The technology has meant that PAVETM system - for non-contact layer thickness measurement - is now competing in the finals against two other innovations in the

Moba says that PAVE-TM is the world‘s only system for automatic layer thickness measurement in road construction. The system constantly displays the thickness of the paved asphalt layer which reduces manual measurements.

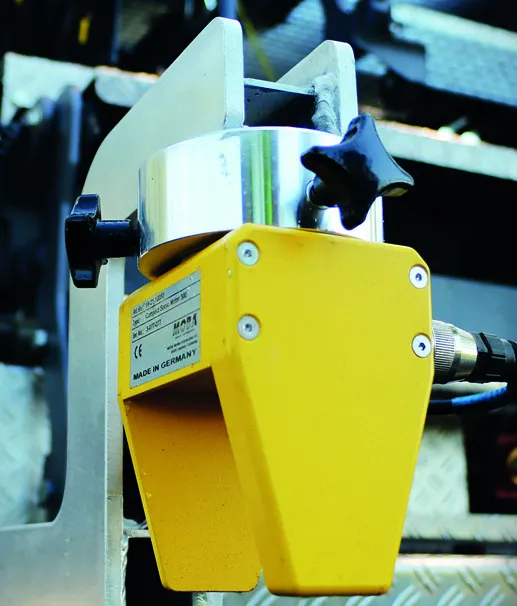

The new CSMT-300 ultrasonic sensor - developed in-house at MOBA specifically for thickness measurement - increases the accuracy of the system. The system reduces the amount of paving material and saves considerable costs.

Data collected by PAVE-TM can be incorporated into BIM – building information modelling – if it is being used by the contractors and client. This prepares the way for industry 4.0, the trend of automation and data exchange including cyber-physical systems, the Internet of things, cloud computing and cognitive computing. Industry 4.0 is commonly referred to as the fourth industrial revolution.