Huesker’s Tektoseal is said to be a high-performance sealing for groundwater protection, contaminated site remediation and hydraulic engineering. Geosynthetic clay liners (GCL) have been successfully used for many years as a natural sealing option for groundwater protection, contaminated site remediation, landfill construction, hydraulic engineering and road construction applications.

November 11, 2013

Read time: 2 mins

Geosynthetic clay liners (GCL) have been successfully used for many years as a natural sealing option for groundwater protection, contaminated site remediation, landfill construction, hydraulic engineering and road construction applications.

The continuing development of industrially manufactured bentonite sealing systems is said to have culminated in the new Tektoseal product. Building on Huesker's long and successful track record in sealing projects with NaBento (stitched bentonite composite), Tektoseal is a further intelligent composite liner, which is said to boast an improved internal angle of friction, increased shear strength and optimised outer friction properties.

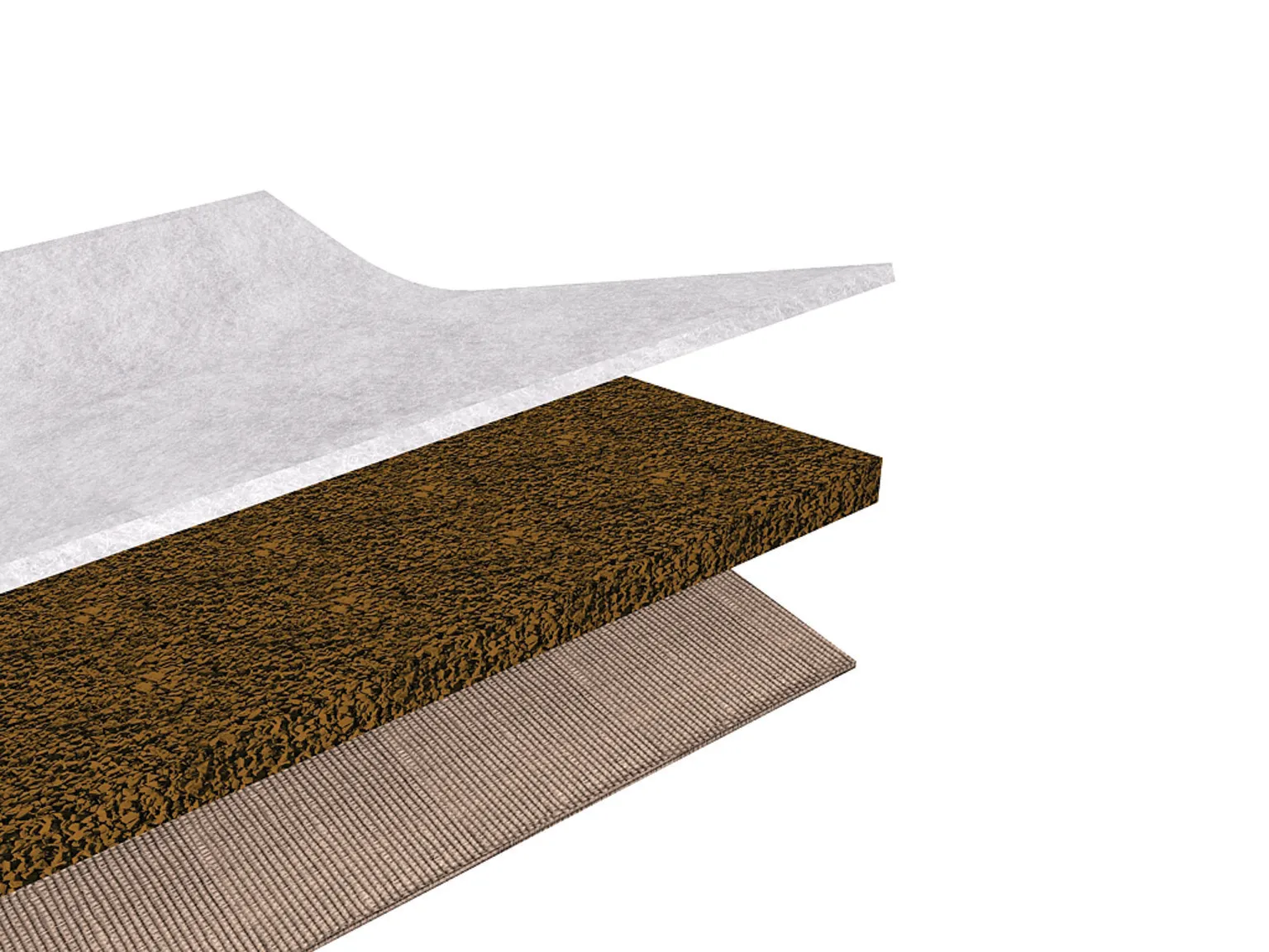

It is a multi-component system made from a high-tensile base, internal sealing material consisting of granulated sodium bentonite and a robust nonwoven as the top layer. A special precision-needling technique, based on state-of-the-art engineering, is used to join together the three components to produce a homogeneous, structurally continuous liner sheet.

As a result of the special manufacturing techniques, Tektoseal is not only described as very economical, it is also environmentally friendly. The extremely thin construction (< 10 mm) is said to achieve at least the same sealing effect as conventional clay liners. Furthermore, it produces very little dust and ITS optimum roll width of over 5m makes it quick and easy to install.