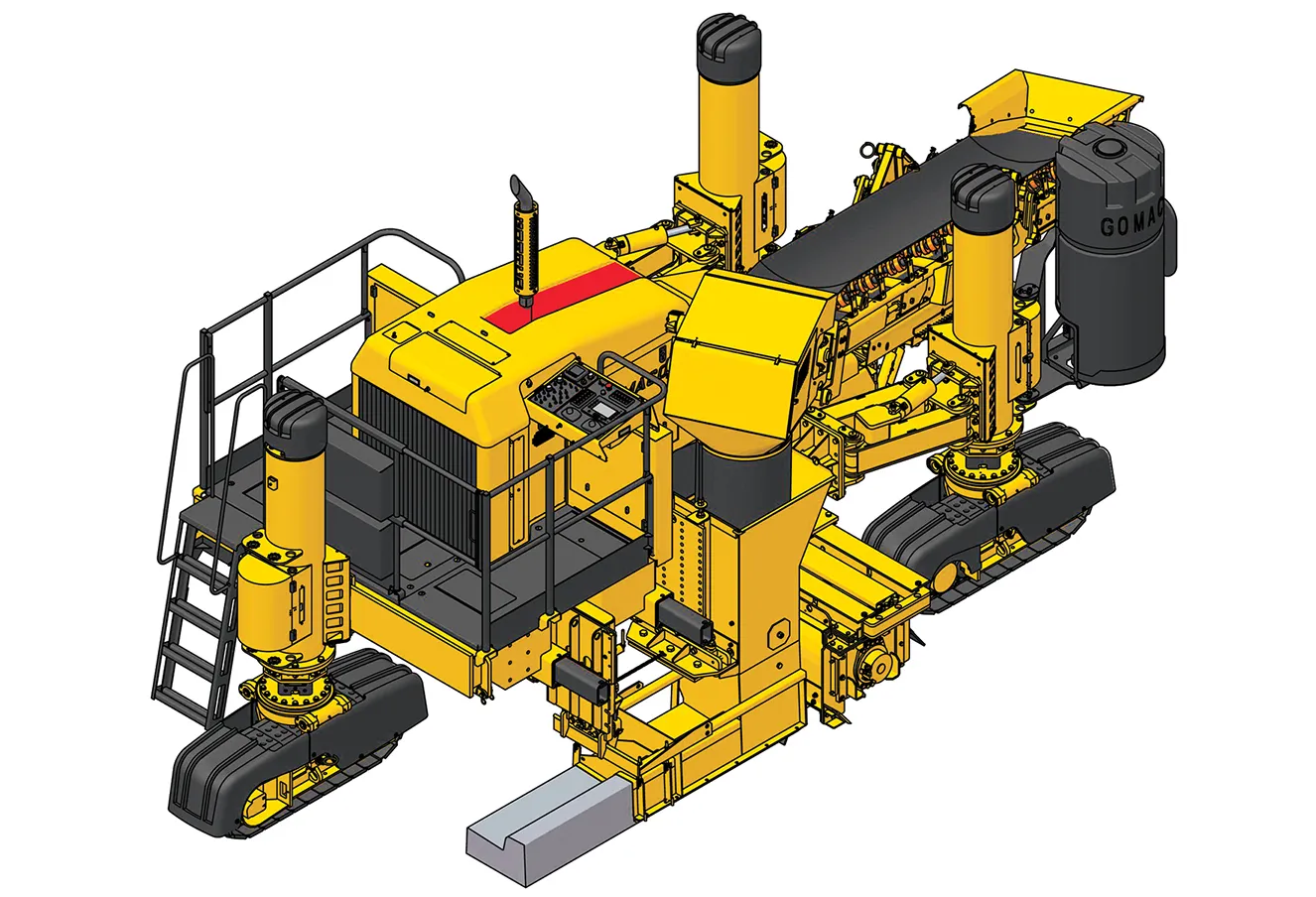

The firm says that its PM300 Series suits use in small-to-medium job sites where compact dimensions, optimum manoeuvrability and high production capabilities are required. The PM300 Series can be configured with one of three drum widths and a choice of wheel or track undercarriage. An articulating right leg can be positioned outboard to provide additional stability during demanding cuts or positioned inboard for true flush cutting on the right side.

The PM300 Series features sophisticated controls and system integration, and offers a full range of options and configurations to further increase versatility. The Cat PM300 Series models are equipped with 242kW Cat C9 ACERT diesels, matched with an optimised cooling.

The PM310 offers a 1m rotor and chamber; the PM312 offers a 1.2m rotor and chamber; and the PM313 offers a 1.3m rotor and chamber. A novel feature is that the rotor system is extended inward towards the chassis as opposed to extending outside the frame. This allows the three models to possess the same overall machine width despite different width of cut. This feature also allows the swinging leg on the right side to position in-line with the rotor for high production cuts or inboard in front of the rotor for flush cutting, as well as easing loading and transport.

The cutting chamber and rotor are positioned at the back of the machine, allowing tight turns while cutting around obstacles. The operator station is mounted above the cutting chamber to optimise visibility.

The PM300 Series models are available with tracks or wheels, while a dust reduction system is standard in countries that require it (optional in all other regions). It can be uprated with an additional water spray system.