A new online concrete pavement design tool has been launched in the US by three major cement and concrete organisations.

PavementDesigner.org – available free of charge - was created for city, county, and consultant engineers as well as academics and anyone involved in design of roadway, industrial, and parking area pavements. PavementDesigner improves upon traditional pavement design software programs, according to its creators.

The platform is being offered completely free of charge by the American Concrete Pavement Association, the National Ready Mixed Concrete Association and the Portland Cement Association.

PavementDesigner eliminates the expense and burden of ordering software as well as updates and licenses. The platform brings the industry’s best pavement design programs together into a single website that allows professionals to design pavements immediately.

Users have the option of creating a user ID and password to save their design work, as well as to retrieve projects using any digital device. The online system is also automatically updated when new content or details are added. Users will not have to download updated software or “patches,” say the organisations.

“By bringing multiple programs together in one package and eliminating the cost and time to download software, updates and patches, we have removed barriers and enabled designers to select the best option for pavement designs,” said Eric Ferrebee, director of technical services at the American Concrete Pavement Association.

“This comprehensive but easy-to-use pavement design tool not only covers full-depth concrete, but also provides design solutions for concrete overlays and composite pavements,” said Wayne Adaska, director of pavements at the Portland Cement Association. “The tool also includes other cement-based materials like roller-compacted concrete, cement-treated base and full-depth reclamation with cement.”

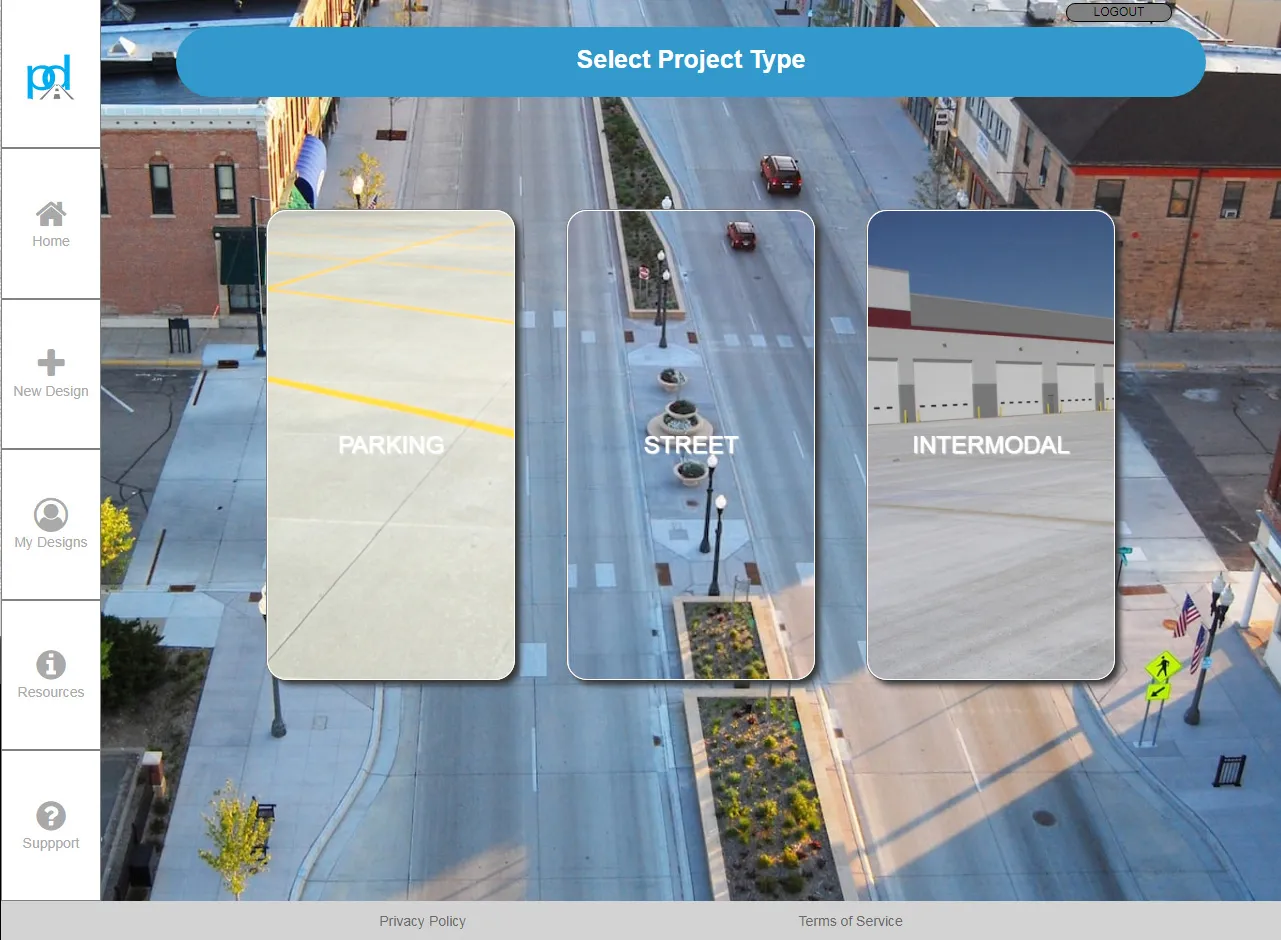

PavementDesigner guides the user through three basic stages of pavement design. The user first selects the project type, either parking, street or intermodal facility. The system then guides the user through the project level details and the design of the pavement structure.

Each module has help screens and conversions to assist the user in entering pavement structure details. After pavement structure information is entered and calculated, the user moves to a summary screen where the pavement design may be reviewed, analysed, printed and/or saved.

The portal also includes helpful resources, which are readily available from the sidebar. Users can view a PavementDesigner introductory video. They can view the platform’s map and methodology visual to see solutions and a process flow. They can also watch a video on how to use the portal to design a jointed plain concrete pavement.

A resource section includes details from drawings of various concrete pavement structures, as well as images, descriptions and weblinks to other resources and tools. Additional training and support materials will be added as feedback is received, according to the creators.

The American Concrete Pavement Association, founded in 1963, is the national trade association for the concrete pavement industry.

Founded in 1930, the National Ready Mixed Concrete Association is an industry advocate. Since 1991, the RMC Research & Education Foundation has been funding programmes to improve quality, sustainability and professionalism in the ready mixed concrete industry.

The Portland Cement Association, founded in 1916, is a policy, research, education and market intelligence organisation serving America’s cement manufacturers. PCA members represent 92% of US cement production capacity and have facilities in all 50 US states.