Precision paving performance has been achieved on a major road project in Germany, using

The BAB A9 Autobahn is one of Germany’s most important roads, connecting the German cities of Berlin and Munich over a total distance of 529km. The route runs from Brandenburg through Saxony-Anhalt, Saxony, Thuringia and into Bavaria.

The 19km widening job for the A9 between Triptis and Schleiz was based for the first time in Germany using a new model of public-private partnership, with payment dependent on the quality of service provided. In practice, any defects in quality and any limitation on availability will result in a reduction of the payment to the operator during the 20-year concession.

To meet the lifetime requirements the consortium carrying out the work,

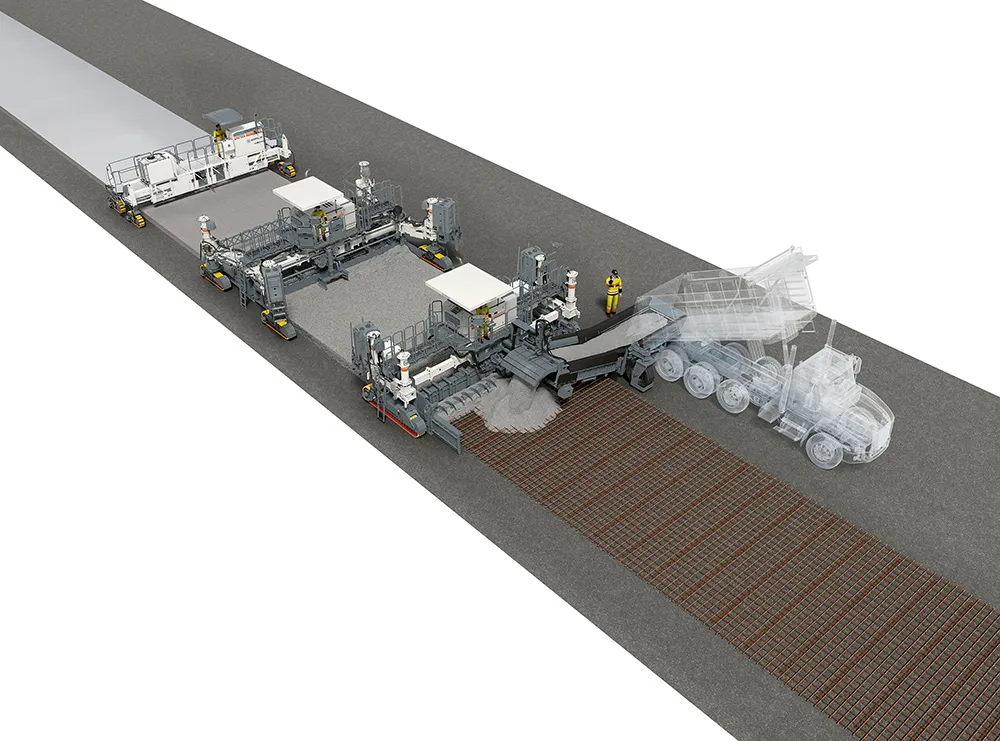

The work required laying the surface for six motorway lanes extending 19km has required some 165,000m3 of concrete. On the A9 job site, the two Wirtgen pavers laid down the two-layer concrete pavement in just one pass at a rate of around 400-500m/day.

The SP1500L paver laid the subgrade. The 230mm-thick bottom-layer concrete was paved true to line and level and compacted by an internal vibrator, while the machine simultaneously embedded dowels and tie bars in it. This yields a homogeneous base for the 70mm-thick top-layer concrete.

The top-layer concrete is installed immediately after the bottom-layer concrete, so as to ensure optimal interlocking of both layers. The concrete for the top-layer is provided via the bottom-layer concrete paver from a receiving hopper with a charging conveyor and placed in front of the second slipform paver, the SP1500.

The machine then distributes this material across the entire paving width with its spreading plough, installs the top-layer concrete wet-in-wet when passing over it and simultaneously compacts it. The finishing beam and super smoother produce the desired optimum surface finish: during the paving process, a finishing beam is deployed across the roadway while an oscillating super smoother operates in the direction of travel of the paver.

The concrete pavement is additionally sprayed with a TCM 1800 curing unit across the entire working width immediately after paving. This prevents rapid evaporation and the formation of cracks.