Winter repairs The tough winter conditions in Canada play havoc with road conditions and this often results in problems such as potholes and longitudinal cracking. But Aquadyne Industries says it has found a solution with the introduction of infrared asphalt restoration equipment. The equipment from Ray-Tech Infrared can be used all year round to repair roads and is now carrying out valuable work in Canada due to the firm's local agent, Aquadyne Industries. These units offer an alternative to the traditiona

February 15, 2012

Read time: 2 mins

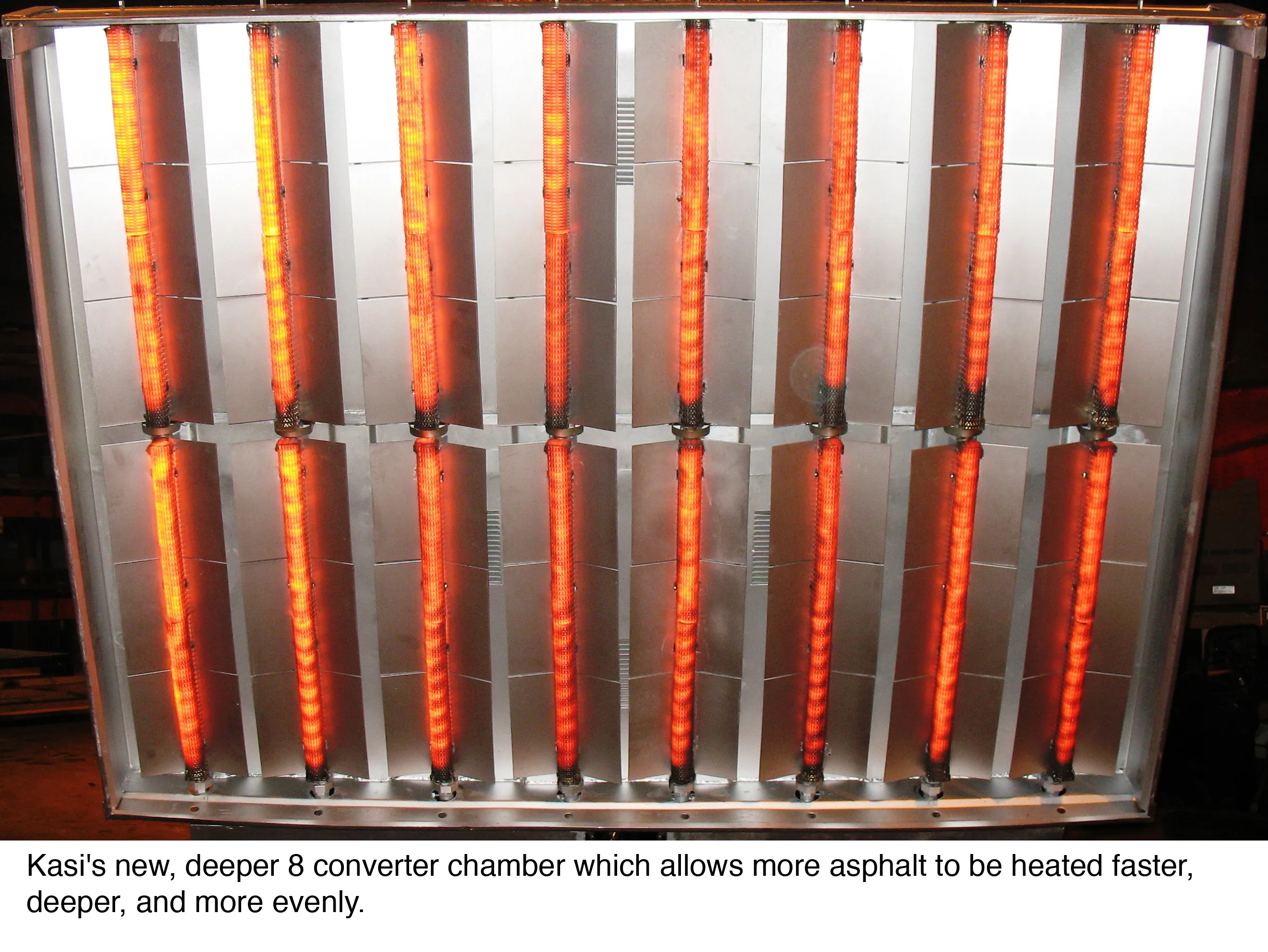

Winter repairs The tough winter conditions in Canada play havoc with road conditions and this often results in problems such as potholes and longitudinal cracking. But Aquadyne Industries says it has found a solution with the introduction of infrared asphalt restoration equipment. The equipment from Ray-Tech Infrared can be used all year round to repair roads and is now carrying out valuable work in Canada due to the firm's local agent, Aquadyne Industries. These units offer an alternative to the traditional cut and fill method of fixing potholes used in Canada. This normally involves a carbide-tipped saw cutting a square patch from around the damaged road area and an excavator then digs out the asphalt remains, with cold or hot asphalt mix rolled into the site. This repair is only temporary though as water eventually seeps into the seam, resulting in a failure.

The2692 Ray-Tech heaters penetrate and soften the existing road surface to around 80mm at 165°C. This ensures a good bond to the existing surface and a life expectancy as long as the surrounding pavement and depending on weather, the repair can be completed in 20 minutes.

The machines are said to be easy to use and compact, allowing them to be towed to site by small trucks.

Because of the cost and labour savings, Aquadyne Industries has already seen Canadian purchasers acquire lucrative maintenance contracts because of the unique Ray- Tech equipment according to the firm.

The

The machines are said to be easy to use and compact, allowing them to be towed to site by small trucks.

Because of the cost and labour savings, Aquadyne Industries has already seen Canadian purchasers acquire lucrative maintenance contracts because of the unique Ray- Tech equipment according to the firm.