In what it says is a "a world first," Swedish specialist company Aquajet Systems has introduced a new diesel/electric-powered hybrid hydrodemolition robot offering a wide range of new features, including pollution-free operation in enclosed areas in electric-mode.

February 27, 2012

Read time: 2 mins

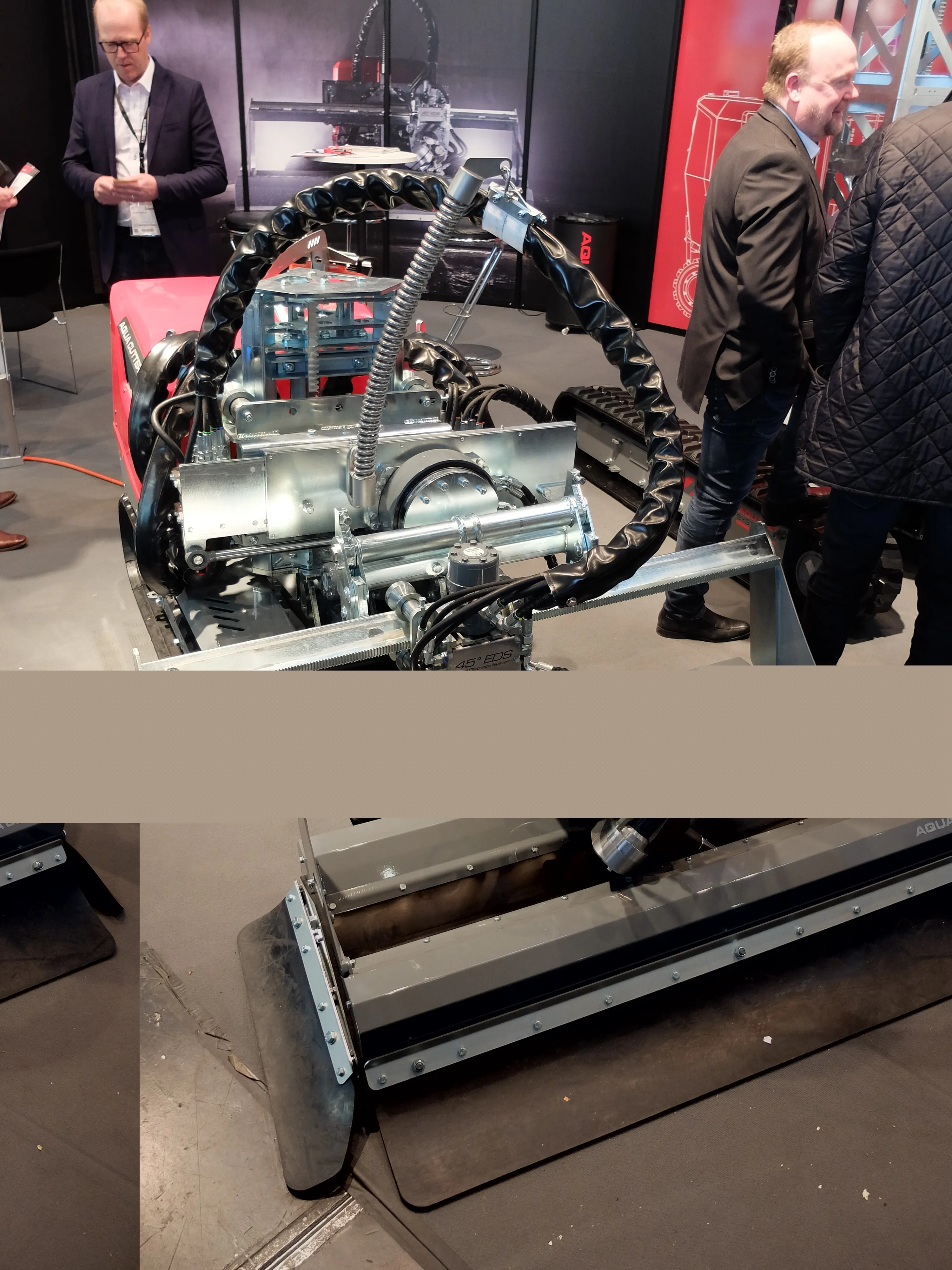

In what it says is a "a world first," Swedish specialist company 2784 Aquajet Systems has introduced a new diesel/electric-powered hybrid hydrodemolition robot offering a wide range of new features, including pollution-free operation in enclosed areas in electric-mode.

The hybrid systems power pack is powered by a 15 kW engine or a 15 kW electric motor, and simple 'switchover' operation ensures easy change to diesel power.

Featuring an optional extended mast height of up to 9m, the new robot offers larger, adjustable tracks to provide a variable width of between 1.5-2m for increased stability if required.

The hybrid model also incorporates a new type of steering drive to turn and twist the unit's powerhead at the increased heights to provide improved precision.

Aquajet has also developed a multi-axis system allowing the powerhead to be moved quickly, allowing it to work on vertical, curved or horizontal surfaces. The system can also turn the powerhead 180º in the horizontal position.

Additionally, to further speed operation, the robot has been designed to turn through 90º travelling along the wall surface, and this together with the side movement of the powerhead eliminates the constant 'stop-start' turning of the robot.

The robotic units can operate vertically, horizontally and overhead as standard. Attachments allow removal in specialist situations, for example, underneath bridge decks or under water.

According to Aquajet,the hybrid Aquacutter model features an automated control system that optimises settings and applies the minimal force required, allowing the robot to operate selectively, with its high pressured jet of water penetrating into the weak concrete as is passes across the surface.

An innovative intelligent sensing controlled system and a patented high-pressure lance control combine to offer high efficiency and performance.

"The EDS (Equal Distance System) system optimises the angle of attack as well as ensuring the nozzle remains at the correct set distance. This in turn ensures that the optimum 'angle of attack' can be selected, maintaining maximum power from the jet, while keeping the nozzle at the correct set distance from the surface independent from the selected angle of attack.

"The angle can change by as much as +/-30º maximising concrete removal around the reinforcing bars," says Aquajet.

The hybrid systems power pack is powered by a 15 kW engine or a 15 kW electric motor, and simple 'switchover' operation ensures easy change to diesel power.

Featuring an optional extended mast height of up to 9m, the new robot offers larger, adjustable tracks to provide a variable width of between 1.5-2m for increased stability if required.

The hybrid model also incorporates a new type of steering drive to turn and twist the unit's powerhead at the increased heights to provide improved precision.

Aquajet has also developed a multi-axis system allowing the powerhead to be moved quickly, allowing it to work on vertical, curved or horizontal surfaces. The system can also turn the powerhead 180º in the horizontal position.

Additionally, to further speed operation, the robot has been designed to turn through 90º travelling along the wall surface, and this together with the side movement of the powerhead eliminates the constant 'stop-start' turning of the robot.

The robotic units can operate vertically, horizontally and overhead as standard. Attachments allow removal in specialist situations, for example, underneath bridge decks or under water.

According to Aquajet,the hybrid Aquacutter model features an automated control system that optimises settings and applies the minimal force required, allowing the robot to operate selectively, with its high pressured jet of water penetrating into the weak concrete as is passes across the surface.

An innovative intelligent sensing controlled system and a patented high-pressure lance control combine to offer high efficiency and performance.

"The EDS (Equal Distance System) system optimises the angle of attack as well as ensuring the nozzle remains at the correct set distance. This in turn ensures that the optimum 'angle of attack' can be selected, maintaining maximum power from the jet, while keeping the nozzle at the correct set distance from the surface independent from the selected angle of attack.

"The angle can change by as much as +/-30º maximising concrete removal around the reinforcing bars," says Aquajet.