Controls says that the continuous search for new technological solutions has led Wykeham Farrance to an important threshold which shows how well-directed research investment can result in technological successes both in terms of quality and price.

February 6, 2012

Read time: 2 mins

"Wykeham Farrance, the Soil Mechanics Division of Italian materials testing equipment manufacturer, Controls, has always worked closely with universities and research centres in sharing ideas and developing technologies that can be industrialised in the field of stringent quality control and reliability, which are now well recognised as the basis for successful development," says Controls.

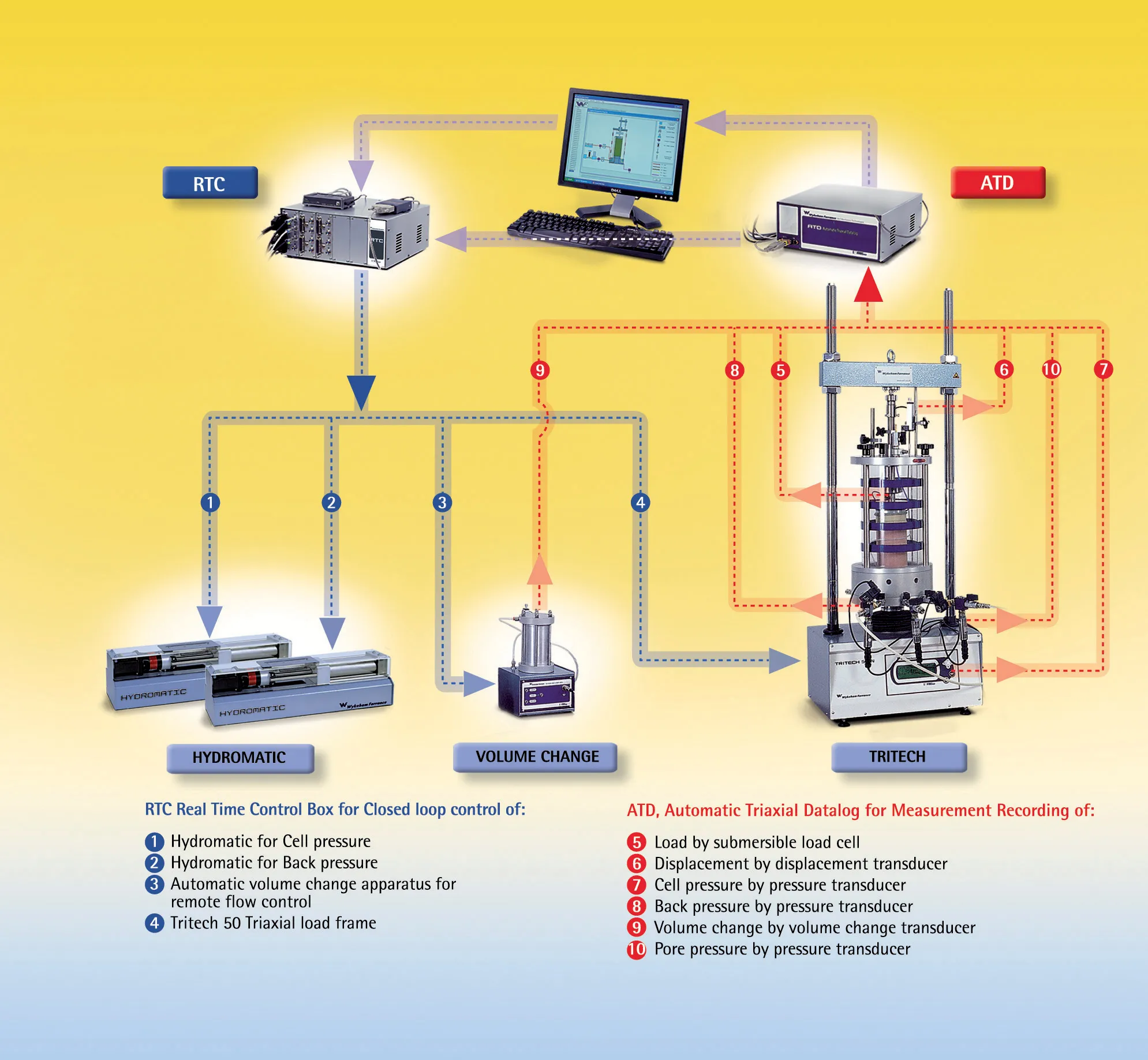

Among the pioneers in the application of automation for geotechnical apparatus, Wykeham Farrance's automatic equipment is said to allow full compliance with international standards; the exclusion of user errors and to avoid discrepancies due to non-calibrated instruments or testing interruptions at the end of the working day.

"Above all, laboratory productivity is highly increased with a consequent reduction of costs," says Controls, which was highlighting this automation at the Geofluid Exhibition and Conference in Piacenza, Italy (6-9 October, 2010).

Among products are Shearmatic (for direct/residual shear tests); Autotriax (static triaxial tests, effective stress, stress path, permeability and unsaturated soil testing), and Dynatriax (dynamic triaxial testing and a combined resonant column/cyclic torsional shear apparatus).

"These allow the user to set all the test parameters beforehand.

Dynatriax, the automatic dynamic triaxial system, represents the new generation of dynamic systems.