Fast, efficient and long-lasting repairs are claimed for the heating system developed by the Nu-Phalt Group

Developed in the UK, the innovative

The company has been active in the heating sector for many years but used technology from another industry to bring a fresh approach to road repairs. Robert Muir, sales director of the Nu-Phalt Group said, “Our core business was building domestic heaters.”

Other heating systems used in road repairs produce heat from burners that then radiates into the ground. However Muir claimed, “These are quite inefficient and can overheat the surface so they can damage the material you want to recycle.”

Rather than operating continuously, the burner switches on and off continuously and it is this feature that prevents the surface from becoming overheated and which also allows heat to penetrate into the material. Muir said, “In each minute the unit is pulsing off and on. It might be on for 50 seconds and off for 10. You’re giving that time to rest and force the heat down.”

Muir said that tests have shown the equipment achieves effective heat penetration of the wearing course, “The heat gets down to the floor of the wearing course.”

Because the system is efficient and operates at a comparatively low heat, it is said to be safer and can also be used with more sensitive material types. Muir said, “This heater’s approved to work with surface dressing.” He added that for a more heat sensitive surface dressing, the heating cycle can be adjusted easily to a 30 second burn with 30 seconds off.

Another important key to the Nu-Phalt equipment is the use of a metallic woven fabric in the design of the burner. The metallic woven fabric is the crucial difference between the Nu-Phalt burner and rival equipment. This diffuses the flame and combined with the adjustable pulsed heat cycle, offers improved efficiency. Muir pointed out that earlier generation burners will heat the surface and can even set the binder on fire. He said, “This product allows you to get heat penetration of the wearing course.

The company claims that the high efficiency reduces working time, allowing a fixed heating cycle of just eight minutes compared with up to 50 minutes for some competing units. The unit’s efficiency means that the metal cover is merely warm to the touch during operation, increasing safety for the road crew by minimising the risk of burn injuries. Muir said, “The energy we’re turning into heat goes where it’s meant to go. Because you’re containing the energy, it reduces the heating cycle. When that heat is off, it’s off. It’s part of the process of controlling the heat so you’re not just heating the surface.”

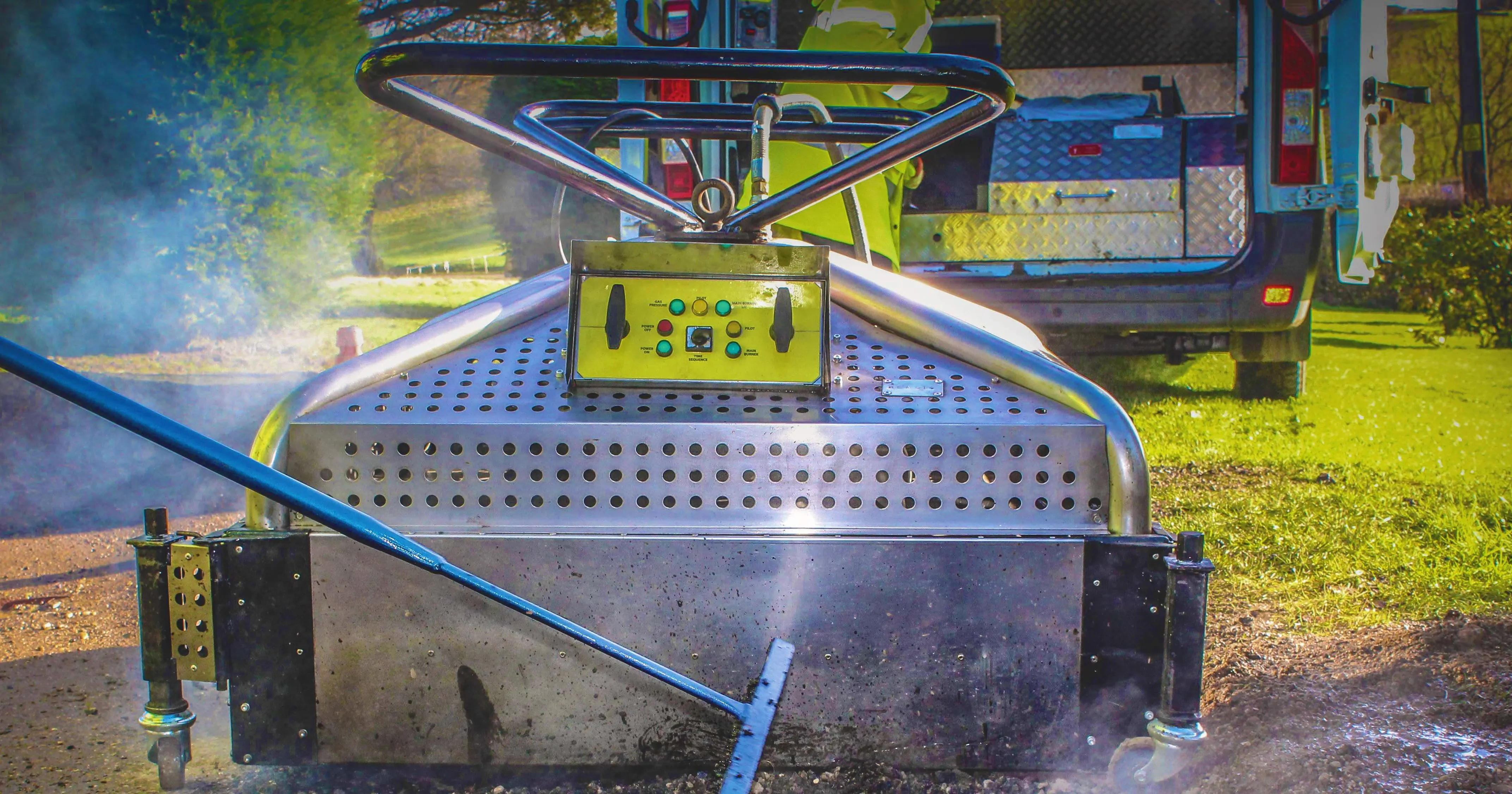

The heater units have holes in the top that draw in air. Muir said, “It goes through baffles that mix the air and gas and you have a very efficient and controllable heat source.”

Safety is another important factor with this equipment. The design of the heating unit, with the flames diffused by the woven material and the cover close to the surface, also boosts safety as no flames can escape. The gas pipe that connects the unit to the LPG cylinder in the vehicle is sheathed for safety while the unit also uses the vehicle's standard 12V supply. Another safety device is an emergency stop system in the vehicle that immediately stops the gas supply to the burner if required. The burner temperature is 650°C when the unit is working but woven material also loses its heat rapidly and just five seconds after being turned off, is merely warm to the touch.

Because the heat being generated is directed and enclosed, Muir said that the equipment can be used all year round, even in low temperatures. Adjustments to the control unit can compensate for low ambient temperatures and he added, “In Derby they did repairs at -10°C.”

All the equipment fits inside a single standard van, which also has a hotbox that can carry up to 50kg of materials.

The road crew switches on the hotbox heater when setting out in the van at the start of a shift and it quickly reaches the necessary temperature. Muir said, “Because you’re recycling the material in the road, the hotbox material is just for topping-up.”

The hotbox can be topped-up if necessary also by bagged material carried inside the van, which has room for 14-16 bags. And Muir added that the mix of the bagged material for the hotbox did require some research. “We spent two years developing it with Colas.

In general, one bag will fill two potholes.”

A heavy lifting hoist with an extending boom is fitted inside the truck, which allows the road crew to quickly move the burner out for use, and also pack the unit away afterwards. This lifting system can also be used to unload and load the compaction equipment from the vehicle, avoiding the risk of strain injuries for the road crew.

The equipment is easy to use and once the area to be repaired has been heated it can be scarified. An ionic, water-based binder is then poured on top and extra material can be added from the hotbox as required, followed by compaction. Muir said, “You’re looking at 25 minutes to do a repair from turning up onsite and you can do 20-25m2 of repairs/day. It’s one of the solutions that gives a cost-effective answer to traditional repairs.”

The standard unit features a 1x1m burner, although the company can supply a 2x1m unit as well for larger repairs. Muir added, “We also have a 2x0.5m unit which is perfect for joint failures.” This latter type is being used on the busy M40 motorway in the UK for repair work.

The system all packs inside a single van with a crew of two, offering lower running costs than other heating units that may require more vehicles and a bigger team. Muir added, “This system delivers sustainability targets.”

Because the system is sparing with materials, this cuts materials costs by around 25% compared with other patching systems. In addition, there is no need to go to a quarry to refill the material as the bagged products are sufficient and there is little disturbance in operation as there is no need to use a jackhammer. The burner itself is quiet and the only other site noise during a repair job comes from the compactor, a conventional pedestrian-operated single drum unit.

The firm has around 30 units in use in the UK and also has exported equipment to India, Australia, South Africa, the USA and Hungary, with the most recently having been delivered to Estonia as well as plans in store for other sales within Europe.