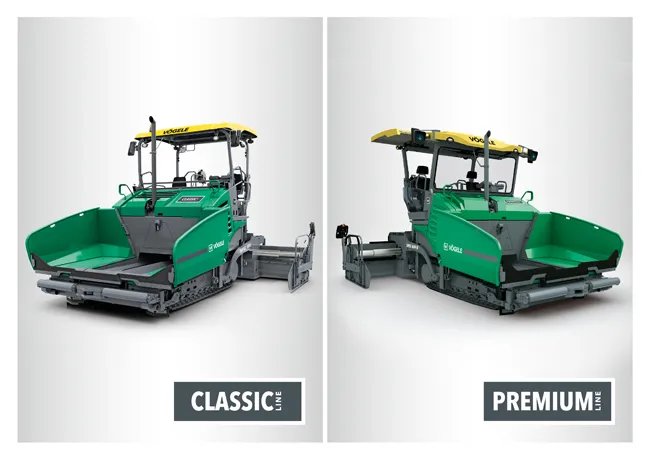

The new Classic Line is for pavers equipped with the firm’s own, easy-to-use, ErgoBasic operating concept. These machines benefit from solid construction and quality components and a basic range of operating features. However, these machines offer all the key features required for productive paving work.

The firm says that its Classic Line machines are equipped with engines and screeds that match the national requirements of their respective target markets.

At the same time,

The display also provides the operator with extensive machine and operating information. Data concerning the screed, conveyors and augers can be quickly called up and settings can be changed as required. The automatic programs of Vögele 's AutoSet Plus package are also operated using the display of the ErgoPlus 3 console. If a customer has opted to use the RoadScan temperature measurement system, the paver operator can monitor the temperature of the asphalt being paved on the display.

Customers using the sophisticated WITOS Paving process management solution developed by

The firm’s Premium and Classic Lines are further divided into up to five different classes: Mini Class, Compact Class, Universal Class, Highway Class and Special Class. The current total of 48 machines and 26 screed versions offered by Vögele are allocated to one of the lines based on their operating concept and equipment as well as to one of the classes depending on their pave width, performance and areas of application.

Vögele plans to unveil the latest machines in the Classic Line and the Premium Line at the bauma 2019 exhibition in Germany.