New material placer being introduced by G&Z – Mike Woof writes. Guntert & Zimmerman is now lifting the wraps from its new MP550 material placer, having announced last year that design work was underway. This machine is designed to boost throughput and overall productivity on site, while being versatile, easy to maintain and service and offering low running costs. According to the firm, the MP550 is the most versatile material placer on the market as it can handle a wide variety of concrete slumps as well as

March 3, 2015

Read time: 3 mins

RSSNew material placer being introduced by G&Z – Mike Woof writes

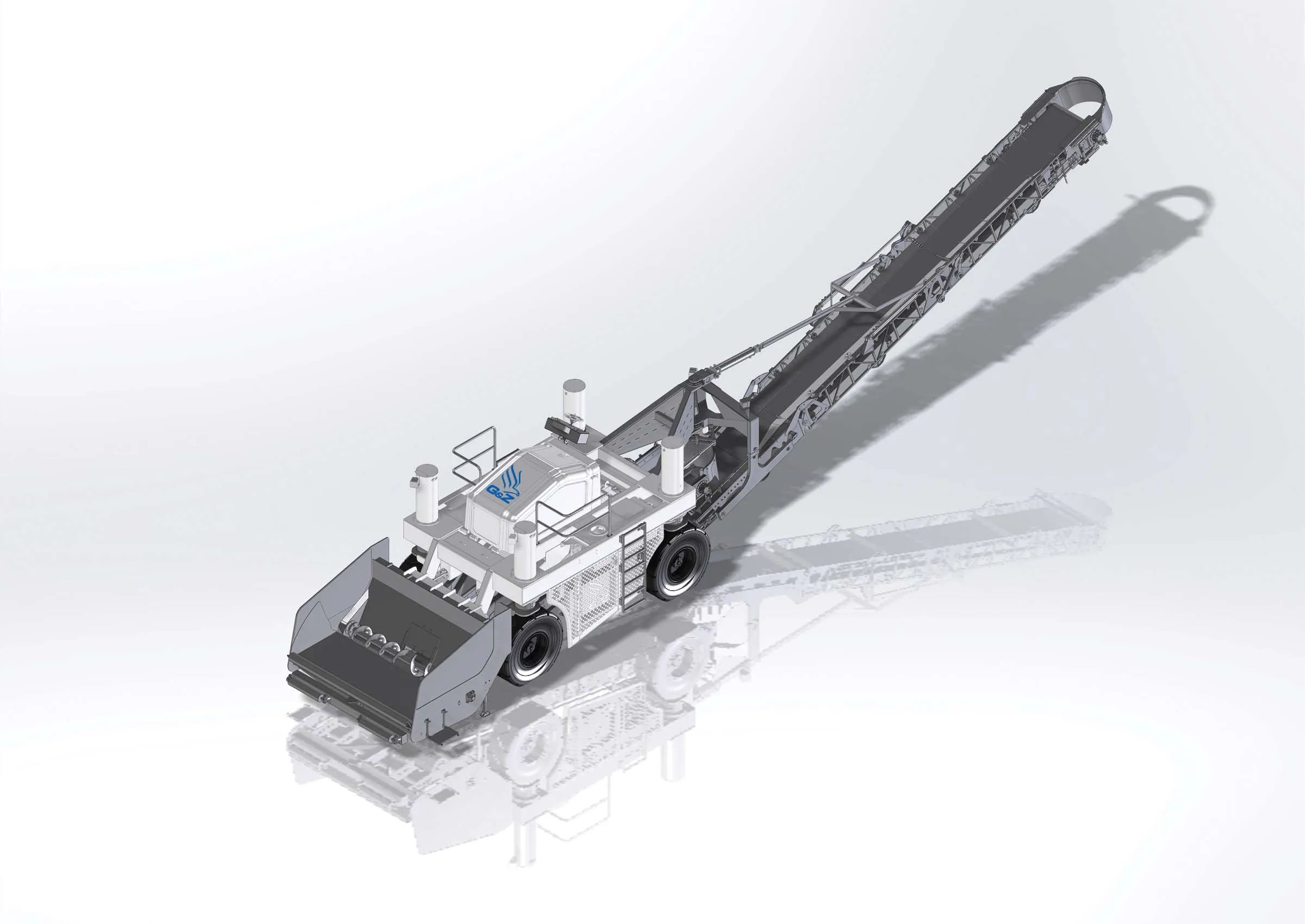

225 Guntert & Zimmerman is now lifting the wraps from its new MP550 material placer, having announced last year that design work was underway. This machine is designed to boost throughput and overall productivity on site, while being versatile, easy to maintain and service and offering low running costs.

According to the firm, the MP550 is the most versatile material placer on the market as it can handle a wide variety of concrete slumps as well as dry materials. The machine has four-wheel drive to maximise traction, dual axle steering and an inside turning radius of just 3.66m. This offers greater ease of movement in and around the job site. Its concrete hopper design has been designed to reduce dump box height with a front lip only 584mm off the ground, allowing loading by a wide range of trucks. The MP550’s 10.7m long swing conveyor can pivot 170° and has a hinge point near the tail pulley for ease of clearing barrier walls and other obstructions while minimising material discharge height.

The firm claims that the MP550 delivers the highest concrete spreading production on the market, with a large hopper that can hold up to 4.2m3. The hopper’s novel front gate is designed with a hydraulically adjustable rubber seal to minimise spillage, while the hopper can be specified with hydraulically adjustable front pusher rollers.

The company says that it has designed the MP550 to be easy to maintain and clean after use. The conveyors and their components are said to be readily accessible for servicing and cleaning. The tail end of the transfer conveyor meanwhile can quickly be lowered or even disconnected for cleaning and maintenance, and each conveyor is also designed for ease of belt replacement.

The MP550 is at present powered by an economical Tier 4 Interim engine, with a simple solution for upgrade to Tier 4 Final status and an Eco-Mode feature to help reduce fuel consumption by up to 35%.

Other savings for running costs include the choice of tyres instead of tracks and in addition, the MP550 is said to be quick and easy to transport for contractors.RSS

According to the firm, the MP550 is the most versatile material placer on the market as it can handle a wide variety of concrete slumps as well as dry materials. The machine has four-wheel drive to maximise traction, dual axle steering and an inside turning radius of just 3.66m. This offers greater ease of movement in and around the job site. Its concrete hopper design has been designed to reduce dump box height with a front lip only 584mm off the ground, allowing loading by a wide range of trucks. The MP550’s 10.7m long swing conveyor can pivot 170° and has a hinge point near the tail pulley for ease of clearing barrier walls and other obstructions while minimising material discharge height.

The firm claims that the MP550 delivers the highest concrete spreading production on the market, with a large hopper that can hold up to 4.2m3. The hopper’s novel front gate is designed with a hydraulically adjustable rubber seal to minimise spillage, while the hopper can be specified with hydraulically adjustable front pusher rollers.

The company says that it has designed the MP550 to be easy to maintain and clean after use. The conveyors and their components are said to be readily accessible for servicing and cleaning. The tail end of the transfer conveyor meanwhile can quickly be lowered or even disconnected for cleaning and maintenance, and each conveyor is also designed for ease of belt replacement.

The MP550 is at present powered by an economical Tier 4 Interim engine, with a simple solution for upgrade to Tier 4 Final status and an Eco-Mode feature to help reduce fuel consumption by up to 35%.

Other savings for running costs include the choice of tyres instead of tracks and in addition, the MP550 is said to be quick and easy to transport for contractors.RSS