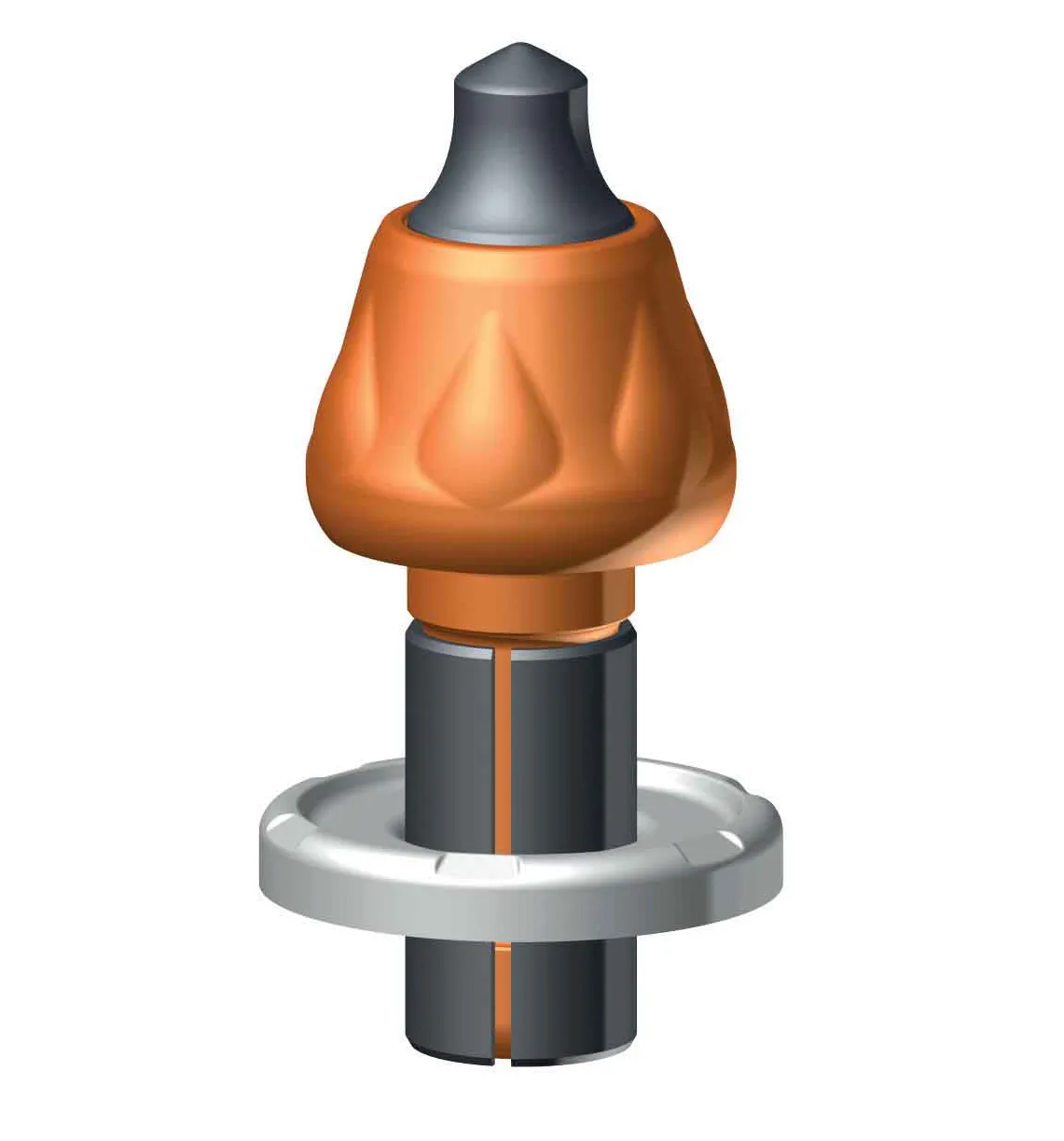

Roadtec is improving its line of cold planer cutter drums to provide a better milling pattern and a longer tool and base life. The firm has reworked the drum end ring configuration for better match-cutting and to extend tool life. The impact angle of the tools on the drum has been optimise and this will lengthen the life of the consumable bit. The lacing pattern has been adjusted and this allows for a better texture on the milled surface as well as a more balanced impact when the tools strike the cutting ar

February 28, 2012

Read time: 2 mins

Roadtec's Jeff Rule explained, "With the redesign we've eliminated the wear problem some of our customers were experiencing with their drums at the end rings. If the users keep up their cutter tools and holders properly, they will see a significant increase in the longevity of the holder and base block out of these drums."