By Mike Woof

April 26, 2024

Read time: 1 min

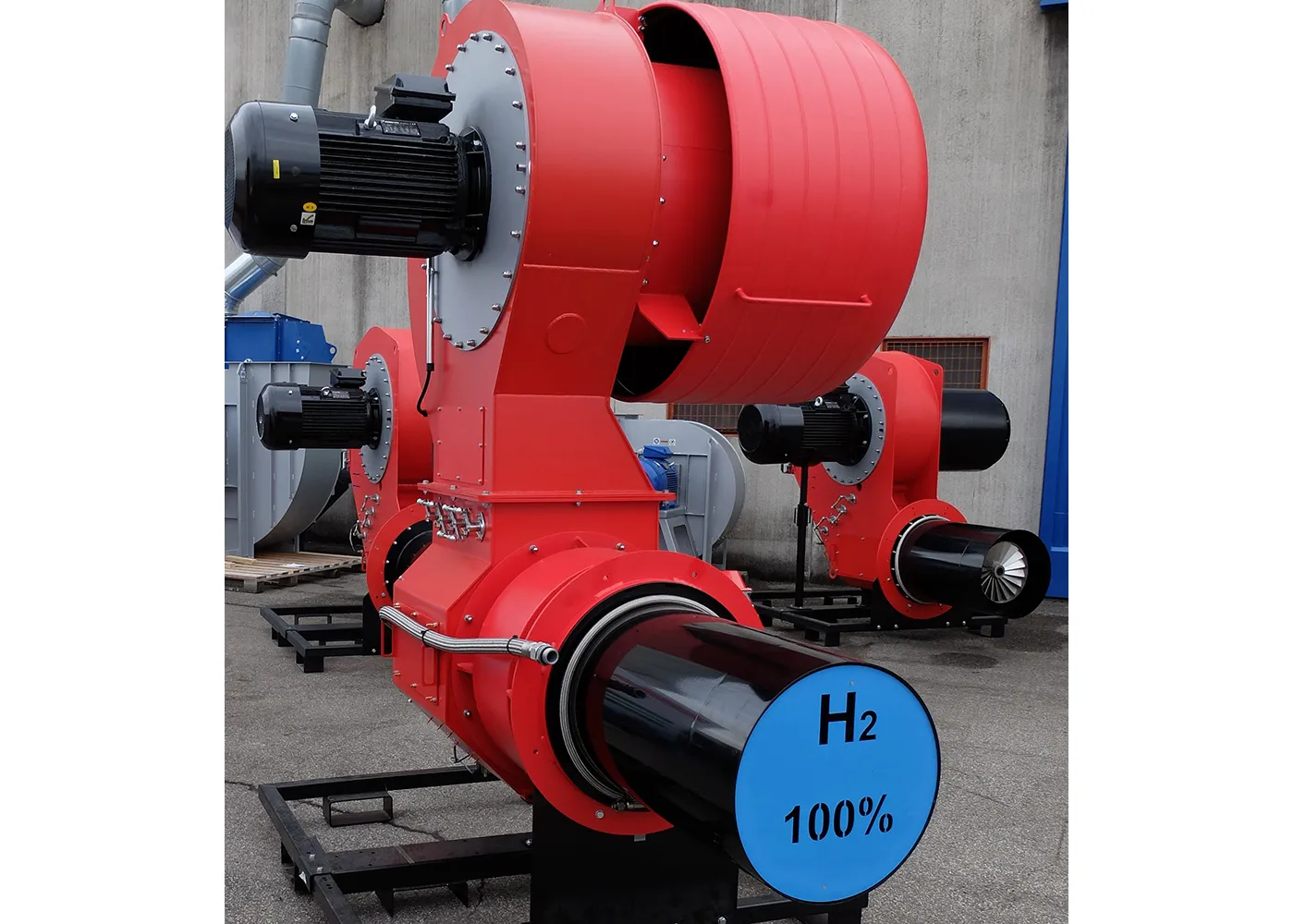

Marini’s efficient EvoDryer system is said to offer high efficiency and high quality for asphalt batching applications. The drum is now longer and the burner has been redesigned to ensure performance is maximised.

A key feature of the reconfigured design is with the reduction of blue smoke from the pugmill and discharge areas. This is now collected and filtered to minimise emissions.

Meanwhile, the air out of the drum is also filtered to reduce emissions. And the hot air is also recirculated into the drum, boosting efficiency and reducing fuel consumption. Recirculating the air also reduces the emissions from the plant, a major boost for environmental performance.