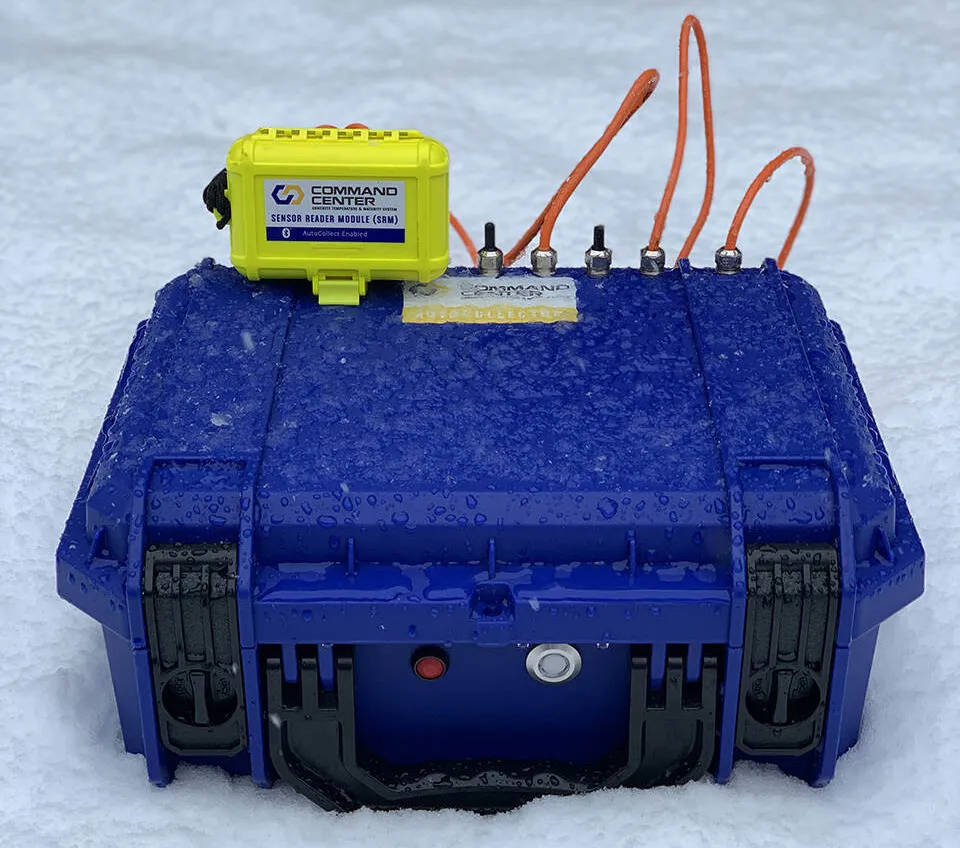

Fully autonomous off-site collection of data as is now possible with Transtec’s Command Center, a concrete temperature and maturity monitoring system.

Since 2003, Transtec says that its COMMAND Center has been used on thousands of projects worldwide for all types of concrete applications. COMMAND Center - ASTM C1074 compliant - can be used for monitoring temperature and maturity in any concrete placement and is commonly used for concrete pavement repair.

The COMMAND Center system is also suitable for measuring concrete temperature and maturity in any mass concrete placement, such as found in bridges - piers, structural columns, mat slabs, girders, footings and thick slabs.

Now, by removing the necessity of on-site personnel to collect data, COMMAND Center AutoCollect, project teams - from subcontractors and testing firms to owners, engineers and architects - can measure and log concrete temperature history, calculate maturity and evaluate in-place strength while away from the jobsite.

The AutoCollector box is rugged and weatherproof and can be left outside at a jobsite. The hardware requires four D-cell batteries for power.

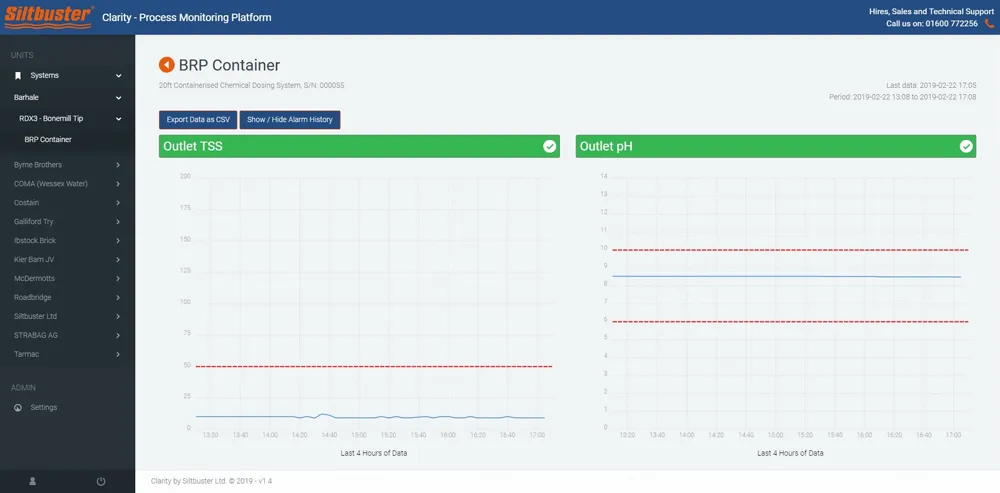

In addition, COMMAND Center has released a cloud sharing platform for users - the COMMAND Center Cloud. It works with or without the AutoCollect option, allowing teams to sync project files automatically across multiple devices and protect files with user privileges.

COMMAND Center AutoCollect uses a cellular signal to automatically send sensor data to the COMMAND Center Cloud where teams can access it in real-time from anywhere - on or off the jobsite. Users can receive real-time alerts via text message or email when their concrete approaches temperature limits or achieves estimated target strength.

COMMAND Center AutoCollect offers alternative download options and data redundancies to reduce potential data loss, so teams can be sure their concrete data is safe, says Transtec.