Guntert & Zimmerman is offering a new system of telescopic end sections for its concrete pavers, which allow contractors to change widths between pours. These are also said to meet tight smoothness specifications and allow a contractor to carry out width changes quickly.

February 15, 2012

Read time: 1 min

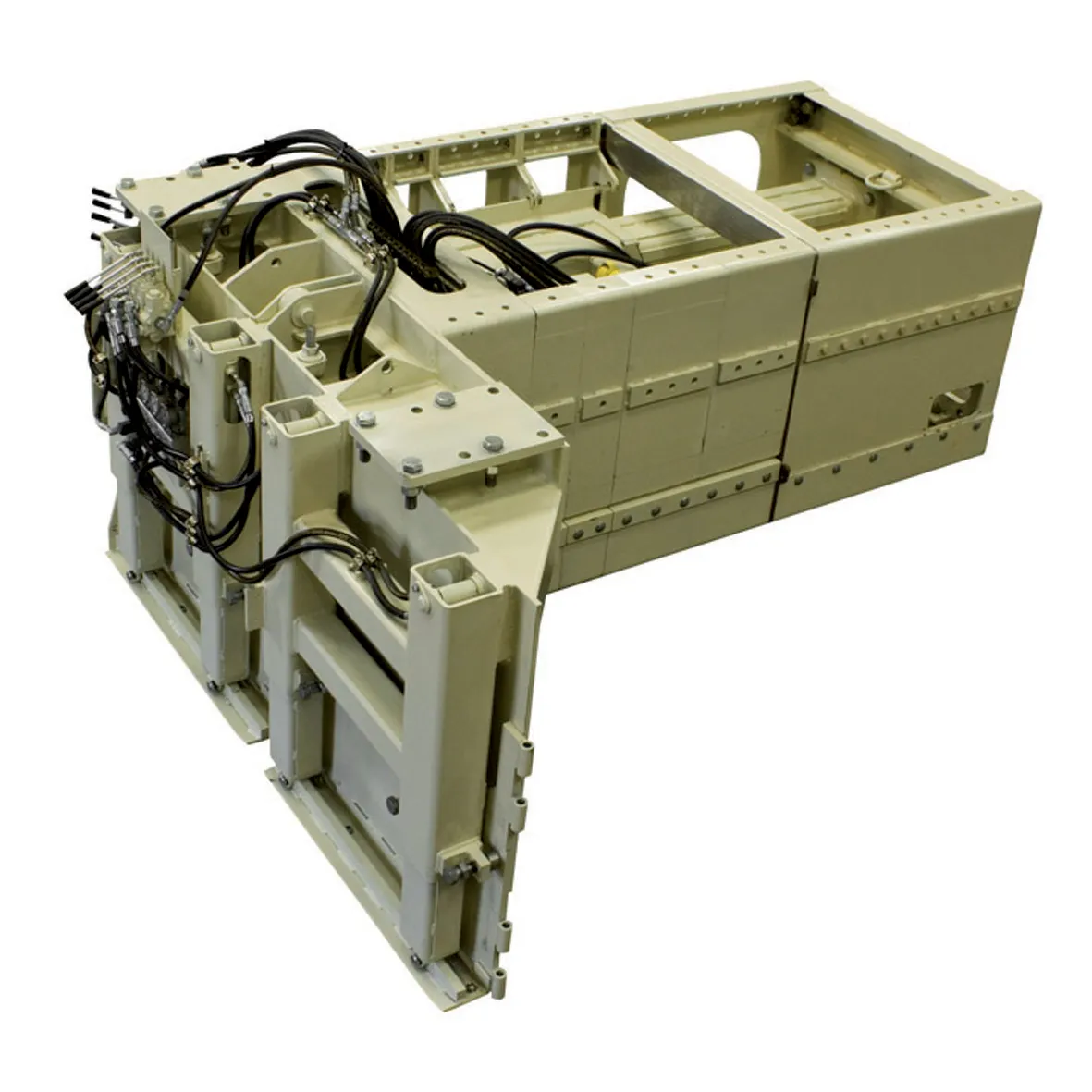

Guntert & Zimmerman is offering a new system of telescopic end sections for its concrete pavers, which allow contractors to change widths between pours. These are also said to meet tight smoothness specifications and allow a contractor to carry out width changes quickly. The units offer an additional 1.8m for both the G&Z S850 and S1500 slipform pavers.

The firm says that a width change which could typically take a four person crew no less than a full day can now be performed by one or two people in two hours. The new end sections can be specified as an option during the purchase of a new G&Z Slipform Paver or can be retrofitted to existing G&Z machines. The units are also available as an option on the firm's new S600 Multi-Purpose slipform paver.

The firm says that a width change which could typically take a four person crew no less than a full day can now be performed by one or two people in two hours. The new end sections can be specified as an option during the purchase of a new G&Z Slipform Paver or can be retrofitted to existing G&Z machines. The units are also available as an option on the firm's new S600 Multi-Purpose slipform paver.