Total has started a long-term test involving resurfacing a road section in England with its new Total Styrelf Long Life binder.

A section of dual carriageway in the county Northamptonshire is the first in the country to be resurfaced with Styrelf Long Life in an effort to increase the lifespan of roads and reduce the need for roadwork interventions, according to Total UK. The company said it is working with the government agency Highways England and the contractor Tarmac to resurface a busy section of the A43 near Silverstone with the new mix.

England’s motorways and major A-roads are expected to be resurfaced every 10-12 years because water ingress, UV exposure and oxidation cause the surface to deteriorate and crack. However, Total says that laboratory tests have shown that its Styrelf Long Life can protect the road surface from the elements so well that roads built with it could last for a longer period of time without the need for intervention.

Styrelf is designed to be more resistant to the elements by oxidising more slowly. This slows down the ageing process meaning that the road surface stays flexible for longer. Consequently, the binder’s initial performance characteristics, such as resistance to fatigue, fretting, and thermal cracking are retained for longer.

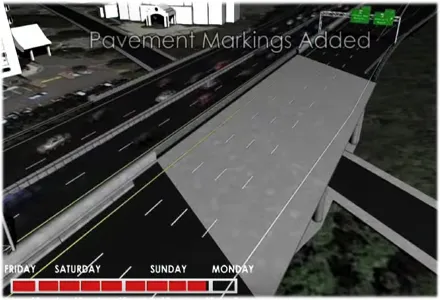

Three sections of the road have been surfaced, the first with a standard bitumen, the second with Total Styrelf eXtreme 100 and the third with Total Styrelf Long Life.

The trial could run for up to 15 years. Total UK’s experts will take samples from each section of the carriageway at regular intervals to measure the ageing performance and key characteristics of the bitumen and to understand the degradation caused by oxidation and UV exposure.

The new technology has previously been tested in the laboratories of Total and on sections of road in the Netherlands and Germany, but the A43 trial is the first time it has been used with such high traffic levels.

“What we have in this case is essentially an anti-ageing cream for roads,” said Brian Kent, technical director at Tarmac. “Just as these products are designed to reduce and prevent the signs of fine lines and overall ageing of the skin, the new bitumen being trialled on the A43 will protect the road surface. It not only has the potential to offer improved value for money to the public purse, but it also contains properties to increase the overall lifespan of roads. Through preventing cracks to the surface of the road caused by elements such as air and water, the longer life bitumen has the ability to reduce disruption, deliver long-term carbon savings and importantly help network operators to better manage their assets.”

“These long-life binders will contribute to achieving clients’ decarbonisation goals by reducing roadworks, saving manufacturing, transport and installation energy, and the associated emissions,” said Rick Ashton, market development manager at Total UK. “This trial paves the way for enhanced highways asset management and predictive deterioration modelling for Highways England.”

Total UK estimates that getting the asphalt required to resurface a mile (1.6km) of single-lane carriageway - not including transport to site– can produce up to 26.5 tonnes of CO2. If two resurfacing interventions could be avoided, the reduction in asphalt production alone could many tonnes of CO2.