• A new quiet, fuel-efficient and reliable Cat C7.1 302 HP (225kW) US EPA and CARB Tier 4f / EU Stage V, 6-cylinder diesel engine which gives low operating cost and years of productive life. Minimum 5,000-hour diesel particulate filter service interval and 500-hour oil change interval enable low cost operation supported by a world-class product support offered through global Cat dealer network. Note: For markets where ultra-low sulphur diesel fuel is not available, G&Z supplies a Cummins Tier 3 QSB6.7 260 HP (194kW) engine.

• Like all G&Z paver power units, there is wide visibility around the power unit and is maintained under the paver operator’s feet so there is a full view of, and access to, the concrete liquification hopper and the front tie bar inserter.

• Like all G&Z paver power units, there is wide visibility around the power unit and is maintained under the paver operator’s feet so there is a full view of, and access to, the concrete liquification hopper and the front tie bar inserter.

One other enhancement to the S600 patented VariWidth Tractor Frame is extended width capability out to 34’ (10.36m). This was made possible with new, heavier duty male telescopic extension tubes and new 1.5m wide bolt-in, fixed frame and hose extensions for the tractor frame.

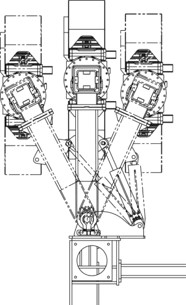

• The VariWidth, double telescopic, tractor frame allows width change from 8' to 22' (2.4-6.9m) in a few minutes with the help of the patented camber adjusting, support rollers and hydraulic clamping puck system. The hydraulic clamps securely lock the male telescopic tubes in a fixed position relative to the tractor centre module. This is critical for accurate steering.

• G&Z’s innovative and patented tunnel in the bolster design (where male telescopic tubes can pass) offers a very wide telescopic range. This patented design eliminates the need for two stage, telescopic extensions per side that sag undesirably at wider widths which adversely impact steering and grade control.

• G&Z’s innovative and patented tunnel in the bolster design (where male telescopic tubes can pass) offers a very wide telescopic range. This patented design eliminates the need for two stage, telescopic extensions per side that sag undesirably at wider widths which adversely impact steering and grade control.

• To change the tractor frame width, the paver operator flips a switch to release the hydraulic clamping pucks on one side of the machine. Then using the crawler tracks in the 90º steering mode, walks the tractor frame out to the desired width, supported by the rollers. There is no need to support the tractor frame centre module prior to telescoping.

• In addition to the tractor frame quickly telescoping 7’ (2.13m) per side, the hoses and cables from the centre module to the bolsters are mounted on a hose hinge and telescope in the same range along with the access walkway with handrailing is optionally available 7’ of telescopic ability.

• The S600 is now available with two types of bolt-in, tractor frame extensions options.

• The S600 is now available with two types of bolt-in, tractor frame extensions options.

- With the original, 2.5’ (0.75m) tractor frame extensions, bolted in on both sides of the tractor, the tractor frame can telescope from 13’ (12’ [3.5m] is possible) to 27’ (3.9-8.4m) and by moving the paving kit mounts to the outside of the bolster out to 31’ (9.5m) without the DBI.

- With the new, heavy duty 5’ (1.5m) tractor frame extensions, bolted in on both sides of the tractor, the tractor frame can telescope from 18’ (16’ [5m] is possible) to 32’ (5.5-9.75m) and by moving the paving kit mounts to the outside of the bolster out to 34’ (10.4m) without the DBI.

For the airport paving job, the machine was working at 31’ wide.

The other patented productivity features that have been available on the S600 since 2010 are still available and highly recommended.

• Crawler tracks can to be moved in and out on the fly by the groundman or operator while the crawler track automatically stays straight ahead so the paver crawler track can be quickly and easily moved around and by obstacles. From any swing bolster angle, the S600 crawler tracks equipped with “AccuSteer” slew drives can be turned 90° to the direction of paving and walk and steering in this position. This feature saves time and space manoeuvring on the jobsite.

• Crawler tracks can to be moved in and out on the fly by the groundman or operator while the crawler track automatically stays straight ahead so the paver crawler track can be quickly and easily moved around and by obstacles. From any swing bolster angle, the S600 crawler tracks equipped with “AccuSteer” slew drives can be turned 90° to the direction of paving and walk and steering in this position. This feature saves time and space manoeuvring on the jobsite.

• The S600 Paver equipped with SmartLeg can be transformed into the transport mode in a matter of a few minutes with stands under the bolster with the crawler track lifted off the ground or without stands by using the 90° steering mode and walk each crawler track in an arch, to a pre-programmed, outboard position.

• The S600 swing legs are designed long enough so front crawler tracks can swing inside edge of pavement required for narrow track lines. There is plenty of room in front of the rear crawler track to safely insert side tie bars.

• The S600 swing legs are designed long enough so front crawler tracks can swing inside edge of pavement required for narrow track lines. There is plenty of room in front of the rear crawler track to safely insert side tie bars.

• The S600 SmartLeg design allows the paver to be transformed into the transport mode semi-automatically in a matter of minutes.

• The S600 is claimed to be the narrowest profile paver in its class. The distance from edge of pavement to widest point on the paver is 2’-0” (610 mm).