Powerscreen is celebrating 50 years in business this year, and it will launch celebrations at the Hillhead (28-30 June, Buxton, England).

Colin Clements, global product line director said: “Powerscreen have been providing the crushing and screening industry with high quality, innovative products for 50 years and we are excited to celebrate that success with those who matter - our distributors and customers. By kicking off the celebrations at Hillhead, we will be able to showcase new and revamped equipmen

May 16, 2016

Read time: 3 mins

Cutting tools are crucial to milling machines as well as soil stabilisers and there have been key innovations for the market. 161 Atlas Copco and 2395 Wirtgen are both introducing new systems that are said to offer improved performance for milling machines, both in terms of finish quality and longevity.

Atlas Copco’s new road milling tools have been developed by the firm’s sister company Secoroc, which specialises in drilling tools. Because Secoroc has extensive experience in developing drilling tools for use in hard rock applications, the firm claims this has helped it produce a long- lasting range of products for use in road planning duties. These are aimed at use on milling machines with cutting widths of 350mm to 2.2m and are available in three basic variants, for use with asphalt (AA), concrete (AC) or for dual purpose applications (AM).

According to Atlas Copco, the new tools offer greater wear life than competing products, some 30% more than conventional units. This extended life is crucial as it allows the bits to last a full working shift, boosting machine uptime and productivity. Because there is no need to stop for tool change-outs in the middle of a job, output and efficiency are increased and tool replacement can be left until the working shift is complete. The bits also have a universal shank for versatility.

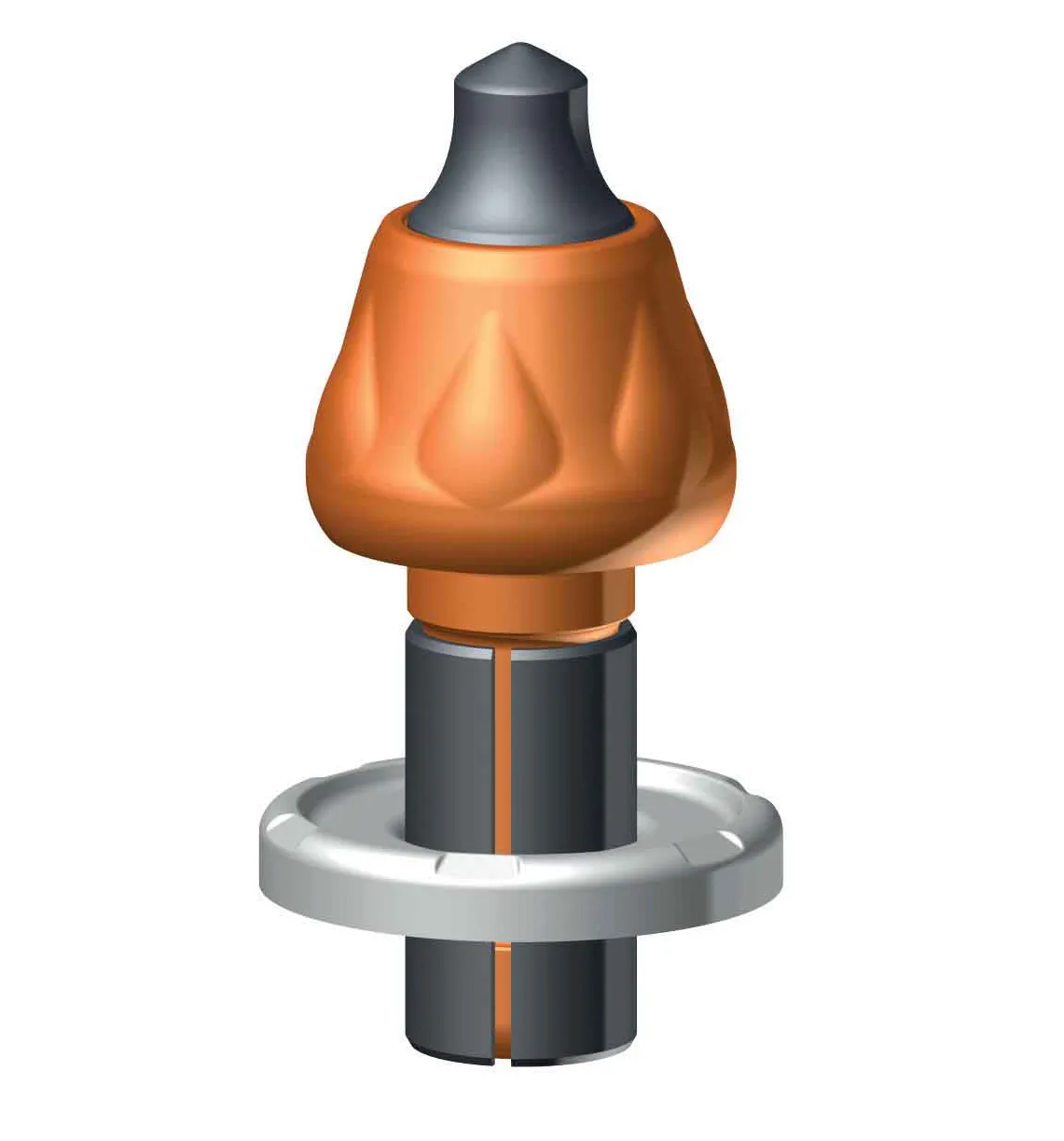

Wirtgen says that its new tools offer a long service life and high machine output and is introducing two new systems for cold recycling and soil stabilisation. The firm is launching its GENERATION Z point-attack cutting tools and its HT22 quick-change toolholder system.

The company claims that its GENERATION Z point-attack cutting tools can be used for Wirtgen cold recyclers and soil stabilisers. These new products have been revised to cater to current demands in the mixing and cutting process. A key development is that the height of the carbide base has been increased while the quality of the carbide material is precisely matched to meet working requirements. In addition, the steel body, wear plate and clamping sleeve have been optimised to extend wear properties. These features all help to extend the tool life of the cutters and to increase toolholder protection.

In addition the firm has introduced its quick-change toolholder system HT22 for the Wirtgen cold recyclers, self-powered soil stabilisers and tractor-towed stabilisers. The HT22 also benefits from a new geometrical design and improved steel quality to boost the wear material around the base and the upper and lower parts of the toolholder. This improvement helps increase service life and allows for longer service intervals, while boosting machine availability.

The company says that it has carried out extensive testing of these units, clocking up over 15,000 working hours in a variety of applications. The combination of the new HT22 and GENERATION Z components are said to improve performance across a wide range of applications in both recycling and soil stabilisation duties according to the firm.

For very high cutting performance in milling applications, Wirtgen is also offering its new PKD cutters, which feature tips made of artificial diamond and these units are said to produce a highly uniform surface while also offering longer service life.

Atlas Copco’s new road milling tools have been developed by the firm’s sister company Secoroc, which specialises in drilling tools. Because Secoroc has extensive experience in developing drilling tools for use in hard rock applications, the firm claims this has helped it produce a long- lasting range of products for use in road planning duties. These are aimed at use on milling machines with cutting widths of 350mm to 2.2m and are available in three basic variants, for use with asphalt (AA), concrete (AC) or for dual purpose applications (AM).

According to Atlas Copco, the new tools offer greater wear life than competing products, some 30% more than conventional units. This extended life is crucial as it allows the bits to last a full working shift, boosting machine uptime and productivity. Because there is no need to stop for tool change-outs in the middle of a job, output and efficiency are increased and tool replacement can be left until the working shift is complete. The bits also have a universal shank for versatility.

Wirtgen says that its new tools offer a long service life and high machine output and is introducing two new systems for cold recycling and soil stabilisation. The firm is launching its GENERATION Z point-attack cutting tools and its HT22 quick-change toolholder system.

The company claims that its GENERATION Z point-attack cutting tools can be used for Wirtgen cold recyclers and soil stabilisers. These new products have been revised to cater to current demands in the mixing and cutting process. A key development is that the height of the carbide base has been increased while the quality of the carbide material is precisely matched to meet working requirements. In addition, the steel body, wear plate and clamping sleeve have been optimised to extend wear properties. These features all help to extend the tool life of the cutters and to increase toolholder protection.

In addition the firm has introduced its quick-change toolholder system HT22 for the Wirtgen cold recyclers, self-powered soil stabilisers and tractor-towed stabilisers. The HT22 also benefits from a new geometrical design and improved steel quality to boost the wear material around the base and the upper and lower parts of the toolholder. This improvement helps increase service life and allows for longer service intervals, while boosting machine availability.

The company says that it has carried out extensive testing of these units, clocking up over 15,000 working hours in a variety of applications. The combination of the new HT22 and GENERATION Z components are said to improve performance across a wide range of applications in both recycling and soil stabilisation duties according to the firm.

For very high cutting performance in milling applications, Wirtgen is also offering its new PKD cutters, which feature tips made of artificial diamond and these units are said to produce a highly uniform surface while also offering longer service life.