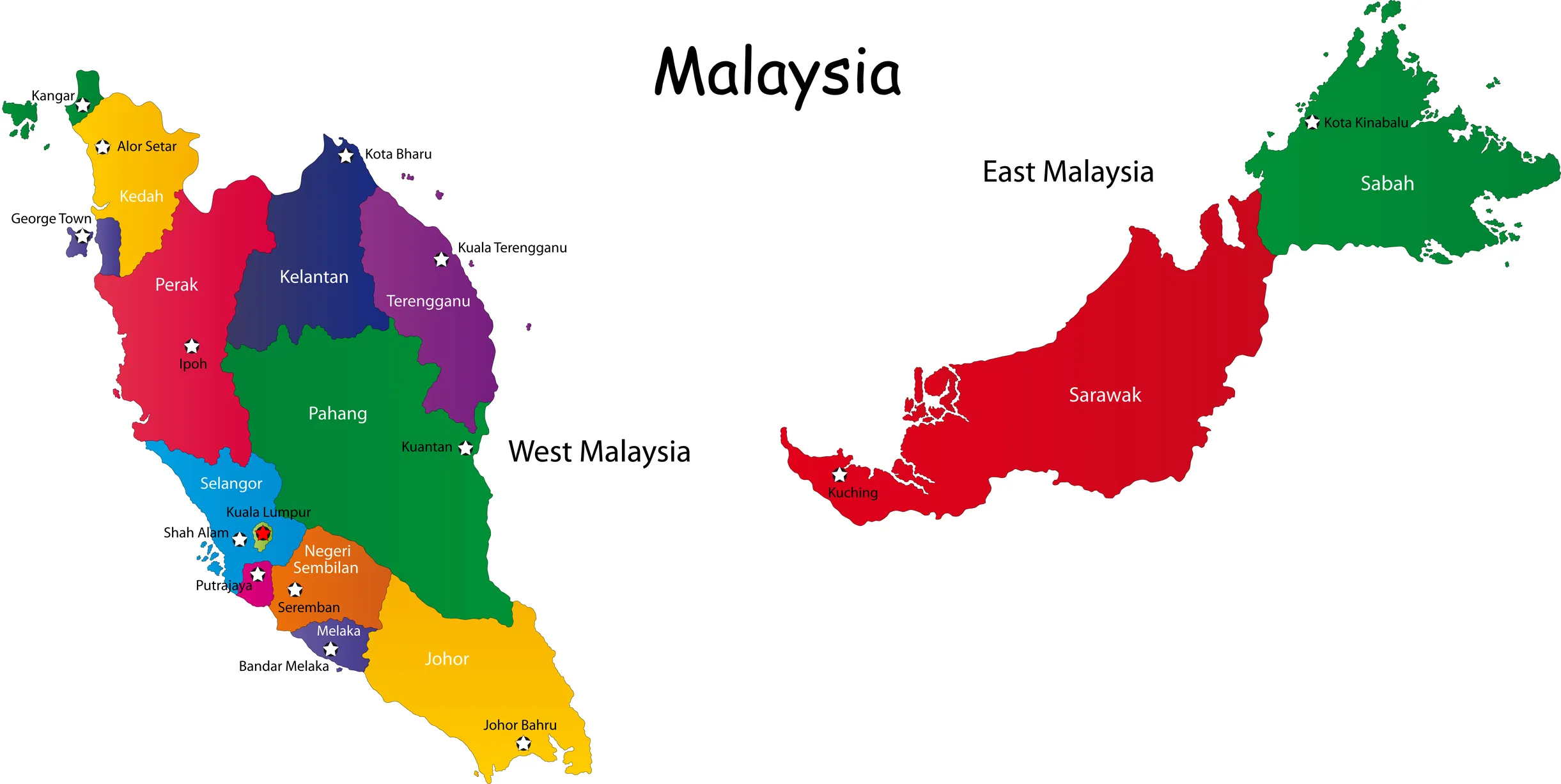

The contractor used high-performance Wirtgen cold milling machines as well as pavers from Vögele and rollers from Hamm for the rehabilitation of runway 1 at Malaysia's Kuala Lumpur International Airport (KUL).

The first part of the job for the contractor was the rehabilitation of runway 3 as part of the KUL Runway Sustainability Master Plan. The firm was then given the go-ahead to begin work on the first complete rehabilitation of runway 1, including the adjacent taxiways. The first step in this process was removing 44,000m3 of asphalt.

The large-scale asphalt removal operation was carried out by a fleet of Wirtgen milling machines designed for high performance. The planer fleet comprised several large milling machines with a milling width of 2m: two

W 195s; one W 205; two W 1900s. In addition, the contractor also used a W 1000 compact milling machine with a milling width of 1m.

The planers were used to mill an area of around 4km in length and 60m in width. All the different models involved can be used in a variety of ways. Equipped with a 2m standard milling drum, the W 195 and W 205 large milling machines, for example, can each mill to a depth of 33cm.

Due to the much higher load in the central area of the runway caused by the weight of the landing aircraft, the milling experts from contracting firm Nippon Road defined two areas, each with a different milling depth. The first area encompassed the central corridor measuring 18m-wide, and the contractor decided on a milling depth of 250mm for this section, which was continuously milled in two passes – first at a depth of 100mm, then at a depth of 150mm. The two outer strips of the runway, each 21m-wide, formed the second area where the company removed a 75mm-thick asphalt layer in a single pass.

One of the challenges was the bitumen-modified asphalt that had been in use for many years, which was very hard. This meant that selecting the right round-shank pick for the job was also essential in order to achieve maximum milling performance and a long tool life. In this case, the company opted for Wirtgen round-shank picks with a high-performance carbide tip.

The LEVEL PRO PLUS levelling system delivered a uniformly milled, even surface. Integrated into the control system, this continuously compares the current milling depth with the preset target value.

Front-loading the milled material optimised truck logistics throughout the milling operation. Continuously filling the waiting trucks kept the milling process flowing smoothly as the trucks rotated on the fly. The milled asphalt material was then reused at a nearby road construction project.

Once the milling work had been completed, pavers from Vögele and rollers from Hamm were then employed to pave and compact the new asphalt surface. Using this Wirtgen fleet the contractor was able to complete the complete rehabilitation of runway 1, including the adjacent taxiways, at Kuala Lumpur International Airport. The work will help boost traffic to and from Malaysia's busiest airport facility and is one of several transport infrastructure development projects in the country.