A key launch for the concrete paving range from the firm is its innovative SP 20(i) Offset Paver, which is designed for versatility and to handle a range of applications. The unit will be able to handle the production of concrete safety barriers with a height of up to 2m and the paving of flat surfaces with widths of up to 2.5m.

This highly adaptable offset paver is said to offer customers a combination of productivity and mobility. Despite the large paving widths and heights it offers, the machine has a low transport weight and compact dimensions. This allows the machine to be moved quickly and easily from one site to another, helping to increase its utilisation rate.

Meanwhile, the firm is also offering new capabilities for its proven compact SP 15(i) slipform paver. This versatile machine has been used successfully in a wide range of applications around the world for many years. However, a new option will be the Curb Depressor Mold, which allows automated paving of lowered kerb profiles, as are often found on driveways. The paving process can proceed without interruption and the need for manual reworking is significantly reduced.

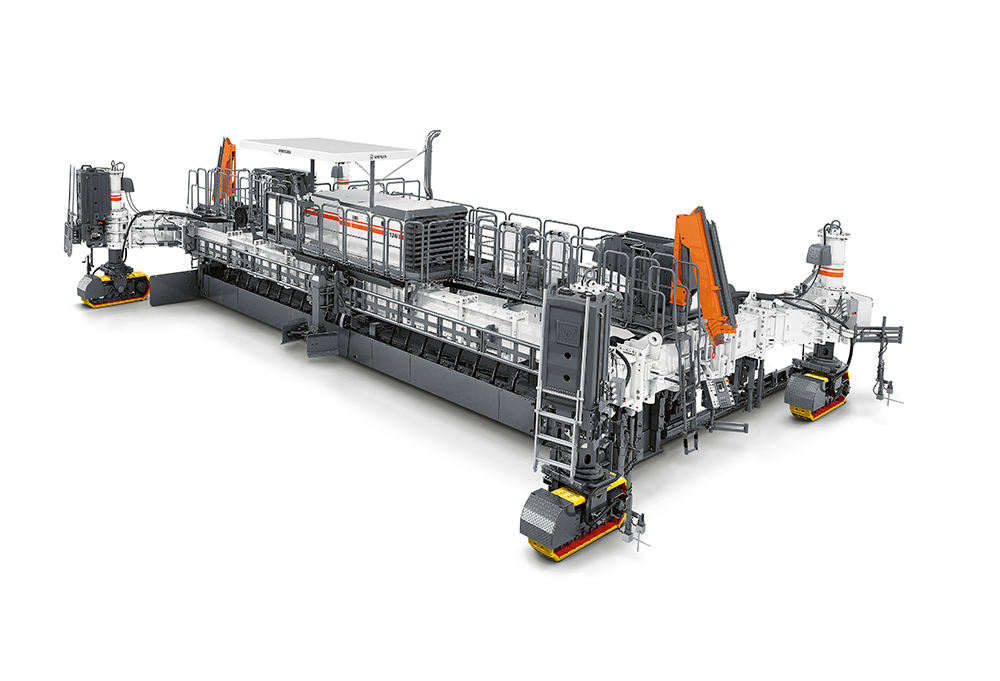

And also new from Wirtgen’s extensive concrete paving equipment range is a new version of the SP 124(i) paver. The four-track machine can be configured for paving at a working width of 12m and suits use in highway and runway paving applications.

The latest version of the machine is now being offered with the latest generation integrated dowel bar inserter.

The dowel bars are extracted from the magazine by a chain feed system using an endless chain and automatically transported to the insertion location. Smart cylinders with displacement sensors then position the dowel bar inserter at the required locations and with high precision, according to the firm. The high degree of automation reduces the proportion of manual work required, increases process reliability, and the cost-effectiveness of the process.

Also benefiting from improvements is Wirtgen’s AutoPilot 2.0 package for stringless paving. This control system offers an alternative to the conventional method of mechanically scanning a stringline.

The system controls height adjustment and steering of the machine and is available for all offset pavers and placer/spreaders in the range. A GNSS signal and, depending on the configuration, various local sensors serve as a reference.

The system allows fast and precise paving of tight radii and complex geometries. The system is operable from a tablet PC, which also supports the generation and editing of terrain models.

Wirtgen AutoPilot 2.0 is the only system that offers machine control and stringless control for concrete paving in one.