A Brazilian extraction operation is using a Rammer 3288 hydraulic hammer in a secondary breaking application The unit is helping maximise production at a facility in Brumadinho. The 2.04tonne hydraulic hammer is being used to increase the production of Itabirite at the FLAPA Mining site. Part of the Top Mix Group, the company operates in the heavy construction, dredging, mining, assembly and operation of processing and ore crushing plants.

At the company’s Fábrica Mine, Jangada Mine, Capão Xavier Mine

June 10, 2015

Read time: 2 mins

A Brazilian extraction operation is using a 5076 Rammer 3288 hydraulic hammer in a secondary breaking application The unit is helping maximise production at a facility in Brumadinho. The 2.04tonne hydraulic hammer is being used to increase the production of Itabirite at the FLAPA Mining site. Part of the Top Mix Group, the company operates in the heavy construction, dredging, mining, assembly and operation of processing and ore crushing plants.

At the company’s Fábrica Mine, Jangada Mine, Capão Xavier Mine, and Capitão do Mato Mine, which are all operated by main contractor5926 Vale, this quest for innovation and efficiency led to the purchase of the Rammer 3288 to break up oversized material prior to crushing and processing. “The iron ore is extracted from the mine primarily using explosives,” explained general manager Paulo Thiago Miranda. “Any oversized material that is too large for the crusher is broken again using the Rammer 3288.”

Miranda also said that the Rammer hammer represented a significant investment, but that his company was willing to pay a premium. "We consider Rammer a premium brand. It is a bigger financial investment, but we have fewer maintenance problems and a marked gain in production. Also, it has the credibility of the325 Sandvik name behind it.” With the relatively remote location of the mine and its dependence upon the reliability of the Rammer unit, FLAPA is reliant upon the aftersales support provided by local Rammer dealer, Rock Brit.

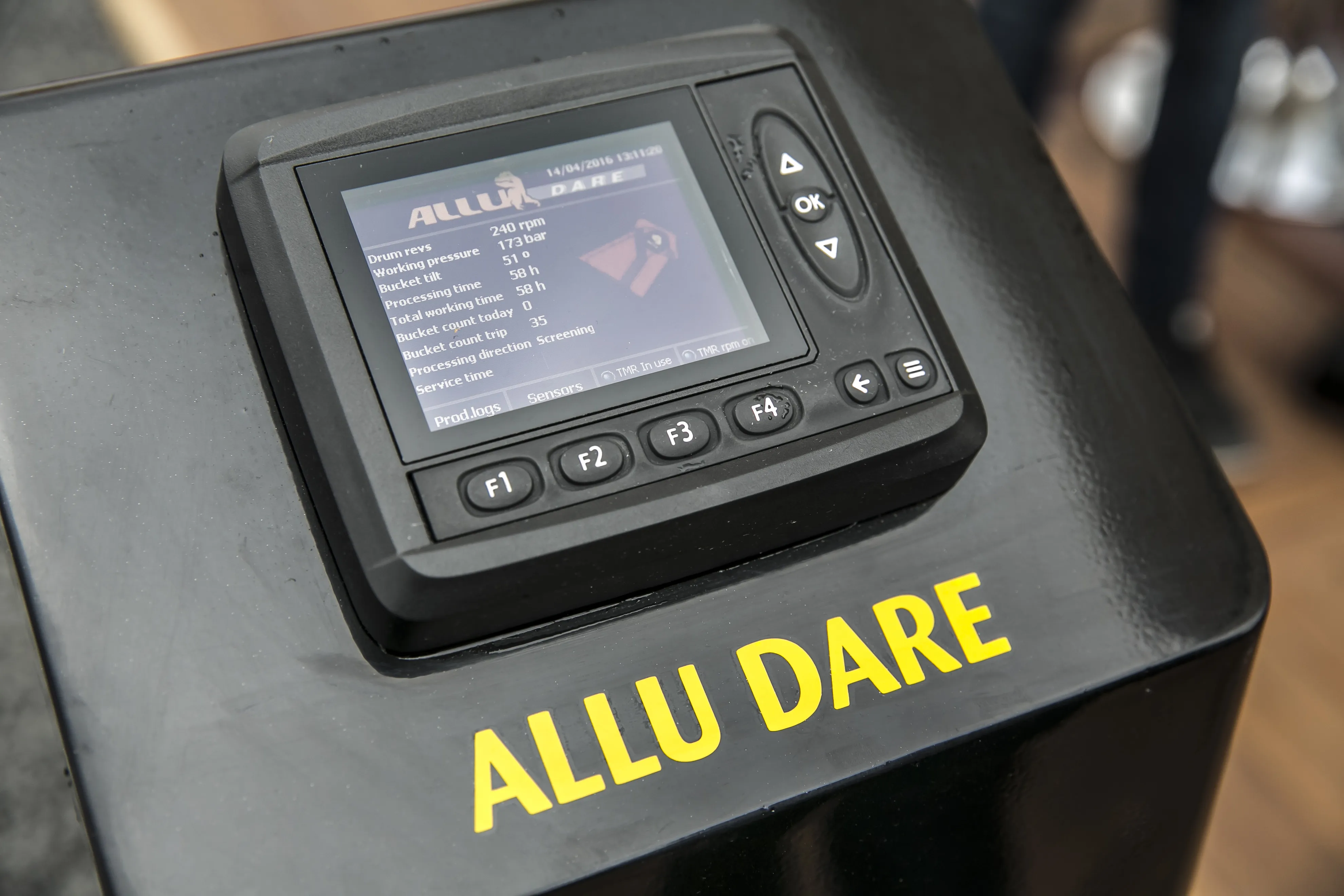

“Despite the tough working environment and long working hours in dusty conditions, the hammer has stood up well. In the first seven months of operation, we have had to order no parts. On the one occasion that it was sent to Rock Brit, it was only for washing and reading of the Ramdata diagnostic information,” commented Paulo Thiago Miranda.

At the company’s Fábrica Mine, Jangada Mine, Capão Xavier Mine, and Capitão do Mato Mine, which are all operated by main contractor

Miranda also said that the Rammer hammer represented a significant investment, but that his company was willing to pay a premium. "We consider Rammer a premium brand. It is a bigger financial investment, but we have fewer maintenance problems and a marked gain in production. Also, it has the credibility of the

“Despite the tough working environment and long working hours in dusty conditions, the hammer has stood up well. In the first seven months of operation, we have had to order no parts. On the one occasion that it was sent to Rock Brit, it was only for washing and reading of the Ramdata diagnostic information,” commented Paulo Thiago Miranda.