A Simex PL 2000 cold planer was recently seen manouevering around the narrow streets of the Tuscan capital Florence in northern Italy. The project involved resurfacing the wearing course at a depth of 30mm, explains Andrea Palmerani, owner of contractor Bitumvie.

“We needed equipment that would guarantee us a large milling surface all the while remaining in the field of compact machines suitable for a city context,” he said. “The 2m-wide drum immediately attracted my attention.”

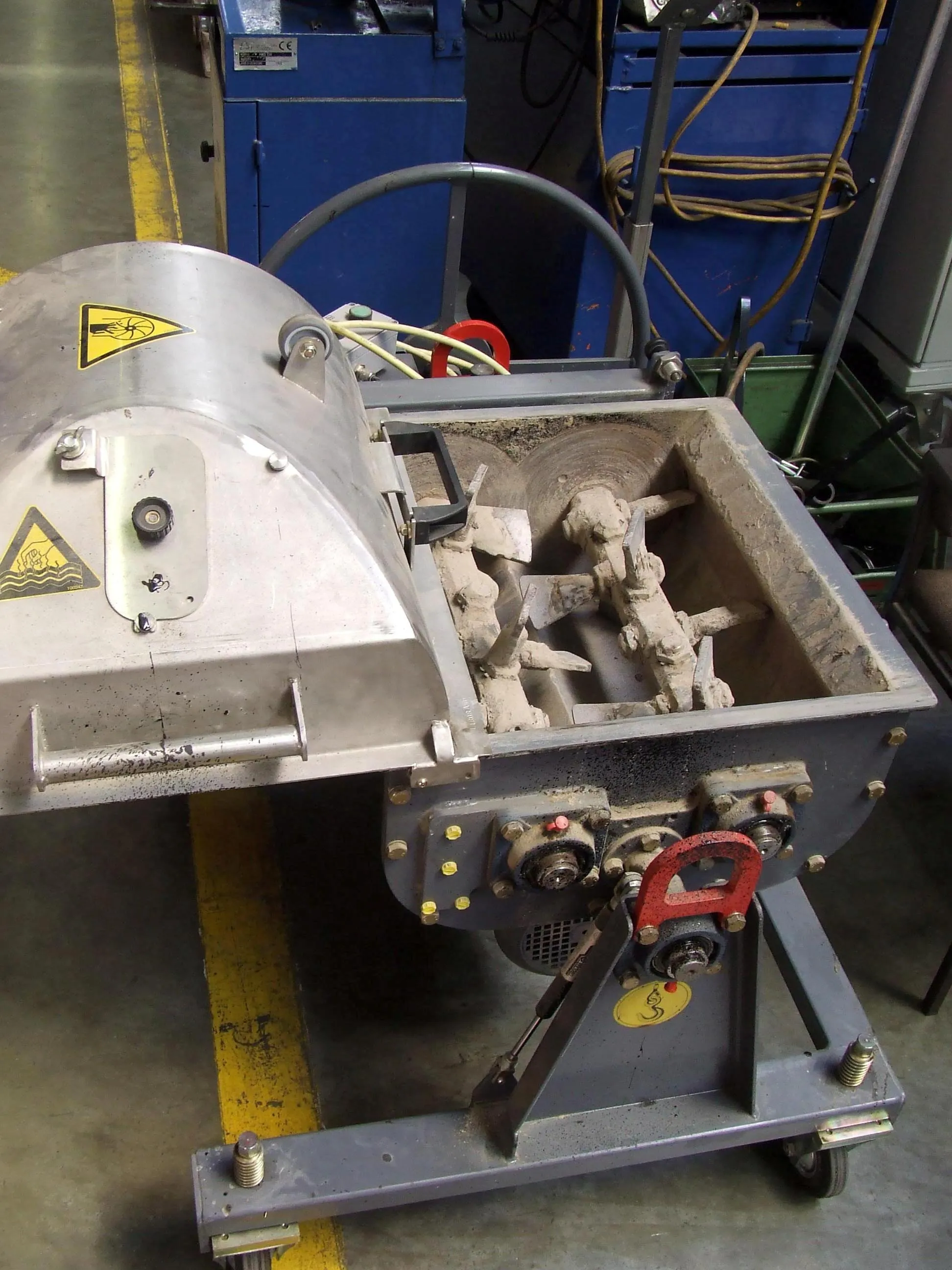

The PL 2000 can be considered the big sister among Simex’s asphalt planers of the 1000-1200-1500 series, specially designed for scarifying the road surface course. Importantly, speed and efficiency are hallmarks of the series in order to reduce construction time, especially important for narrow, heavily trafficked inner European roads. This led to the creation of a model equipped with a 2m-wide milling drum.

The PL 2000 is designed to be coupled to the latest generation SSL - characterised by high hydraulic power - and benefits from all the Simex features that make the difference on site. Bitumvie coupled the PL 2000 to a Bobcat T86 skid steer loader, the flagship of the Bobcat line of compact tracked loaders. The Super Flow function guarantees an oil flow of 155 litres/min, ideal for equipment such as the PL 2000 which requires a very powerful base machine to obtain the productivity required on site.

The T86 is the ideal machine to push the PL 2000 because it combines high power with an improved lifting capacity. In addition, the electronic speed set-up allows a gradual and progressive advancement, which is a huge benefit for milling activitie.

Bitumvie recorded an average advancement speed between 10 and 15 linear metres/min, with a milling depth set at 30mm.