The new Maynard H Jackson Jr International Terminal at Hartsfield- Jackson Atlanta International Airport is now open for business. The 111,484m2 terminal features 12 gates, eight security checkpoints, separate levels for arrivals and departures, as well as a 148,831m2 concrete apron for aircraft to park on arrival. Archer Western won the contract to slipform the concrete apron, replace the existing Taxiway D, as well as other utilities and embankment work. The firm brought in one of its GOMACO paving trains

October 12, 2012

Read time: 4 mins

The new Maynard H Jackson Jr International Terminal at Hartsfield- Jackson Atlanta International Airport is now open for business. The 111,484m2 terminal features 12 gates, eight security checkpoints, separate levels for arrivals and departures, as well as a 148,831m2 concrete apron for aircraft to park on arrival.

The design of the apron dictated short paving runs, which limited daily slipform production. A 0.5% fall, to keep water from ponding on the apron, was also an exacting aspect of the project.

“Maintaining the 0.5% fall and keeping water from ponding on the new apron was one of the more difficult challenges,” said Justin Cooper, assistant project manager for Archer Western. “That is super flat and not a lot of room to play with. With the GSI, we were able to check the overall smoothness constantly and make sure our set-up was right on.”

The new apron was slipformed on top of a 229mm thick soil-cement sub-base,with concrete produced on-site by a mobile batch plant. The project used a standard P501 concrete with a low slump of 19mm and around 15 trucks were used to haul 7.6m3 concrete loads to the paving train.

“We used the PS-2600 on the project for the ride quality it gives us,” Cooper said. “We had good ride numbers using this stiff mix. The PS-2600 helped out and provided the initial knockdown of the concrete, which helped provide a nice smooth finish behind the GHP- 2800 paver.”

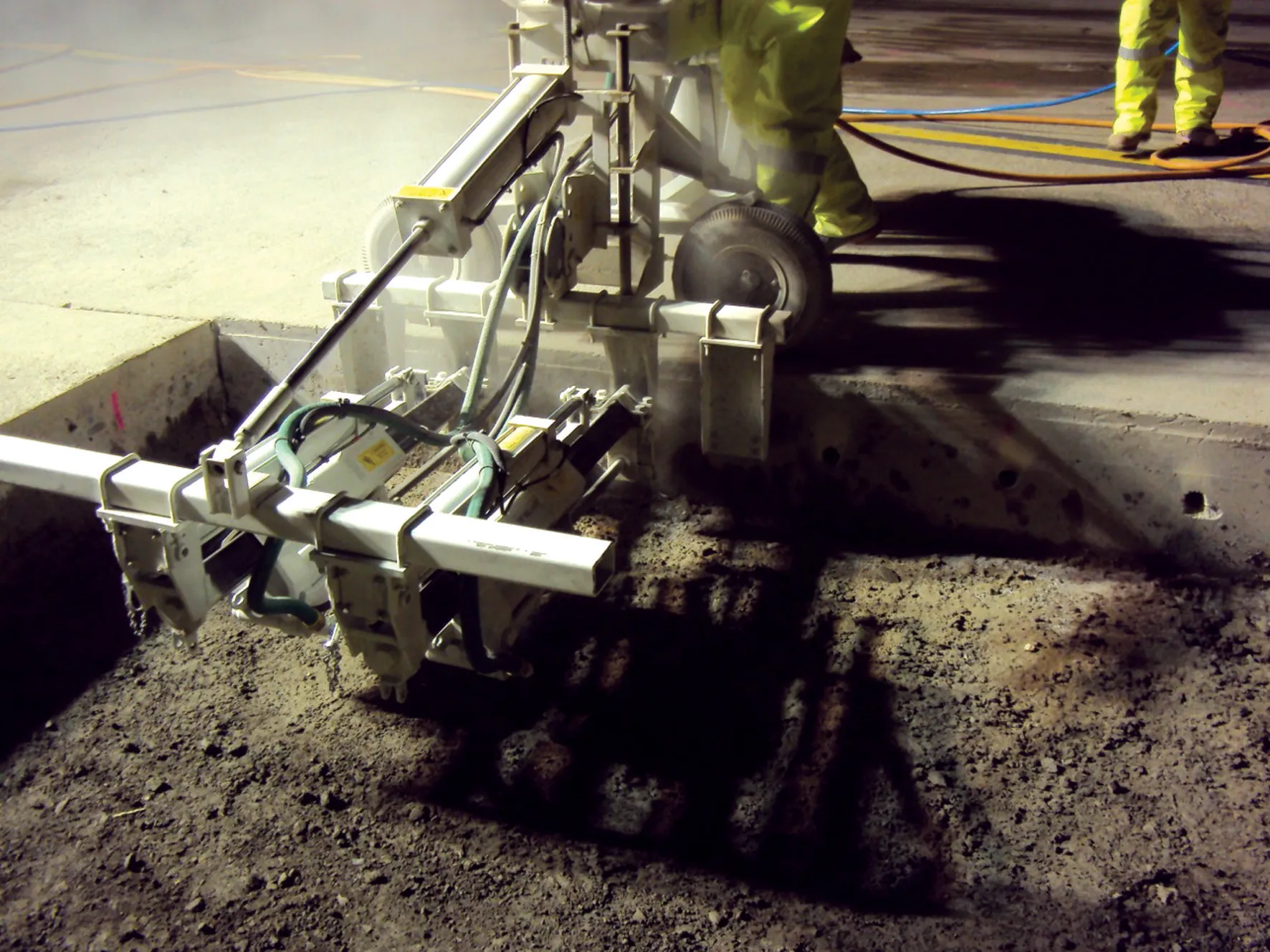

The GOMACO two-track GHP-2800 slipformed the apron in paving passes 7.6m wide and 508mm thick. Dowel baskets were placed on grade every 7.6m, with some areas of welded wire reinforcing depending on the shape of the slab.

“We had very little finishing work behind the paver and found the more we worked with the slab, the worse the numbers typically were,” Cooper said.

“The straight edging to adjacent lanes was important to ensure ponding water would not be held on the relatively flat apron.” Archer Western’s daily paving production was limited by the site layout.

The GOMACO 9500 placer was used in several areas for hand pours around embankment utilities, fuel pits, underdrains, and other various utilities. The firm also had to work around other contractors building the new terminal. Average slipform paving production was 1147m3/day, while the best production day reached 1529m3.

“The way the project was set up, the lanes weren’t long enough to have a really good day,” Cooper explained, adding that the firm did achieve 1376m3 and 1453m3 pours, “…but mostly we could only go as far as the lanes would take us.”

Finishing work behind the paver was kept to a minimum. The firm applied a burlap drag by hand and then used the GOMACO T/C-600 texture/cure machine to apply a white spray cure.

All of the new pavement was profiled by Archer Western’s GSI machine. The airport specification states that as soon as the concrete has hardened sufficiently, and within 24 hours of placement, the contractor will test the pavement surface.

Seven GSI units were mounted on the GSI machine, as required by the airport’s specification. The individual GSI units trace lines 305mm, 1.2m, and 2.4m off the joint line on each side, and also along the centerline of each 7.6m wide paving pass.

The airport also requires Archer Western to use a 4.9m rolling straight edge to check the new pavement. Surface deviations exceeding 6mm in 4.9m in any direction require correction. Any deviation over 13mm must be removed and replaced.

“On road projects we just run the sensors in the wheel paths, but since this is an airport project, the GSI is checking the entire width of the slab with seven sensors,” Cooper said. “It was definitely challenging, to say the least,” Cooper said. “We completed on time and delivered the project within spec. The airport in Atlanta is big on concrete paving and they make sure that we deliver the highest quality paving in the country at the airport.”