AN INNOVATIVE wet steel shotblasting machine developed by pavement re-texturing specialist Klaruw is now being tested in the UK.

February 6, 2012

Read time: 3 mins

AN INNOVATIVE wet steel shotblasting machine developed by pavement re-texturing specialist 2311 Klaruw is now being tested in the UK. The prototype machine is designed for wet application shot blasting, a technique intended to improve roadway macro-texture and micro-texture to safe levels. The machine was developed by Dutch firm Klaruw Tilburg and features computercontrolled Macrotex (MAT) shot-blasting. This equipment is said to offer advantages in process control, versatility of treatment and production rate over conventional shotblasting machines. As it uses wet steel shot, it allows retexturing to be carried out even in heavy rain, unlike conventional dry methods.

The MAT process has been developed to improve the macro-texture of most natural aggregate surfaces, a technique that helps surface water to escape and prevent aqua-planing. Although the process primarily works on macro-texture, improvement in micro-texture is a secondary benefit and this boosts surface friction and provides wet weather skid resistance.

Two separate night-time trials were carried out on sections of concrete, hot rolled asphalt (HRA) and thin surfacing on the M56 near Chester.2312 North Wales Trunk Road Agency (NWRTA) is also looking at results from HRA (hot rolled asphalt) and thin surfacing after trials on the A55 North Wales Coast Road.

According to NWTRA, the MAT shot blasting process has provided a rapid, single pass and non-weather dependent process for the improvement of the macro-texture of surface courses, with minimal disruption to the road network.

A-one+ (a highway services joint venture company formed between2320 Halcrow Group Limited, 184 Colas and 2319 Costain) made similar comments about the benefits of improved water dispersion and wet weather skid resistance using this technology. Both agencies are now assessing the results of the trials, with early indications that both saw promising improvements. Klaruw says it is confident that results will back up the findings of trials in Holland where significant improvements in macrotexture have been observed on asphaltic concrete runways.

The MAT shot-blasting process has also been proven effective for removing bitumen residues left on newly laid porous asphalt to prevent socalled 'bitu-planing', and for cleaning the cementitious film off new concrete. The machine will be undergoing further tests on HRA, a surfacing system prevalent in the UK.

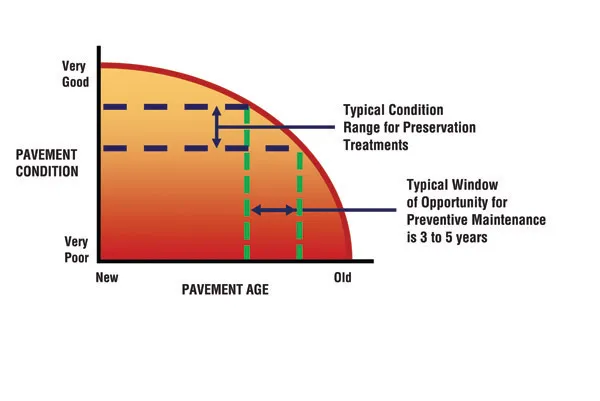

Klaruw believes that macrotexture rejuvenation using the MAT machine is set to provide a versatile, cost-effective and highly sustainable solution for addressing aqua-planing and wet skid issues. By reworking existing surfaces, it extends service life of structurally sound roads by several years before more costly, disruptive overlay or inlay is needed. The MAT machine shot blasts and cleans the road surface as one integral unit in one pass, simplifying traffic management and leaving treated sections ready for use immediately. The technique requires no aftertreatment or curing time, and leaves no residual deposits.

MAT retexturing also has significant environmental benefits. It applies no new material, produces minimal waste, and recycles water and shot used in the process, reducing reliance on new materials and landfill.

The main MAT shot-blast vehicle incorporates a steel shot storage and recycling unit, a rear tank for waste water and debris, with the shot-blasting mechanism housed in between.

Used shot is reprocessed in the shot storage unit while the remaining water-borne material is conveyed to a closely coupled, dedicated water cleaning machine (WCM) behind the MAT unit. This cleans and recycles water for re-use in the shot-blasting treatment, while processing residues to an almost dry condition for disposal.

The new MAT unit can treat widths ranging from 24-190cm.

Working speed is variable, ranging from 3m/minute for heavy duty retexturing, up to 100m/minute for light cleaning.

Depending on pavement type and condition, and application requirements, the machine will generally treat around 1,300- 3000m2 of pavement/hour, or from 3-7km/day.

The MAT process has been developed to improve the macro-texture of most natural aggregate surfaces, a technique that helps surface water to escape and prevent aqua-planing. Although the process primarily works on macro-texture, improvement in micro-texture is a secondary benefit and this boosts surface friction and provides wet weather skid resistance.

Two separate night-time trials were carried out on sections of concrete, hot rolled asphalt (HRA) and thin surfacing on the M56 near Chester.

According to NWTRA, the MAT shot blasting process has provided a rapid, single pass and non-weather dependent process for the improvement of the macro-texture of surface courses, with minimal disruption to the road network.

A-one+ (a highway services joint venture company formed between

The MAT shot-blasting process has also been proven effective for removing bitumen residues left on newly laid porous asphalt to prevent socalled 'bitu-planing', and for cleaning the cementitious film off new concrete. The machine will be undergoing further tests on HRA, a surfacing system prevalent in the UK.

Klaruw believes that macrotexture rejuvenation using the MAT machine is set to provide a versatile, cost-effective and highly sustainable solution for addressing aqua-planing and wet skid issues. By reworking existing surfaces, it extends service life of structurally sound roads by several years before more costly, disruptive overlay or inlay is needed. The MAT machine shot blasts and cleans the road surface as one integral unit in one pass, simplifying traffic management and leaving treated sections ready for use immediately. The technique requires no aftertreatment or curing time, and leaves no residual deposits.

MAT retexturing also has significant environmental benefits. It applies no new material, produces minimal waste, and recycles water and shot used in the process, reducing reliance on new materials and landfill.

The main MAT shot-blast vehicle incorporates a steel shot storage and recycling unit, a rear tank for waste water and debris, with the shot-blasting mechanism housed in between.

Used shot is reprocessed in the shot storage unit while the remaining water-borne material is conveyed to a closely coupled, dedicated water cleaning machine (WCM) behind the MAT unit. This cleans and recycles water for re-use in the shot-blasting treatment, while processing residues to an almost dry condition for disposal.

The new MAT unit can treat widths ranging from 24-190cm.

Working speed is variable, ranging from 3m/minute for heavy duty retexturing, up to 100m/minute for light cleaning.

Depending on pavement type and condition, and application requirements, the machine will generally treat around 1,300- 3000m2 of pavement/hour, or from 3-7km/day.