Productivity and profitability mean more than how many metres per minute your cold planer mills. In today’s world, precision is every bit as important as pace. Precision eliminates costly rework. It ensures crews don’t remove excess materials, and incur the associated costs in fuel, hauling and machine life. Precision also impacts the entire life—and cost—of a project by creating the proper foundation on which all subsequent work occurs. Cat® Grade and Slope for cold planers helps deliver that precision. Am

January 31, 2013

Read time: 2 mins

Productivity and profitability mean more than how many metres per minute your cold planer mills. In today’s world, precision is every bit as important as pace.

Precision eliminates costly rework. It ensures crews don’t remove excess materials, and incur the associated costs in fuel, hauling and machine life. Precision also impacts the entire life—and cost—of a project by creating the proper foundation on which all subsequent work occurs.

Cat® Grade and Slope for cold planers helps deliver that precision. Among the “precise control” benefits of the system:

• Typical setup utilises more data samples than competitive systems, providing a more accurate representation.

• Cross coupling capability improves machine responsiveness, providing superior surface quality and accuracy.

• Automatic calibration ensures consistent setup and delivers optimal performance.

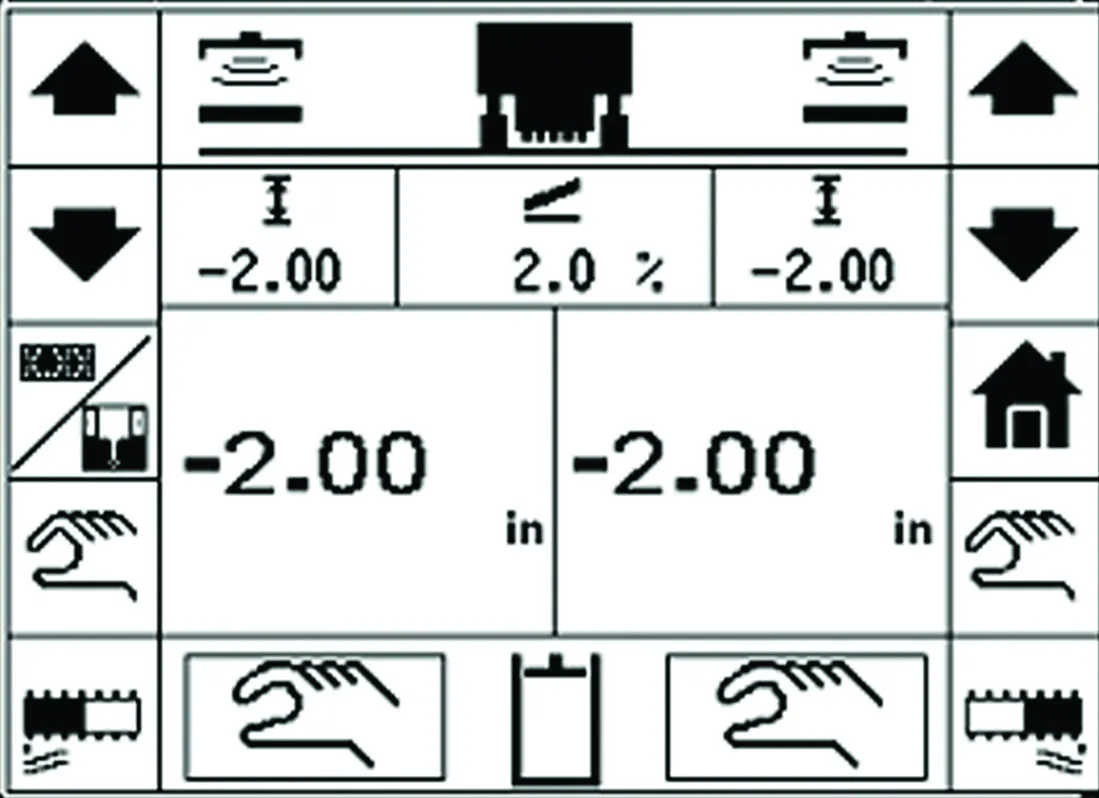

• An intuitive operator’s display makes the technology easy for crews to leverage in real-world, on-the-job conditions.

• Sonic sensors feature five ceramic transducers per unit, each far more durable than foil transducers.

• Contact and wire rope sensors have wide reference ranges, resist heat and wind, and provide clean signals for high accuracy.

The benefits of Cat Grade and Slope don’t end there.

Single-source supplier. The Cat system is a perfect match for your Cat Cold Planer. Cat Grade and Slope also enables you to take advantage of all the services available through your dealer—including support and financing.

Increased reliability. Uptime is maximised because factory installed and sealed components are built to meet the rigours of demanding milling applications and are resistant to heat, vibration and moisture.

Call your Cat Dealer to see the Cat Grade and Slope system at work. A story by4018 Caterpillar Paving %$Linker: 2 External <?xml version="1.0" encoding="utf-16"?><dictionary /> 0 0 0 oLinkExternal Click here www.paving-news.com/register/ false http://www.paving-news.com/register/ false false %> to register for your personal copy of Paving News

Precision eliminates costly rework. It ensures crews don’t remove excess materials, and incur the associated costs in fuel, hauling and machine life. Precision also impacts the entire life—and cost—of a project by creating the proper foundation on which all subsequent work occurs.

Cat® Grade and Slope for cold planers helps deliver that precision. Among the “precise control” benefits of the system:

• Typical setup utilises more data samples than competitive systems, providing a more accurate representation.

• Cross coupling capability improves machine responsiveness, providing superior surface quality and accuracy.

• Automatic calibration ensures consistent setup and delivers optimal performance.

• An intuitive operator’s display makes the technology easy for crews to leverage in real-world, on-the-job conditions.

• Sonic sensors feature five ceramic transducers per unit, each far more durable than foil transducers.

• Contact and wire rope sensors have wide reference ranges, resist heat and wind, and provide clean signals for high accuracy.

The benefits of Cat Grade and Slope don’t end there.

Single-source supplier. The Cat system is a perfect match for your Cat Cold Planer. Cat Grade and Slope also enables you to take advantage of all the services available through your dealer—including support and financing.

Increased reliability. Uptime is maximised because factory installed and sealed components are built to meet the rigours of demanding milling applications and are resistant to heat, vibration and moisture.

Call your Cat Dealer to see the Cat Grade and Slope system at work. A story by