A durable and cost-efficient method of road rehabilitation has been carried out on a local road in Germany using an innovative cold recycling technology.

February 6, 2012

Read time: 3 mins

A durable and cost-efficient method of road rehabilitation has been carried out on a local road in Germany using an innovative cold recycling technology.

The method was employed in the German district of Rotenburg/Wümme, Lower Saxony, to repair a local road while keeping costs in check. Its aim was to provide a better surface quality than with conventional systems and to recycle material from the existing road.

Large parts of the district are made up of coastal heathland with sand deposits and extensive woods and moors, this means that the roads often have sub-surfaces with low bearing capacities and are prone to major deformation, unevenness, edge damage and cracking.

Repair budget limits rule out completely rebuilding roads, so the local authorities have relied on re-using sub-base layers, new asphalt surfaces or localised patching. The wear life and quality of these repairs was not meeting expectations so the Office for Water Management and Road Construction for the district opted to try the innovative recycling system to repair the K101 district road linking Mintenburg with Fahrendorf.

Good results had already been achieved with this method in 2005 and 2007, using cold recycling with foamed bitumen.

The main contract was awarded to specialist company Kutter, while a number of other companies were involved in the work.

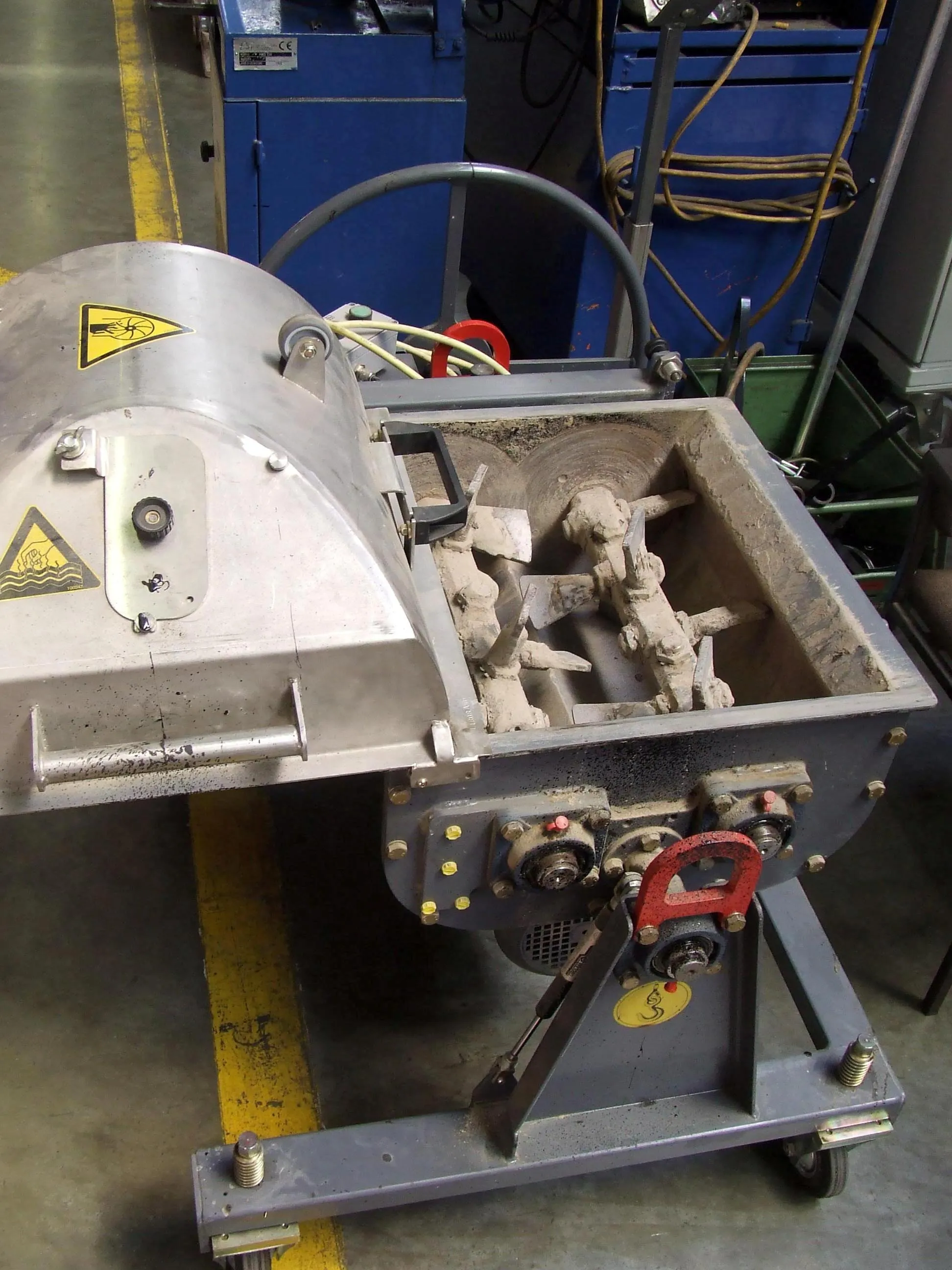

A planer was employed to mill the existing surface to a depth of 300mm in sections. The pulverised asphalt was graded, levelling settlement in the old road, and after pre-compacting this layer with a 10tonne single drum roller, the coarse 150mm upper layer was sized in a crusher to reduce maximum aggregate to around 32mm. The 150mm thick layer was then cold recycled using a foamed bitumen additive.

The grading and quantity of additional material was tested and the additive percentages of reaction water and mixing water were calculated. Specialist stabilisers or recyclers featuring the appropriate water and bitumen additive equipment are required for this type of work to produce the base layer.

High mix quality, uniform working depth and water and binder dosage accuracy are key factors in the quality of the new layer. For this project a172 Bomag MPH125 stabiliser played a key role.

Foamed bitumen and water were added to produce the optimum water content in the 150mm recycled layer. The recycler was hooked up to bitumen and water tankers. Dosage criteria such as the density of the mixed material and the specified bitumen percentage, as well as the proportions of reaction and mixing water, were entered and registered in the machine's data terminal, an electronic dosing controller that ensured the flow rate was continuously adjusted to the targets.

The cold recycled layer was continuously monitored, after which a 10tonne single drum roller was used for pre-compaction, followed by a grader and another 10tonne roller. Finally a surface course with hot binder was laid and two chipping layers applied, using conventional paving and compaction techniques and equipment.

The quality of the finished repair met the requirements of the authorities and the method will now be used more widely in the area. The costs were comparable to conventional replacement of the sub-base layer and a new surface layer, while a higher quality was achieved: eliminating the transport of material to and from the site brought added cost savings.

The method was employed in the German district of Rotenburg/Wümme, Lower Saxony, to repair a local road while keeping costs in check. Its aim was to provide a better surface quality than with conventional systems and to recycle material from the existing road.

Large parts of the district are made up of coastal heathland with sand deposits and extensive woods and moors, this means that the roads often have sub-surfaces with low bearing capacities and are prone to major deformation, unevenness, edge damage and cracking.

Repair budget limits rule out completely rebuilding roads, so the local authorities have relied on re-using sub-base layers, new asphalt surfaces or localised patching. The wear life and quality of these repairs was not meeting expectations so the Office for Water Management and Road Construction for the district opted to try the innovative recycling system to repair the K101 district road linking Mintenburg with Fahrendorf.

Good results had already been achieved with this method in 2005 and 2007, using cold recycling with foamed bitumen.

The main contract was awarded to specialist company Kutter, while a number of other companies were involved in the work.

A planer was employed to mill the existing surface to a depth of 300mm in sections. The pulverised asphalt was graded, levelling settlement in the old road, and after pre-compacting this layer with a 10tonne single drum roller, the coarse 150mm upper layer was sized in a crusher to reduce maximum aggregate to around 32mm. The 150mm thick layer was then cold recycled using a foamed bitumen additive.

The grading and quantity of additional material was tested and the additive percentages of reaction water and mixing water were calculated. Specialist stabilisers or recyclers featuring the appropriate water and bitumen additive equipment are required for this type of work to produce the base layer.

High mix quality, uniform working depth and water and binder dosage accuracy are key factors in the quality of the new layer. For this project a

Foamed bitumen and water were added to produce the optimum water content in the 150mm recycled layer. The recycler was hooked up to bitumen and water tankers. Dosage criteria such as the density of the mixed material and the specified bitumen percentage, as well as the proportions of reaction and mixing water, were entered and registered in the machine's data terminal, an electronic dosing controller that ensured the flow rate was continuously adjusted to the targets.

The cold recycled layer was continuously monitored, after which a 10tonne single drum roller was used for pre-compaction, followed by a grader and another 10tonne roller. Finally a surface course with hot binder was laid and two chipping layers applied, using conventional paving and compaction techniques and equipment.

The quality of the finished repair met the requirements of the authorities and the method will now be used more widely in the area. The costs were comparable to conventional replacement of the sub-base layer and a new surface layer, while a higher quality was achieved: eliminating the transport of material to and from the site brought added cost savings.