The firm’s dedicated soil stabiliser is now well-accepted and can work to depths down to 500mm. Because the unit is towed, it is suitable for smaller and more compact sites where self-powered stabilisers would not be suitable.

As the stabilisers are towed by large tractors, the company also distributes the units through a number of tractor dealers. Giorgio Carera, CEO of FAE in North America said, “That’s the kind of distribution we utilise.”

The machines are said to offer high utilisation, as well as being highly productive.

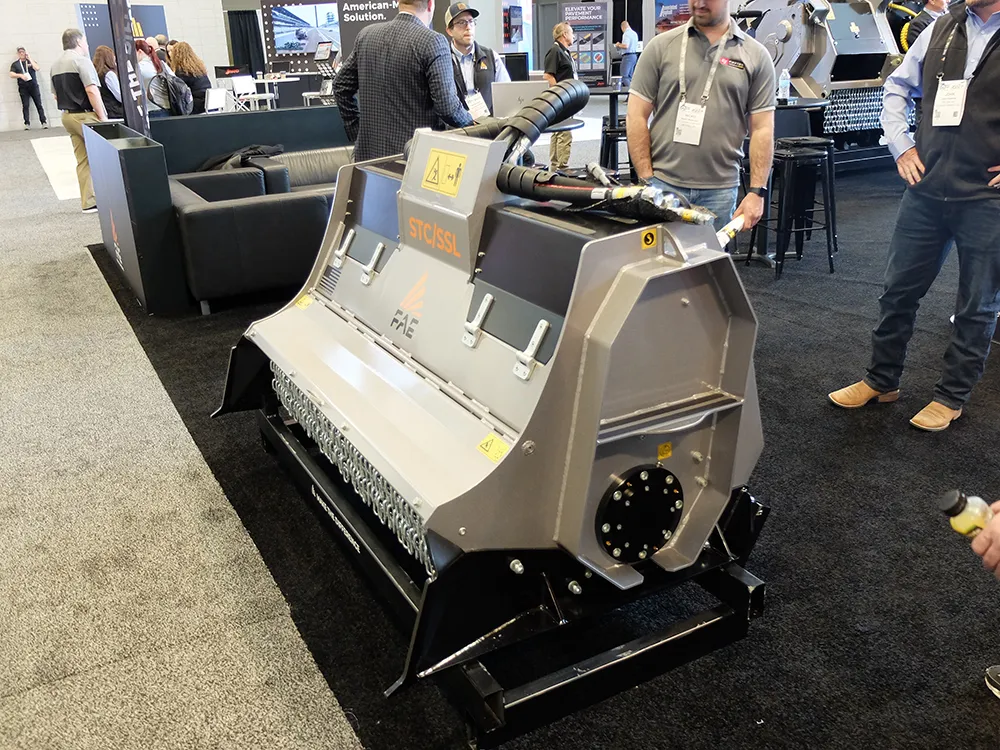

New products are coming to market too and the company now offers a rock crusher unit for use with a skid steer loader. The unit has a hydraulic door at the rear to let material out once it has been processed while the rotor spins upwards towards the front. Material is thrown against a Hardox bar, with this action then breaking up the feed into smaller sizes. Users can set the machine for producing different material sizes by adjusting the bar. The Hardox bar can be turned around when it wears, which doubles the working life of the component. The firm believes that this unit offers considerable potential and Carera commented, “It’s the only one on the market.”