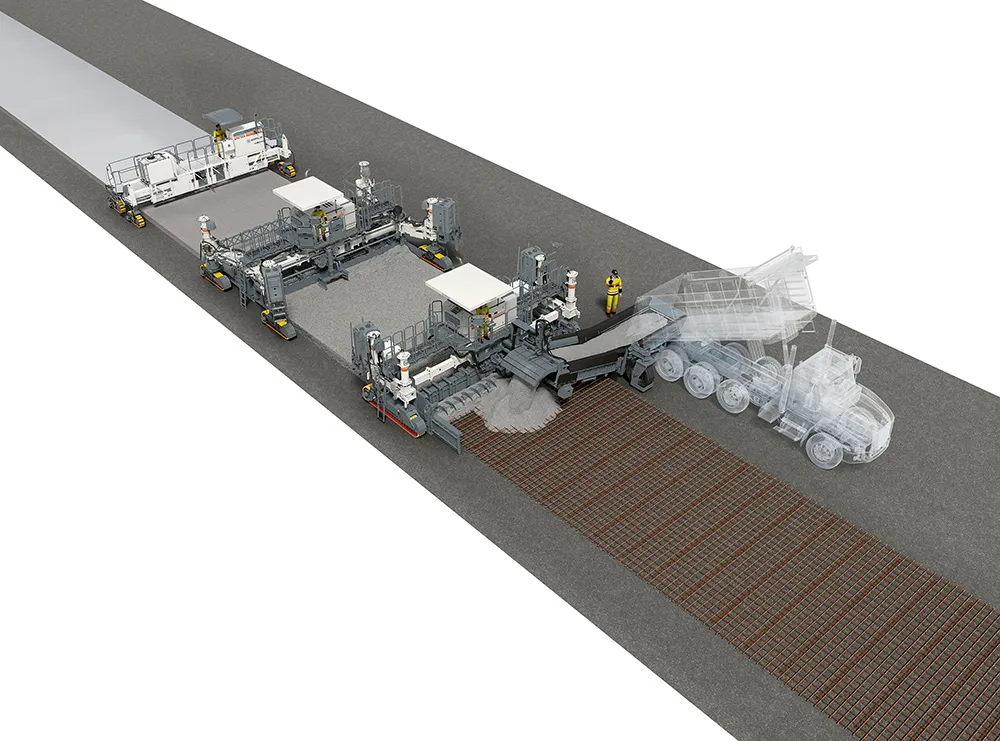

The WPS 102i placer/spreader is suited to use in applications when road surfaces and paths are paved over pre-placed steel rebar. For these duties, concrete can often only be supplied to the machine from the side and requires the need of a placer/spreader. As the leading machine in a paving train, they travel over the pre-placed steel rebar ahead of the slipform paver and the texture curing machine. A truck feeds the concrete from the side, and the placer/spreader then evenly distributes it across the entire working width. The new WPS 102i is Wirtgen’s latest addition to its range of two-track placer/spreaders. The concrete can be placed for working widths from 4-12m at thicknesses of up to 500mm. The modular machine features standard hydraulic quick-change couplings and can be quickly and easily reconfigured as the more compact WPS 62i. This ensures fast transport from job to job and maximum machine availability. The WPS 102i can be precisely controlled by stringline scanning, stringless 3D applications, or

Autopilot 2.0 from Wirtgen.

The firm is also offering SP 94i, a fully modular, 10m class inset slipform paver that can be used in a range of applications such as surfacing wide roads and highways, airport aprons, taxiways, and runways. The four track paver can also be seen fitted with the firm’s TeleMold, which allows fast and versatile alteration of the working width by up to 1m on each side, resulting in an overall increase of 2m. Short reconfiguration times mean that paving contractors can benefit from high availability and utilisation rates. In addition to the quick-change elements of the mold, the TeleMold is also equipped with a quick-change system for the metering gate and vibrator mountings. This means that crews can pave and reconfigure the working width all on the same day. The system can be fitted to SP 64i, SP 94i, and SP 124i slipform pavers.

And also new is a version of the SP 15i that features a retractable extension for the operator’s platform. This offers a better overview of the paving results, the concrete feeding system, the transfer hopper, and of the inside of the compaction chamber of the mold. In addition, the firm has developed the new Curb Depressor Mold, fitted with a hydraulically adjustable inset integrated in the mold. This is used for the construction of lowered curb profiles, such as for driveway access, which reduces the need for manual reworking.