Tensar is making some key moves internationally, as well as in terms of market segments. The company is now marketing the GlasGrid range in the US and expects to develop healthy sales, however it sees major growth potential with the Geogrid product range. Jim Penman, director for bi-axial products & applications said: "One area we're moving into is base reinforcement and in particular what we're looking at is mechanistic emirical (ME) technology." Tensar has worked with the University of Illinois on a new d

April 10, 2012

Read time: 2 mins

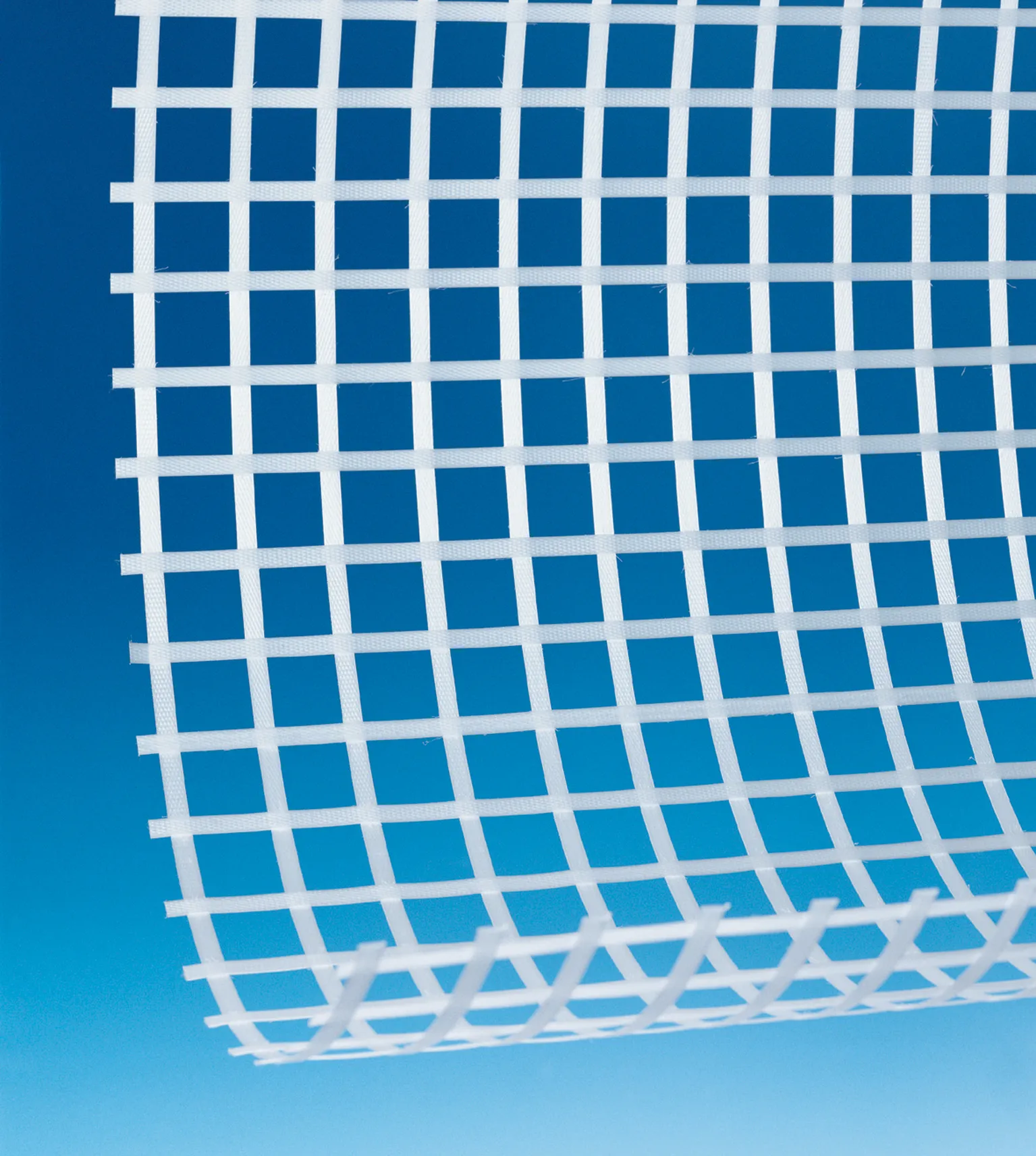

RSS340 Tensar has worked with the University of Illinois on a new design specification for Geogrid, setting out numerical models. Discrete element modelling using spheres has also been employed to establish the behaviour of the materials in a construction environment. With previous attempts in this field, there was no interaction between the models and the results were limited. However this latest advance allows the engineers to model the load exerted on the road and as a result, the effect of the GlasGrid product can be factored into the calculations.

With this stage complete, Penman said that the company is now starting to develop the product commercially and he also outlined the commerical benefits to Tensar of proving the Geogrid in the base reinforcement sector. "Right now our market is in soil reinforcement buth the market for base reinforcement is 50 times the size," he said.

Tensar is making some key moves internationally, as well as in terms of market segments. The company is now marketing the GlasGrid range in the US and expects to develop healthy sales, however it sees major growth potential with the Geogrid product range.

Jim Penman, director for bi-axial products & applications said: "One area we're moving into is base reinforcement and in particular what we're looking at is mechanistic emirical (ME) technology."With this stage complete, Penman said that the company is now starting to develop the product commercially and he also outlined the commerical benefits to Tensar of proving the Geogrid in the base reinforcement sector. "Right now our market is in soil reinforcement buth the market for base reinforcement is 50 times the size," he said.