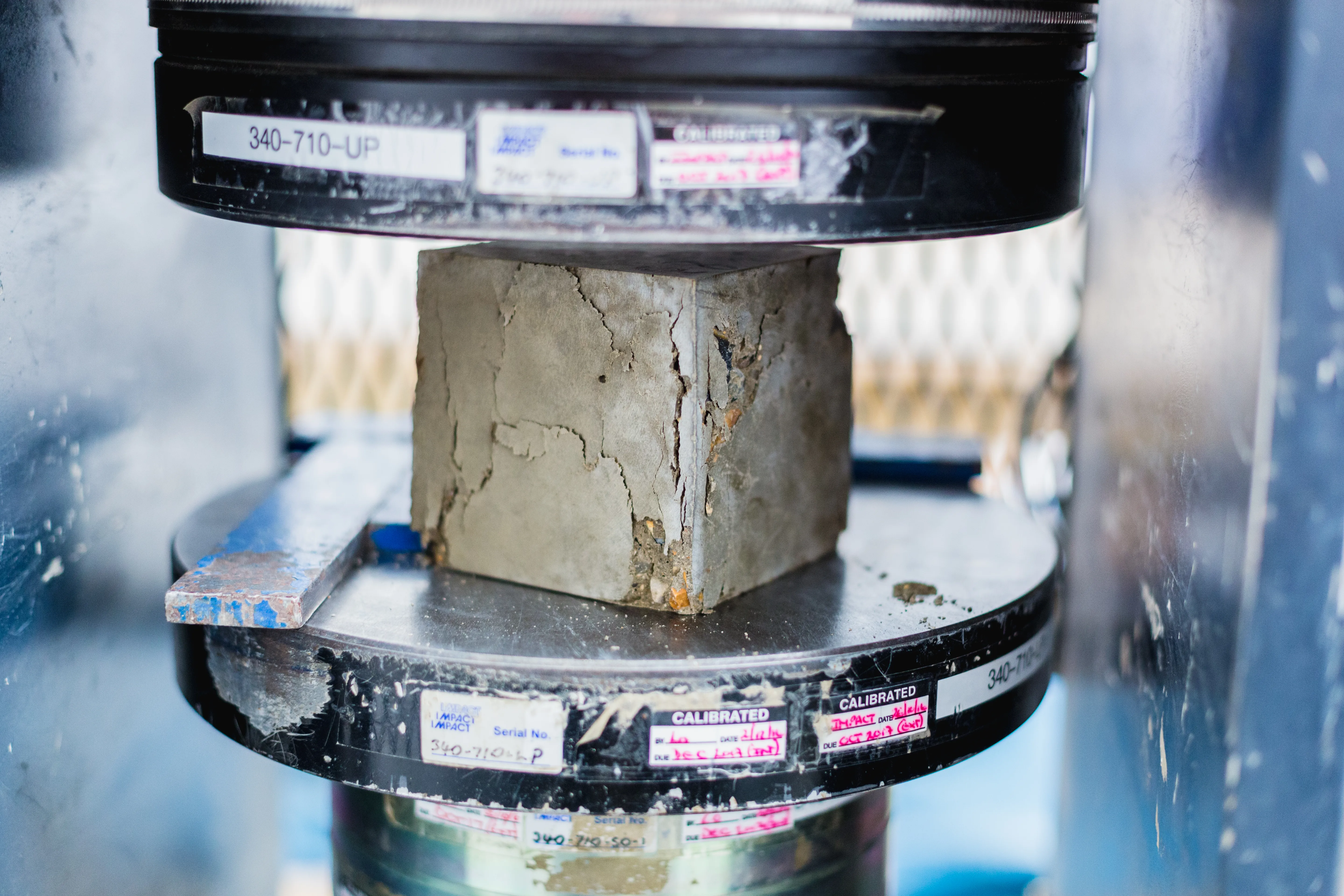

Researchers at Purdue University in the United States have developed a hydrophobic sealant that could prevent potentially damaging fluids from entering concrete pores.

Paul Imbrock, founder and president of Environmental Concrete Products – the university’s spin-off company - said the firm’s Fluid iSoylator product can be used to protect new and existing concrete.

"Our product is absorbed into dry concrete's pore network to create a hydrophobic barrier that prevents potentially damaging fluids from en

October 9, 2015

Read time: 2 mins

RSSResearchers at Purdue University in the United States have developed a hydrophobic sealant that could prevent potentially damaging fluids from entering concrete pores.

Paul Imbrock, founder and president of Environmental Concrete Products – the university’s spin-off company - said the firm’s Fluid iSoylator product can be used to protect new and existing concrete.

"Our product is absorbed into dry concrete's pore network to create a hydrophobic barrier that prevents potentially damaging fluids from entering," Imbrock said. "Along with protecting concrete from the elements, Fluid iSoylator is derived from soybean oil and is safe to handle and apply. Its physical properties also make it possible to be adapted for other potential uses, including a combination paint-and-sealing product."

Imbrock said traditional concrete sealants on the market create a film on the surface of concrete through a chemical reaction between components mixed together or with oxygen.

"Although this approach works well in ideal conditions, the film might be damaged by traffic or other abrasions. It becomes counterproductive, then, because fluids can enter the area where the film is damaged, but the film also prevents them from evaporating, leaving them susceptible to freezing," he said.

"Fluid iSoylator is different because when it enters the concrete's pores, it remains fluid regardless of traffic or abrasions. The pores are filled with the material, which prevents other fluid from entering."

Imbrock said Environmental Concrete Products has launched the Fluid iSoylator product, developed relationships with investors and contracted a partnership with an Indiana-based soy biofuel producer that has provided the company with the means to manufacture the product.

"In conjunction with our partners, we are perpetually testing derivative products and methods to reduce production costs," he said. "Along with large-scale concrete consumers, we look to connect with landscapers and construction companies to protect concrete that already exists, such as driveways, patios and sidewalks of their existing customers."

The technology was licensed to Environmental Concrete through the Purdue Research Foundation Office of Technology Commercialisation. More than 20 startups based on Purdue intellectual property were launched during the 2015 fiscal year. A video about Environmental Concrete Products is available by clicking here.

Paul Imbrock, founder and president of Environmental Concrete Products – the university’s spin-off company - said the firm’s Fluid iSoylator product can be used to protect new and existing concrete.

"Our product is absorbed into dry concrete's pore network to create a hydrophobic barrier that prevents potentially damaging fluids from entering," Imbrock said. "Along with protecting concrete from the elements, Fluid iSoylator is derived from soybean oil and is safe to handle and apply. Its physical properties also make it possible to be adapted for other potential uses, including a combination paint-and-sealing product."

Imbrock said traditional concrete sealants on the market create a film on the surface of concrete through a chemical reaction between components mixed together or with oxygen.

"Although this approach works well in ideal conditions, the film might be damaged by traffic or other abrasions. It becomes counterproductive, then, because fluids can enter the area where the film is damaged, but the film also prevents them from evaporating, leaving them susceptible to freezing," he said.

"Fluid iSoylator is different because when it enters the concrete's pores, it remains fluid regardless of traffic or abrasions. The pores are filled with the material, which prevents other fluid from entering."

Imbrock said Environmental Concrete Products has launched the Fluid iSoylator product, developed relationships with investors and contracted a partnership with an Indiana-based soy biofuel producer that has provided the company with the means to manufacture the product.

"In conjunction with our partners, we are perpetually testing derivative products and methods to reduce production costs," he said. "Along with large-scale concrete consumers, we look to connect with landscapers and construction companies to protect concrete that already exists, such as driveways, patios and sidewalks of their existing customers."

The technology was licensed to Environmental Concrete through the Purdue Research Foundation Office of Technology Commercialisation. More than 20 startups based on Purdue intellectual property were launched during the 2015 fiscal year. A video about Environmental Concrete Products is available by clicking here.