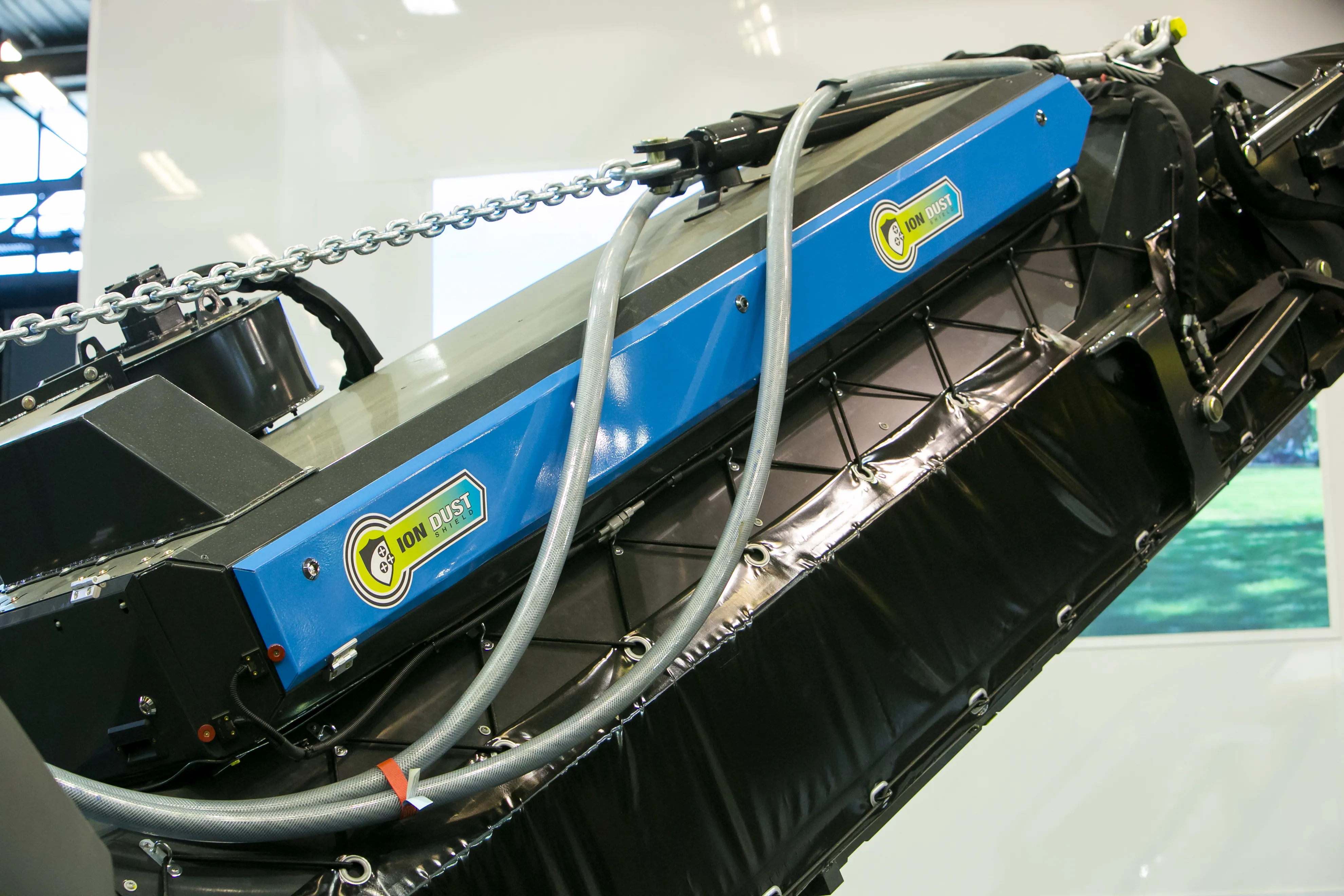

He said that while existing dust control systems remove dust from the working area around the operator, many then exhaust the dust forward of the machine away from the crew. However this new package is said to clean up the working area around the milling machine, suiting it in particular to use in urban areas.

The package works by positively charging the very fine dust particles, which then, “…clump together and form into much larger particles,” as Stringham explained. These much larger particles can then be collected easily and removed. The system operates without filters so needs minimal maintenance and can remove 80-85% of the dust emissions from the milling process.

The system is being fitted to the BM 1000-35 milling machine from BOMAG first, as Stringham commented that this 1m class unit is popular for urban duties where minimising dust is of greater importance. However, he added that the package will also be offered on larger machines such as the 2m class units from BOMAG in the future.