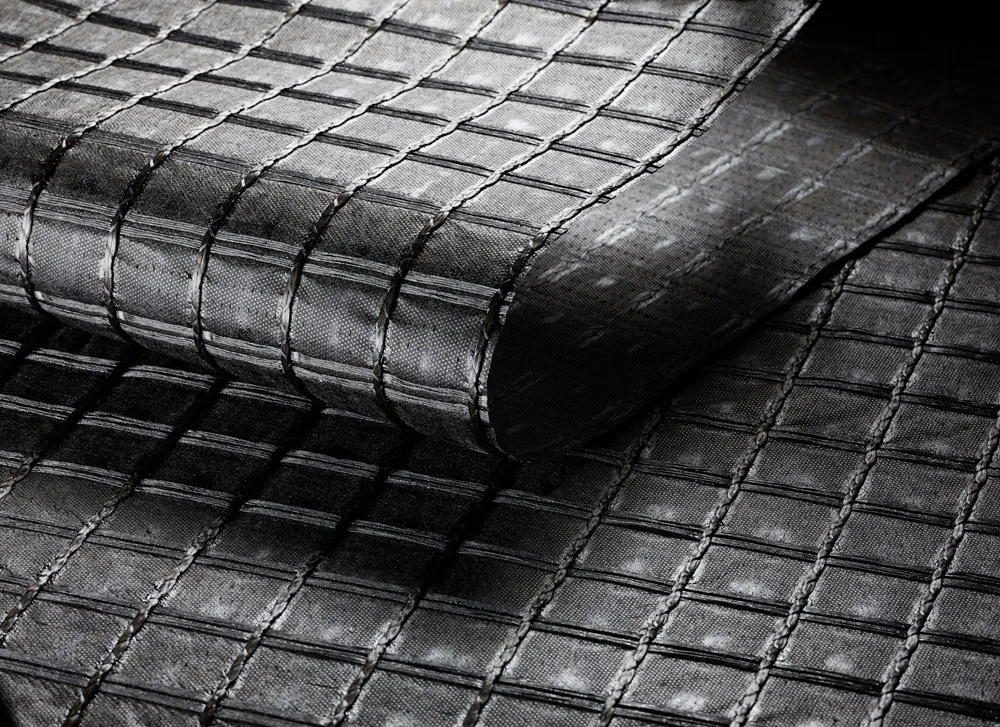

The proven HaTelit asphalt reinforcements suit use in road rehabilitation and are said to offer both sustainability and cost-effectiveness.

Conventional repair and rehabilitation work can be a quick, cost-effective solution but may not prevent reflective cracking, which then has to be repaired again.

According to Huesker, its HaTelit asphalt reinforcement system can tackle the issue, while also being quick and easy to install, helping minimise traffic disruption during repair works.

The firm says that its HaTelit product offers long-term durability due to the special bitumen coating (bitumen content > 65 %) and an optimal mesh size. This allows a strong adhesive bond with asphalt layers. Studies have shown that even 15 years after a repair has been carried out, the road is in a condition equivalent to that of a full reconstruction.

The extended service life, less use of material and transport not only have a positive impact on costs of up to 40%, but also reduce CO2 emissions per rehabilitated lane kilometre by more than 24.3tonnes.

In addition, the latest HaTelit asphalt reinforcement products are available for use on both asphalt and concrete surfaces. A particularly sustainable variant is HaTelit C eco, which consists of 100 % PET recycled yarn, while retaining the performance of the original HaTelit C iproduct.