In the Philippines, a GOMACO GP-2400 concrete paver has been carrying out slipforming work on a project that will help alleviate traffic congestion. CM Pancho Construction Company, based out of Quezon City, Philippines, recently purchased a new GOMACO GP-2400 two-track paver. The firm had previously owned a GOMACO GT-6300 and made the decision to upgrade to a new machine, receiving the new unit earlier this year. The company put its new GP-2400 to work immediately on the Plaridel Bypass Road project near th

November 29, 2012

Read time: 2 mins

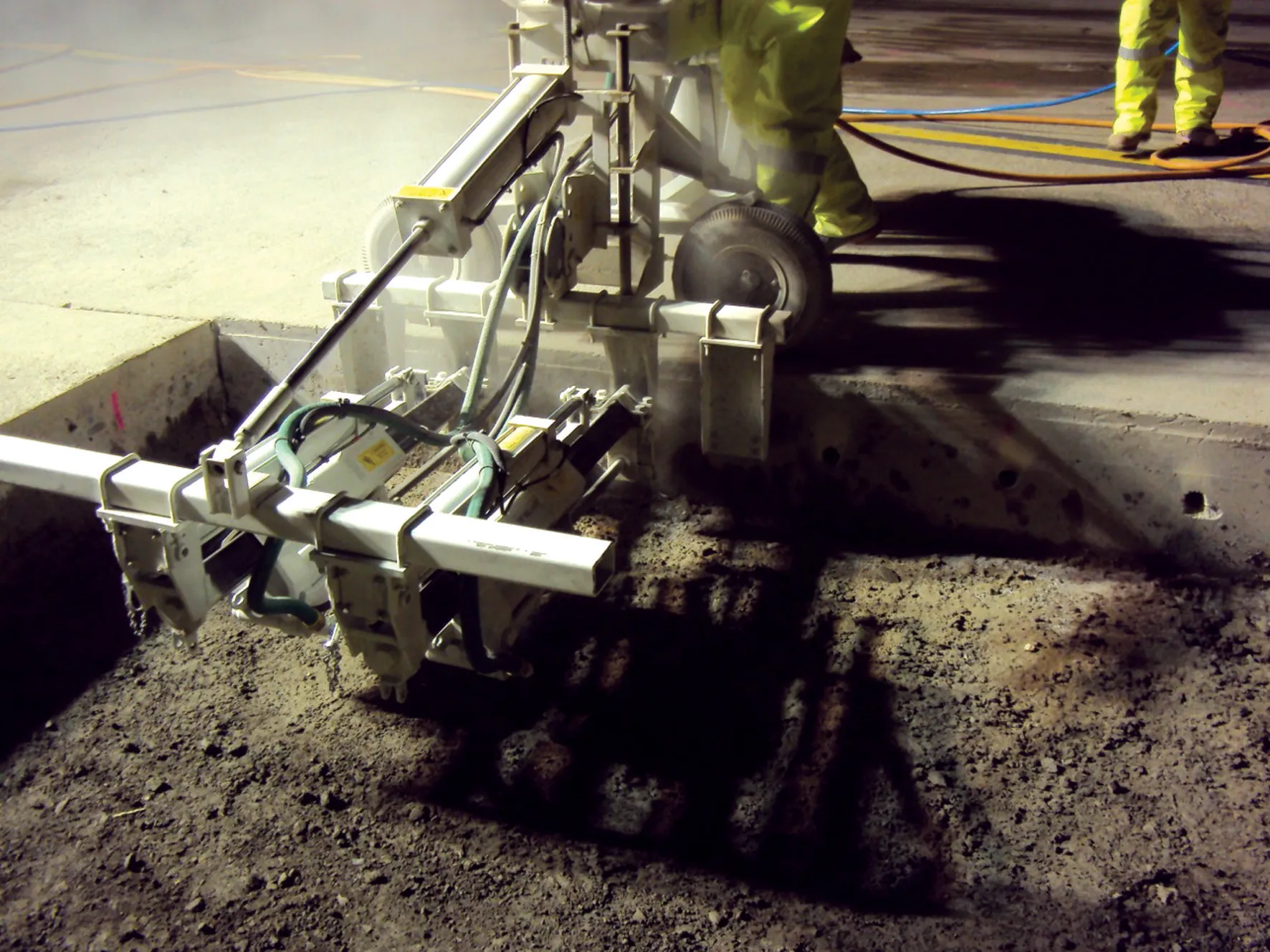

In the Philippines, a 218 Gomaco GP-2400 concrete paver has been carrying out slipforming work on a project that will help alleviate traffic congestion.

CM Pancho Construction Company, based out of Quezon City, Philippines, recently purchased a new GOMACO GP-2400 two-track paver. The firm had previously owned a GOMACO GT-6300 and made the decision to upgrade to a new machine, receiving the new unit earlier this year.

The company put its new GP-2400 to work immediately on the Plaridel Bypass Road project near the town of Bustos. The project involved building a new 6km long, two-lane highway. In areas, the highway reaches up to four lanes wide. The GP-2400 slipformed the new roadway in paving passes 3.5m wide and 300mm thick.

For this job the paver used a left-hand sidebar inserter. This was used to insert 16mm diameter bars measuring 600mm long every 600mm.

The bypass forms part of the country's2569 Department of Public Works and Highways' plan to improve mobility and promote development. The bypass will also help ease serious traffic congestion in the Bulacan province and improve accessibility to schools, hospitals, and markets for the people living in the province.

CM Pancho Construction Company, based out of Quezon City, Philippines, recently purchased a new GOMACO GP-2400 two-track paver. The firm had previously owned a GOMACO GT-6300 and made the decision to upgrade to a new machine, receiving the new unit earlier this year.

The company put its new GP-2400 to work immediately on the Plaridel Bypass Road project near the town of Bustos. The project involved building a new 6km long, two-lane highway. In areas, the highway reaches up to four lanes wide. The GP-2400 slipformed the new roadway in paving passes 3.5m wide and 300mm thick.

For this job the paver used a left-hand sidebar inserter. This was used to insert 16mm diameter bars measuring 600mm long every 600mm.

The bypass forms part of the country's