A milling machine from Bomag has been carrying out an important portion of the work needed for a four-lane expansion of a busy route in Southern Germany

Widening work has been carried out on the B85 route from Amberg to Pittersberg in Bavaria to boost its capacity. The 2.6km section was prioritised as being in urgent need of improvement by the Federal transport Ministry. Construction work commenced in mid-2017, starting with preparation works and the project includes a cloverleaf interchange to connect t

April 20, 2018

Read time: 3 mins

A milling machine from Bomag has been carrying out an important portion of the work needed for a four-lane expansion of a busy route in Southern Germany

Widening work has been carried out on the B85 route from Amberg to Pittersberg in Bavaria to boost its capacity. The 2.6km section was prioritised as being in urgent need of improvement by the Federal transport Ministry. Construction work commenced in mid-2017, starting with preparation works and the project includes a cloverleaf interchange to connect the B85 as well as the industrial area also being developed with the A6 Autobahn.

The contractor, local firm Fiedler, brought in a new BM 2200/75 milling machine to carry out the total removal of the old pavement structure. The existing road, which will become the Schwandorf-Amberg carriageway, is benefiting from a new surface, but to allow this the old road structure has had to be removed down to the subsoil.

Fiedler is a milling specialist with expertise in removing asphalt and concrete road surfaces and has a fleet that includes other172 Bomag planers such as the BM 600/15 and BM 1300/35 models.

Due to the tight construction schedule, full removal had to be completed before the first frosts at the end of 2017 to allow the subsequent stage of construction to proceed on schedule. For this €10 million project, Fiedler opted to bring in the new BM 2200/75 model.

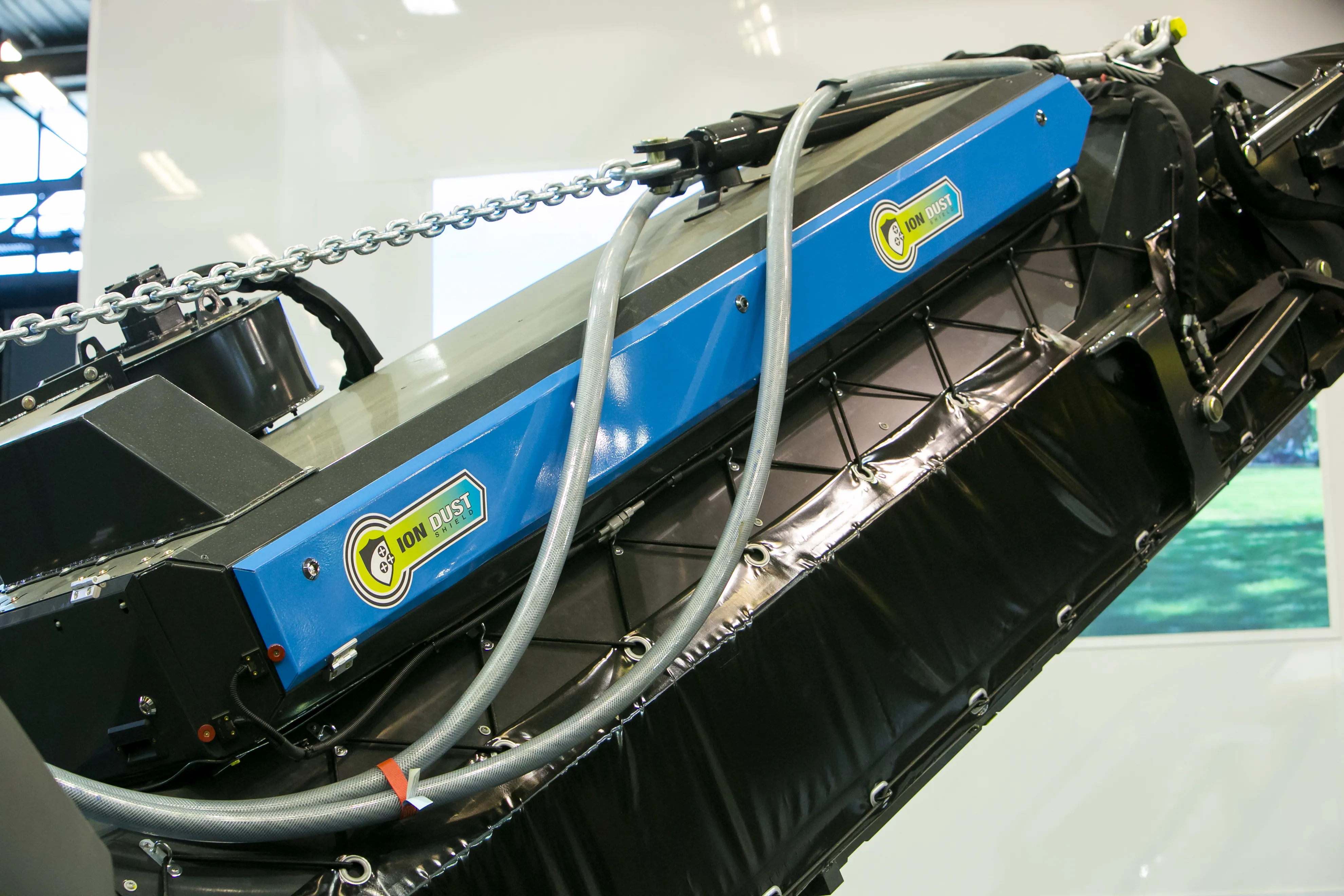

The Bomag machine appealed to the contractor as it offers a high degree of versatility and transportability, despite its size and power. The design features a quick change system for the milling box and drum. This allows the milling box to be removed and reinstalled in just 30 minutes, aided by quick-release hydraulic couplings instead of the usual bolted connections. By removing the milling box and drum the machine weight is less than 60tonnes, which makes it easier to transport by road. In addition, the hydraulic folding conveyor further eases road transport by making the machine shorter and more compact, according to the contractor.

Another important factor for the contractor was that the ability to change the milling box and drum quickly allowed different cutting set-ups to be used more readily for different applications. The firm offers a wide range of milling drums in its portfolio for different applications including a standard milling drum, a fine milling drum, and a Powerdrum, each available in 2m and 2.2m widths for milling depths down to 330mm.

The surface removal work for the extension of the B85 has been carried out in two stages. Firstly, the surface course was removed to an average depth of 40mm. For the second milling step, the bearing course was removed by an average 260mm. Although mixed materials and differing layer thicknesses were found in the course of milling work on the B85, the BM 2200/75 was able to cope with these varying materials and thicknesses, in readiness for the new road.

Widening work has been carried out on the B85 route from Amberg to Pittersberg in Bavaria to boost its capacity. The 2.6km section was prioritised as being in urgent need of improvement by the Federal transport Ministry. Construction work commenced in mid-2017, starting with preparation works and the project includes a cloverleaf interchange to connect the B85 as well as the industrial area also being developed with the A6 Autobahn.

The contractor, local firm Fiedler, brought in a new BM 2200/75 milling machine to carry out the total removal of the old pavement structure. The existing road, which will become the Schwandorf-Amberg carriageway, is benefiting from a new surface, but to allow this the old road structure has had to be removed down to the subsoil.

Fiedler is a milling specialist with expertise in removing asphalt and concrete road surfaces and has a fleet that includes other

Due to the tight construction schedule, full removal had to be completed before the first frosts at the end of 2017 to allow the subsequent stage of construction to proceed on schedule. For this €10 million project, Fiedler opted to bring in the new BM 2200/75 model.

The Bomag machine appealed to the contractor as it offers a high degree of versatility and transportability, despite its size and power. The design features a quick change system for the milling box and drum. This allows the milling box to be removed and reinstalled in just 30 minutes, aided by quick-release hydraulic couplings instead of the usual bolted connections. By removing the milling box and drum the machine weight is less than 60tonnes, which makes it easier to transport by road. In addition, the hydraulic folding conveyor further eases road transport by making the machine shorter and more compact, according to the contractor.

Another important factor for the contractor was that the ability to change the milling box and drum quickly allowed different cutting set-ups to be used more readily for different applications. The firm offers a wide range of milling drums in its portfolio for different applications including a standard milling drum, a fine milling drum, and a Powerdrum, each available in 2m and 2.2m widths for milling depths down to 330mm.

The surface removal work for the extension of the B85 has been carried out in two stages. Firstly, the surface course was removed to an average depth of 40mm. For the second milling step, the bearing course was removed by an average 260mm. Although mixed materials and differing layer thicknesses were found in the course of milling work on the B85, the BM 2200/75 was able to cope with these varying materials and thicknesses, in readiness for the new road.