With more than 30,000 take-offs and landings a year, Jefferson City Memorial Airport (JEF) is one of the most heavily frequented airports in Missouri. Thousands of visitors travel through it every day on their way to the government and congress offices in the state capital on the Missouri River. At the end of April 2016, work commenced on the reconstruction of a runway approximately 1.8km in length. However the project was of note as it was one of the first to see the use of

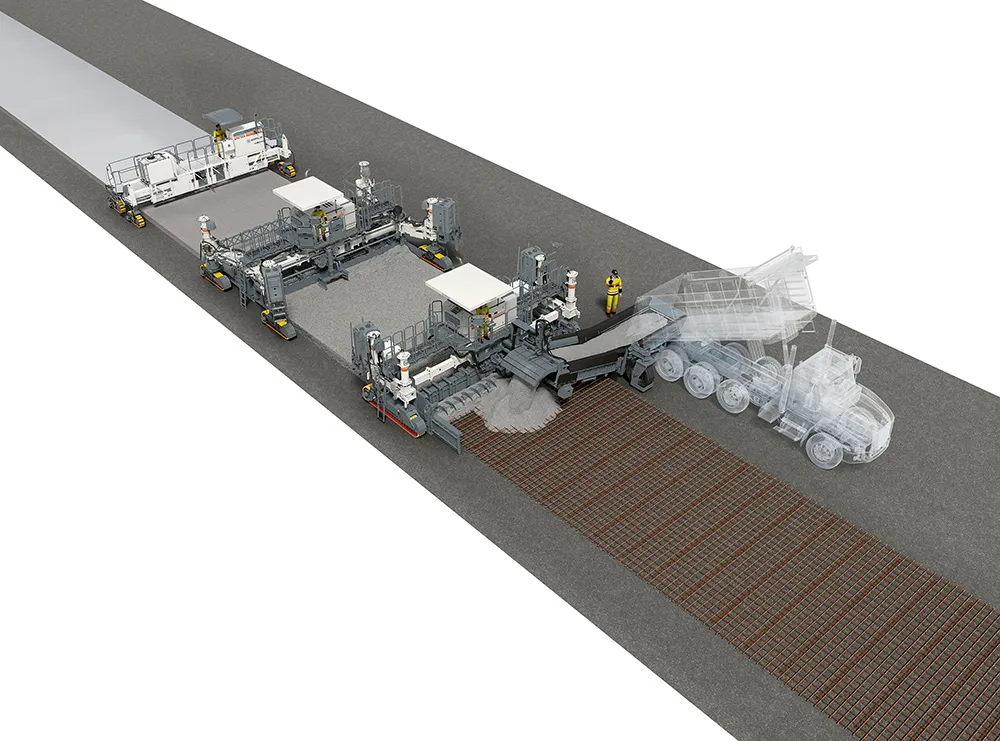

The owner of the slipform paver, the Lehman Construction Company, got to work on the site as soon as the two days required for set-up of the machine were over. The 250mm-thick concrete layer was paved on a prepared base course which was also 250mm thick. Apart from dowel bars spaced at transverse intervals of 450mm and longitudinal intervals of 3.8m, the runway does not have any continuous reinforcement. Some 20,000m³ of concrete in total was laid on the runway, which is 1.8km long by 30m wide.

“The specification for surface evenness allowed for a maximum permitted deviation of 7”/mile (180mm/1.61km)”, explained Tim Nash, director Concrete Products Wirtgen at Wirtgen America. “Since the machine first went into operation, we have not had a deviation of more than 1”/mile (25.4mm/1.61km) on any paving job. Usually, in fact, it was 0.”

Lehman achieved this high standard of evenness with practically unchanged factory settings and no major modifications on the job site. The productivity was also high: each day the SP 94i paved concrete over an area up to 750m long and 7.5m wide. Due to high daytime temperatures of over 30°C, paving largely took place during the night hours.

The authorities also had stringent requirements on how the edges of the runway were shaped – the angle was to be exactly 90°. “The representatives of the construction inspection authority confirmed to us that they had never yet seen such precise edges,” Tim Nash recalls. “A vertical concrete edge is crucial for laying the next slab,” confirms John Gibson, Test Engineer at Burns & McDonnell, the company responsible for inspecting the construction work. “And this machine delivered a very good edge”.

Lehman’s decision to buy the new Wirtgen SP 94i slipform paver has been justified. Kenny Lehman, Owner and Director of the Lehman Construction Company, put it this way: “We wanted to try out something new, because I’d heard that this machine could achieve a smoother surface than machines of competitors. With the SP 94i we’re actually achieving even better surface accuracy than we had expected.” The process of setting the concrete paver up at the job site – which includes positioning and zeroing the crawler tracks and the swivel arms – is quick and easy with the SP 94i. “The crawler units work very well and the set-up time for the sensor system is short. All the settings can be done quickly,” says Lehman.

“The specifications in our contracts are frequently very strict, so everything has to be just so,” the owner added. “This machine will boost our competitiveness. The requirements on motorways can be met much more easily with the SP 94i. We’re really happy with this slipform paver.” The first project was a complete success and Lehman delivered the runway to the high quality required. Now the pilots taking off and landing at Jefferson City Memorial Airport can put this to the test.