operate productively and precisely when working right up against manholes, vehicle entrances and sloped surfaces.

Like all pavers of Simex’s PL series, the PL 5020 purchased by Varesco is fitted with pistons in direct drive with the milling drum. This leads to high efficiency and low overheating.

The self-levelling system allows the attachment to operate at a constant milling depth in any condition, regardless of the ground contour and the position of the attachment with respect to the prime mover. The lateral slides of the planer, in fact, automatically align to the milling surface.

Problems related to poor visibility of the work area are non-existent for the operator because the depth obtained is exactly as predetermined, thanks to the self-levelling feature.

The slides move independently of each other, perfectly following the work surface whether to the right or left. The independent depth adjustment on the right and left sides combined with the self-levelling system achieves perfect surfaces with side-by-side passes.