The STP 1010 Blow Patcher can repair holes and road surface damage without the need for milling machines and pavers. The driver of the vehicle can carry out the entire repair process, using a joystick in the cab. Meanwhile, the supply of sufficient aggregates and emulsion is controlled electronically.

The Blow Patcher comes in two versions. Each version carries 2,000litres of emulsion. The STP 1010/4000 version carries 4m³ of aggregate and the STP 1010/6000 version carries 6m³ of aggregate. Aggregates and emulsion are separate in their own bins until application. This prevents loss of material if work has to stop at some stage.

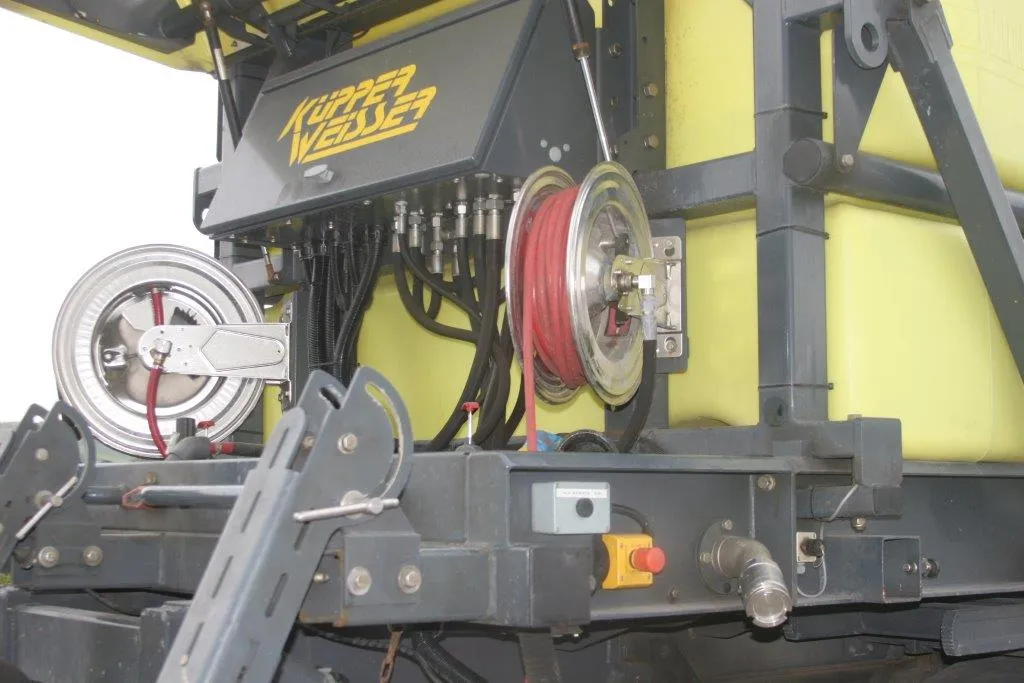

Power comes from a 55kW Hatz diesel, while a hydraulic pump drives patching machine functions and a Kaeser OMEGA blower supplies air to blast the aggregate into place. Two hydraulic pumps handle emulsion processes. The larger pump is for circulation and loading/unloading of the emulsion while the smaller unit is for spraying.

The introduction of the emulsion into the road surface hole is carried out in stages. First, compressed air is blown into and around the hole. Next, the hole is flushed with a cleaning liquid. The emulsion is applied using Strassmayr’s Easy Patch system. This automatic electronic system matches emulsion quantities to the aggregates needed to repair the road surface, optimising quality.

The aggregate bin, whether, of whether 4m3 or 6m3 capacity, is divided into two sections to allow for two sizes of aggregate stone. Each bin section has its own hydraulic screw conveyor to deliver aggregate to the road surface. There is also a manually operated cover to protect the contents in the case of rain.

The 2,000litre emulsion bin is integrated into the body of the vehicle and is insulated with rockwool. A Riello diesel burner heats the emulsion and automatically controls temperature.

The working arm in the front of the vehicle has an operational radius of 3.5-4m. A ring of small nozzles at the end of the boom ensures the mixing of emulsion and aggregate.

The speed of delivery of the aggregates can be reduced if there is spillover outside the target area on the road surface during repairs, reducing waste. To maintain emulsion temperature, there is a preheating system for the pump body. This avoids temperature drops in the emulsion as the repair work starts and the first amounts of emulsion pass through the pump.

No crane is required to lift the pothole package off the truck chassis as it can be raised by six legs built into the system. Strassmayr has also incorporated an electrically operated 200litre water-spraying unit. A water nozzle at the end of the boom can be used for filling buckets or even washing. Spray bars in each aggregate bin section allow cleaning of the holding units.