A new generation of road reclamation equipment is now coming to market from key suppliers. One notable development at the recent bauma 2022 exhibition was the availability of new attachments for use on compact machines. These improved units can deliver the reclamation of road surfaces on a smaller scale, suited to urban use or utilities works for example. Meanwhile, new towed units are also on the market, offering lower costs and greater utilisation than self-powered machines.

Suited for use with skid steer loaders and compact tracked loaders, the RPM/SSL model from FAE features a 600mm-wide planing width. The unit can be used on any compact machine with the suitable high-flow hydraulic supply.

It is aimed at use on small road repaving works in urban areas, as well as utilities jobs but can also be used for road repairs on highway hard shoulders.

Weighing 1.2tonnes, the unit is 1.65m wide, features 8° of mechanical tilt and offers a maximum working depth of 250mm.

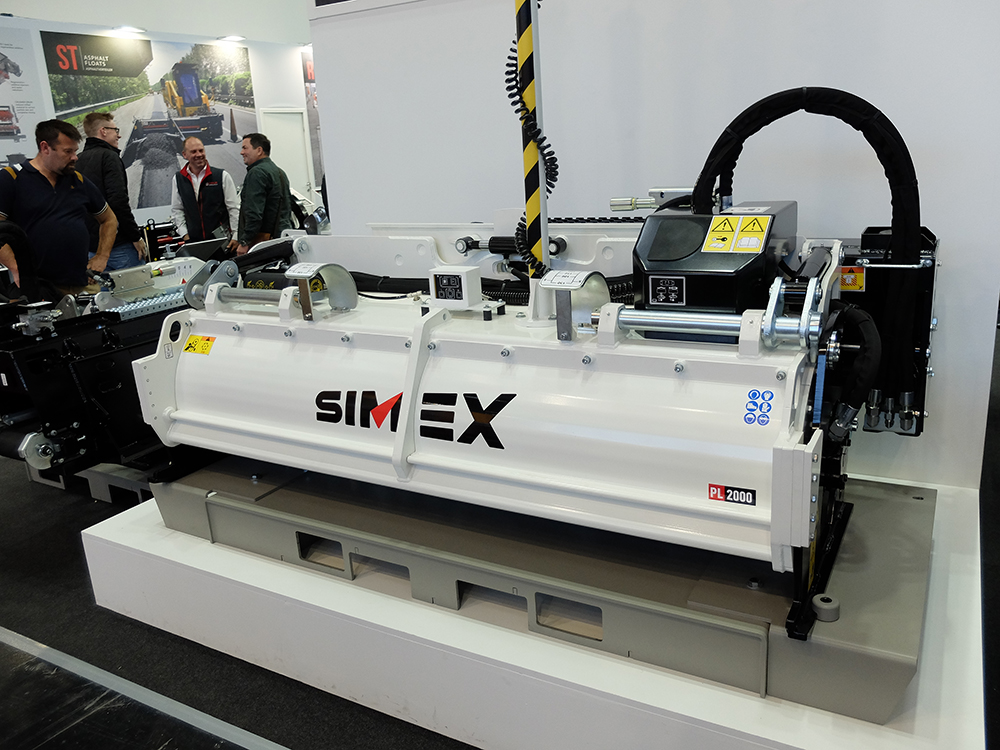

Meanwhile, Simex is expanding its range with the introduction of its new PL 2000 planer attachment. The unit is also designed for use on compact machines such as skid steer loaders or compact tracked loaders that feature the necessary high-flow hydraulic systems. This new model shares a number of technical features with Simex’s existing PL 1000, PL 1200 and PL 1500 models, but is now the largest unit from the firm, taking the place of the PL 1500 as the top-of-the-range model.

As with the PL 1500, the new PL 2000 is said to be highly versatile, powerful and productive, featuring components designed for long working life. Said to be easy to service and maintain, the PL 2000 features a 2m-wide drum and Simex claims that it is the largest planer attachment currently on the market for use with compact loaders.

The unit is said to be durable, allowing it to cope with tough operating conditions. The quality of the milling drum is said to be high due to the use of robotic welding, which ensures a rugged tooth holder featuring longevity and performance.

The independent depth adjustment of the slides on the right and left sides helps deliver flat surfaces with side-by-side passes. There is also a hydraulic side shift that allows milling flush to walls, barriers or pedestrian walkways. A floating transverse tilt means that the operator is able to keep the planer aligned to the road surface even if the base machine is not parallel to the ground. The PL units all benefit from the proven Simex self-levelling system, which ensures a constant milling depth regardless of the conditions of the road surface. Also fitted are the firm’s dust suppression system with an integrated and increased capacity water tank as well as Simex’s own Performer device, which optimises the advance rate.

The most recent addition to Wirtgen's WR recycler/stabiliser range comes in the shape of the towed WR 380 CR unit, which offers a standard working width of 3.8m but is available with smaller widths if required. As with the self-powered models in the range this is now available with the company’s new Resource Efficiency System, which offers greater automation, boosting efficiency. The company has also developed a new VARIO injection bar for binding agents that allows the injection pressure of water and bitumen to be regulated for more homogeneous distribution in the mixing chamber.

The Resource Efficiency System includes automatic steering as well as digital project site documentation. Satellite-based, the guidance system allows precise working and steers the machine using a reference cut and predefined overlap of adjacent cuts. Parameters such as width, depth, distance and area worked are recorded to generate a database for site analysis and documentation.

The addition of water and binding agents is regulated according to parameters such as the working width and depth, material density and machine advance rate. The injection bar has 16 nozzles, each of which can be activated or deactivated. The VARIO injection bar for water, bitumen emulsion and foamed bitumen also has an adjustable nozzle cross-section. The design allows the user to change injection pressure and the depth that the spray jet penetrates into the material.