Improved infrared asphalt repair technology is speeding pothole repairs in applications in North America.

April 4, 2012

Read time: 2 mins

Improved infrared asphalt repair technology is speeding pothole repairs in applications in North America.

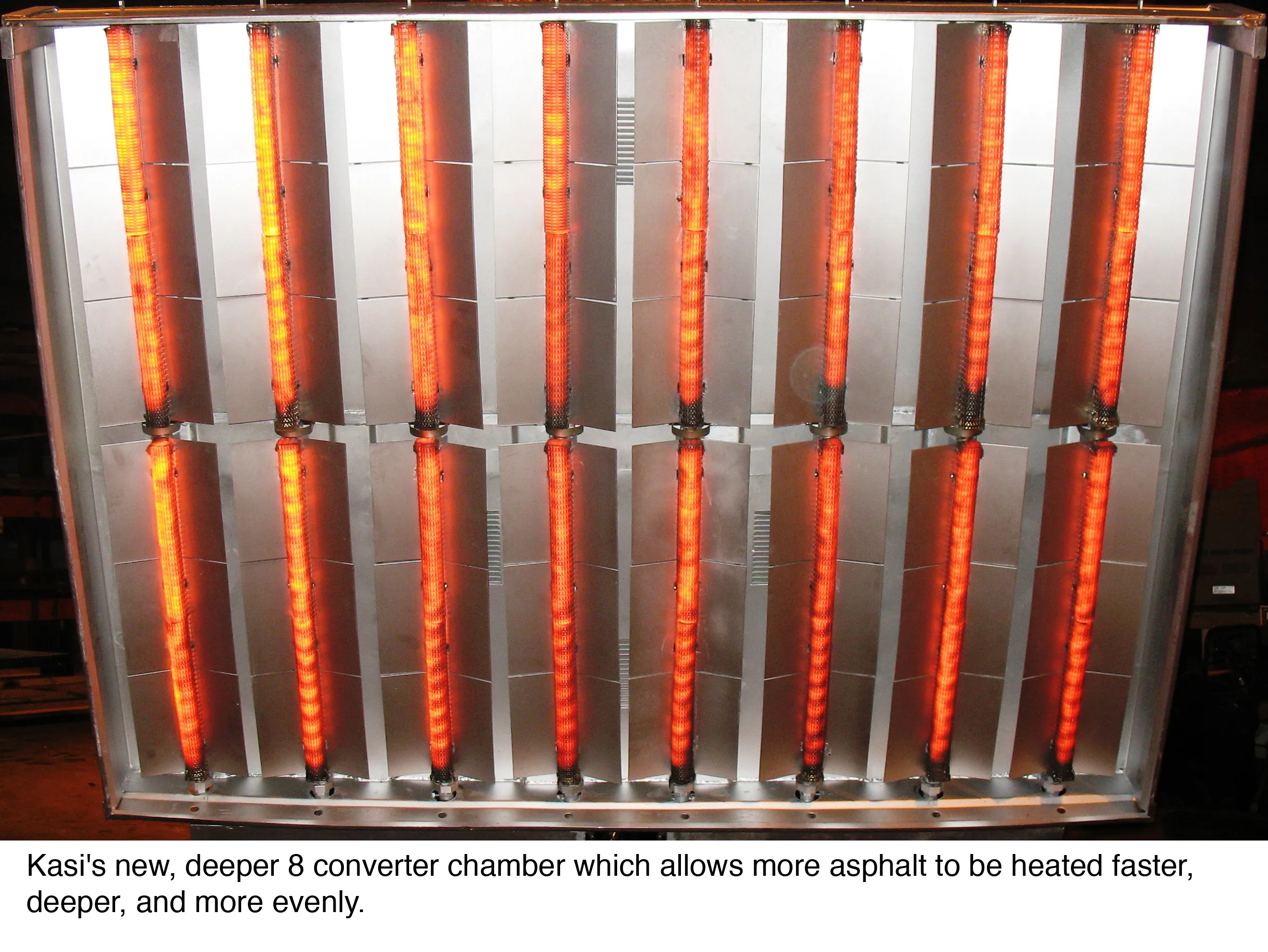

Specialist2428 Kasi Infrared has had numerous successes with local authorities which use the equipment to deliver seamless infrared asphalt repairs in less than 20 minutes. This method is said to be achieved at a fraction of the cost for conventional remove and replace techniques. Asphalt Technology, a California-based company is using the Kasi equipment to deal with failures caused by water intrusion. Using the equipment makes considerable savings over conventional remove and replace methods. Asphalt Technology opted for a new upgraded infrared asphalt repair option from Kasi. The infrared chamber upgrade enables seamless asphalt repair in under 20 minutes and doubles infrared chamber longevity to over 10 years. A key feature is a new, deeper 8 converter chamber which allows more asphalt to be heated faster, deeper, and more evenly. The contractor transports the equipment in Kasi’s Minute Man trailer-mounted system, which has an asphalt reclaimer to keeps the material at plant mix temperature. Unlike traditional saw, cut, and remove or crack filler repair techniques, Kasi’s infrared system leaves no seams for water and ice to penetrate and patches should last twice as long. The infrared repair’s continuous surface also eliminates the need for tack-coating the edges, boosts durability, and allows roads to be opened to traffic immediately. Lab studies show there is no change in asphalt integrity from the use of its infrared equipment according to Kasi.

Specialist